Composite catalyst for nitric oxide purification and application of composite catalyst

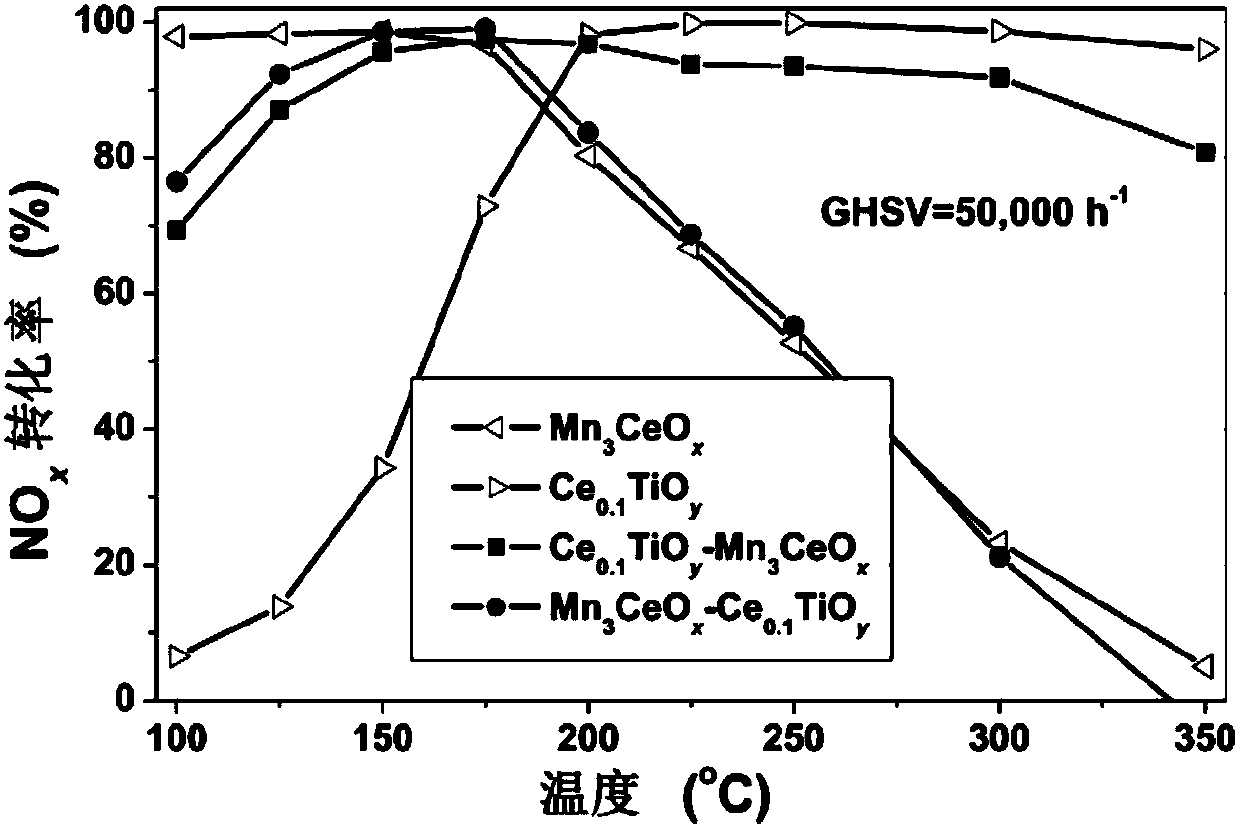

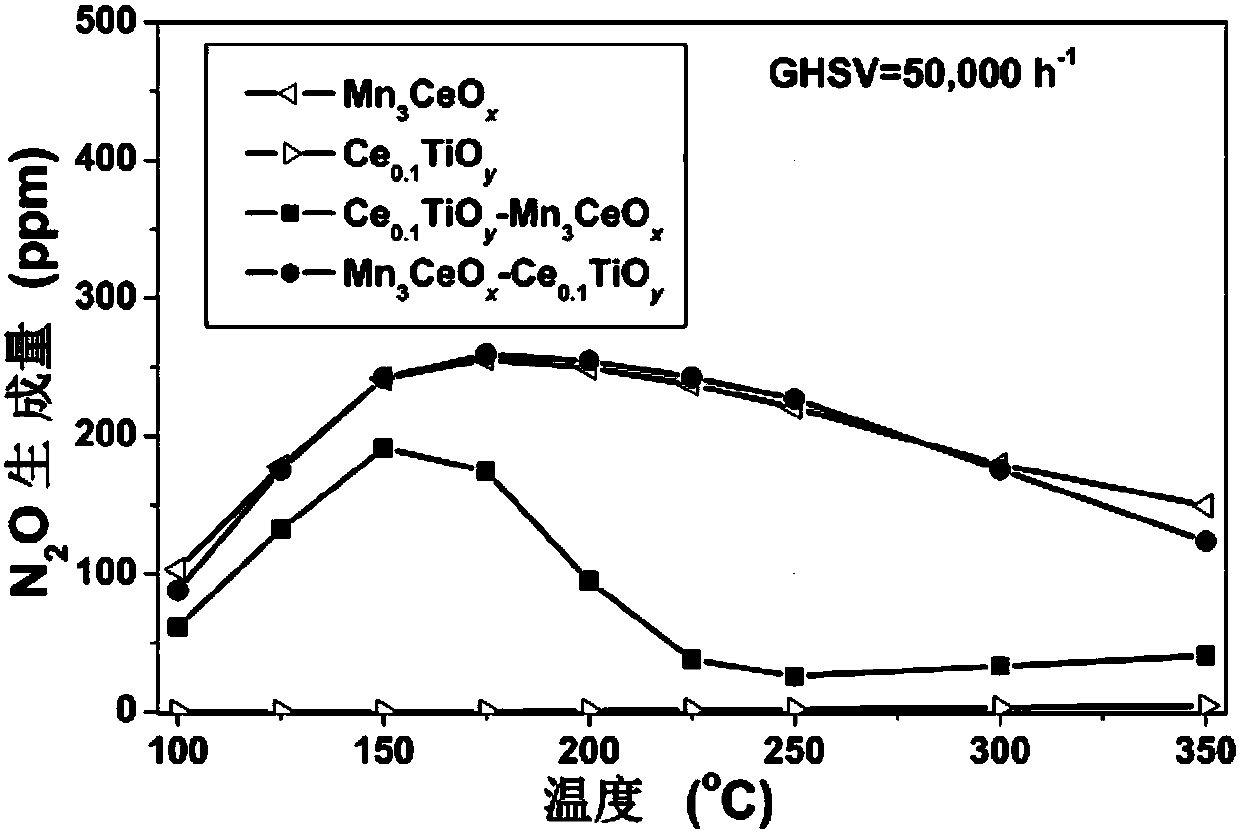

A technology combining catalysts and nitrogen oxides, applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, catalyst activation/preparation, etc., can solve the problem of reduced N2 selectivity and low-temperature activity that needs to be further improved Improvement, NO concentration is higher than the initial concentration, etc., to achieve excellent low-temperature activity and N2 generation selectivity, low generation amount, and high NOx conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] According to the Mn:Ce molar ratio of 3:1, prepare a mixed solution of manganese nitrate and cerium nitrate, then add excess urea, then heat to 80-90°C and continuously stir for 12 hours, then filter and wash, and put the obtained solid into an oven Dry at 100-110°C for 12 hours, and finally bake in air at 500°C for 5 hours in a muffle furnace to obtain a powder catalyst, called catalyst A, marked as Mn 3 CeO x .

Embodiment 2

[0059] According to the molar ratio of Ce and Ti is 0.1:1, dissolve titanium sulfate in deionized water, then add cerium nitrate, and add urea as a precipitant, control the pH value of the mixed solution after all dissolution is lower than 0.5, and then heat to 80 Stir continuously at ~90°C for 12h, the pH rises to above 7.0, then filter and wash, put the obtained solid in an oven and dry at 100-110°C for 12h, and finally roast in air at 500°C in a muffle furnace for 5h , a powdered catalyst was prepared, called Catalyst B, marked as Ce 0.1 TiO y .

