Curing powder coating for medium-density board and preparation method thereof

A powder coating, medium density technology, used in powder coatings, anti-corrosion coatings, polyester coatings, etc., can solve problems such as inability to use, and achieve the effect of reducing damage and reducing curing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

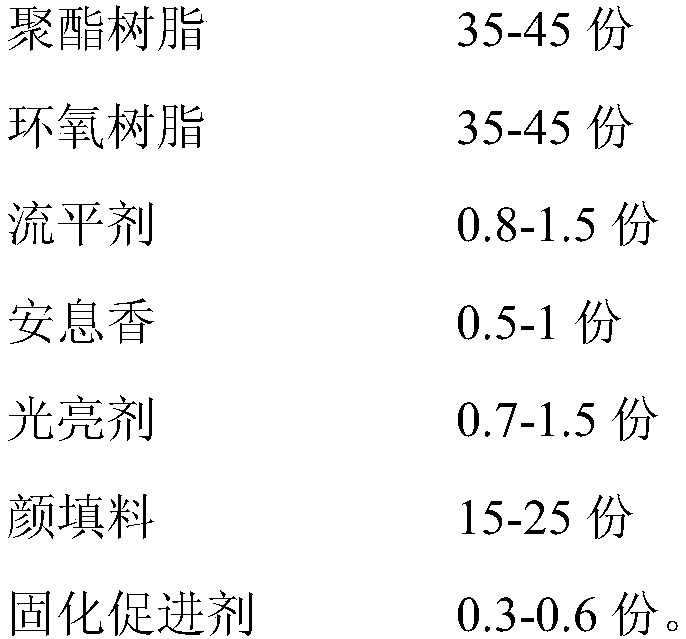

[0021]

[0022] Preparation process: The raw materials are mixed according to a certain weight ratio, mixed evenly in an automatic mixer, and then extruded in a thermosetting twin-screw extruder. The extrusion temperature is 95°C in the first zone, 95°C in the second zone, and 100°C in the third zone. After cooling, it is pulverized by a pulverizer, electrostatically sprayed, and baked. Baking conditions were 130° C. for 10 minutes to obtain samples.

Embodiment 2

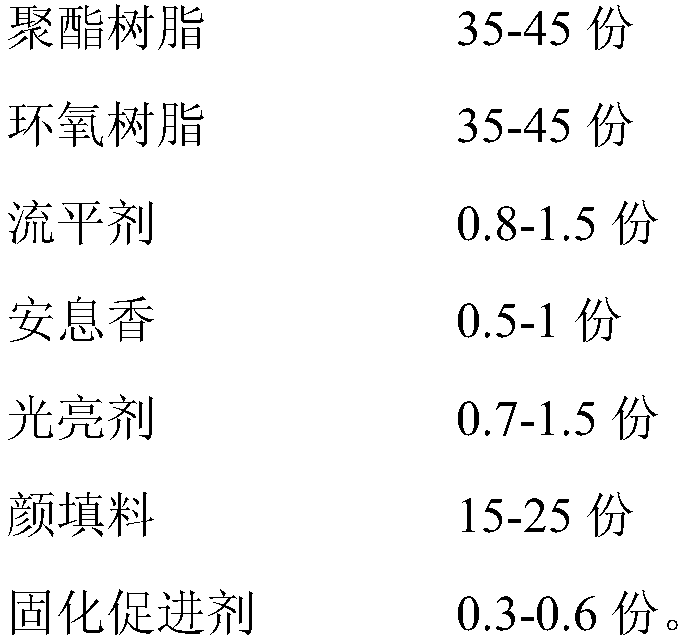

[0024]

[0025] The preparation process is the same as in Example 1.

Embodiment 3

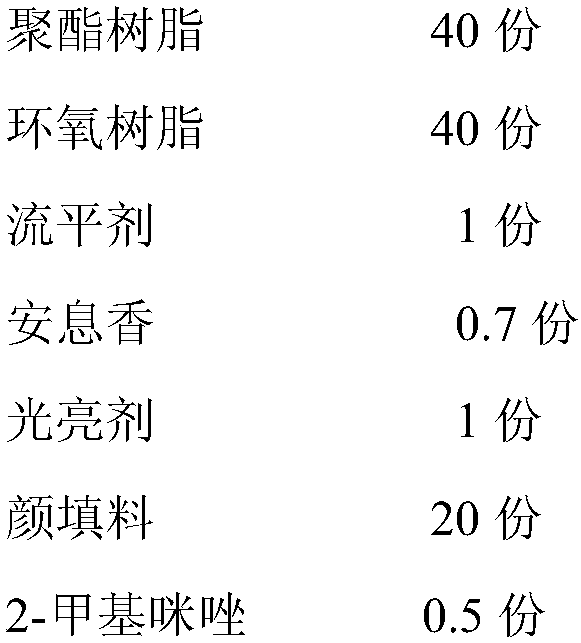

[0027]

[0028] The preparation process is the same as in Example 1.

[0029] The samples of the three examples have been tested, and the curability, adhesion, hardness, wear resistance, and corrosion resistance have all reached the effect of normal powder coatings at 180°C for 15 minutes, and can be sprayed on the surface of medium density boards without damaging the medium density. plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com