Method for extracting ferulic acid from herba desmodii syracifolii

A technology for extracting ferulic acid from Desmodium stylifolia and ferulic acid, which can solve the problems of low solubility, cumbersome operation, and oil loss of aromatic compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for extracting ferulic acid from Desmodium glabra, specifically comprising the steps of:

[0025] 1) Clean Desmodium sativa, dry, pulverize with a pulverizer, and cross a 20-mesh sieve;

[0026] 2) Subcritical water extraction: place the processed raw materials in an extraction kettle, add hydroxyethyl cellulose equivalent to 0.001 parts by weight of the raw materials, inject deoxygenated deionized water into the kettle at a flow rate of less than 10mL / min, and extract at a temperature of 160-170°C, pressure 8-10Mpa, extraction time 0.5h, extract Desmodium sativa, after the extraction is completed, the pressure is released, the extract flows into the collection tank and cooled to room temperature to obtain the extract;

[0027] 3) Purification: Concentrate the extract obtained in step 2), control the temperature ≤ 50°C, control the vacuum at -0.08±0.01MPa, concentrate to 0.95-1.05g / ml, perform column chromatography through DM130 macroporous resin, and load the ...

Embodiment 2

[0029] A method for extracting ferulic acid from Desmodium glabra, specifically comprising the steps of:

[0030] 1) Clean Desmodium sativa, dry, pulverize with a pulverizer, and pass through a 40-mesh sieve;

[0031] 2) Subcritical water extraction: place the processed raw materials in an extraction kettle, add hydroxyethyl cellulose equivalent to 0.001 parts by weight of the raw materials, inject deoxygenated deionized water into the kettle at a flow rate of less than 10mL / min, and extract at a temperature of 160-170°C, pressure 8-10Mpa, extraction time 1.0h, extract Desmodium sativa, after the extraction is completed, the pressure is released, the extract flows into the collection tank and cooled to room temperature to obtain the extract;

[0032]3) Purification: Concentrate the extract obtained in step 2), control the temperature to ≤50°C, control the vacuum at -0.08±0.01MPa, concentrate to 0.95-1.05g / ml, and perform column chromatography through AB-8 macroporous resin, T...

Embodiment 3

[0034] A method for extracting ferulic acid from Desmodium glabra, specifically comprising the steps of:

[0035] 1) Clean Desmodium sativa, dry, pulverize with a pulverizer, and cross an 80-mesh sieve;

[0036] 2) Subcritical water extraction: place the processed raw materials in an extraction kettle, add hydroxyethyl cellulose equivalent to 0.001 parts by weight of the raw materials, inject deoxygenated deionized water into the kettle at a flow rate of less than 10mL / min, and extract at a temperature of 160-170°C, pressure 8-10Mpa, extraction time 1.0h, extract Desmodium sativa, after the extraction is completed, the pressure is released, the extract flows into the collection tank and cooled to room temperature to obtain the extract;

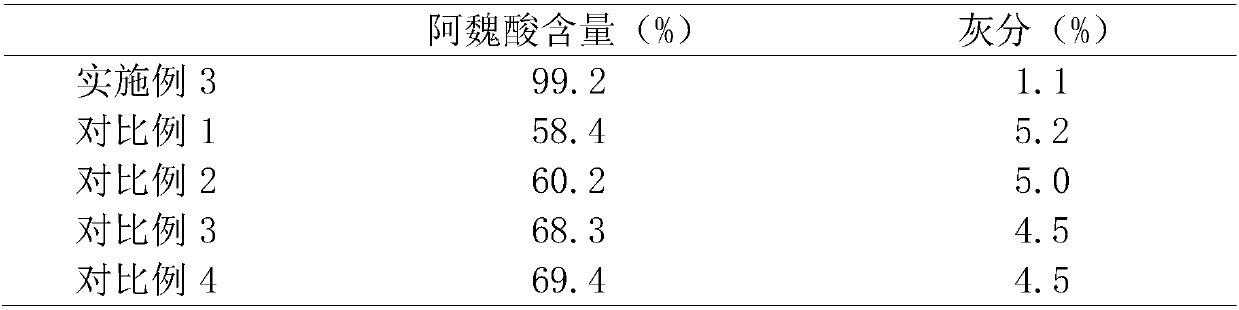

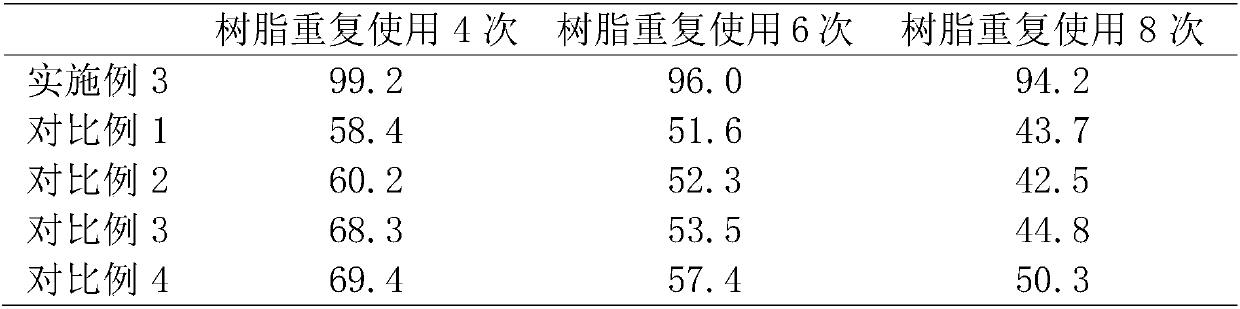

[0037] 3) Purification: Concentrate the extract obtained in step 2), control the temperature ≤ 50°C, control the vacuum at -0.08±0.01MPa, concentrate to 0.95-1.05g / ml, perform column chromatography through D101 macroporous resin, and load the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com