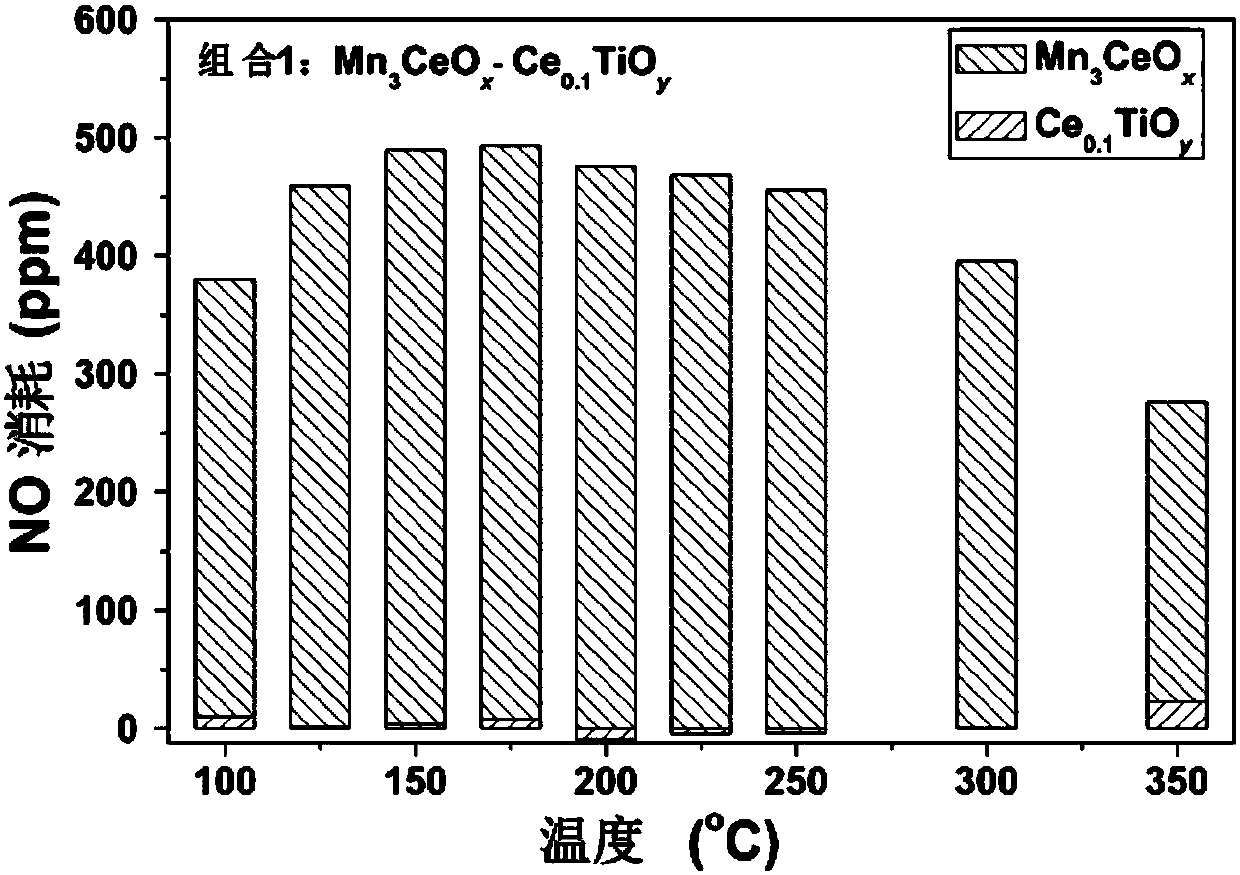

Embodiment 3

[0061] The prepared samples A and B were pressed into tablets, crushed and sieved, and the 40-60 mesh particles were used for catalyst combination. Place equal volumes of A at the front end and B at the back end to form catalyst combination 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com