Integrated micro-hemispherical resonator gyro and processing and packaging method thereof

A hemispherical resonant gyro and overall technology, applied in the field of micro-electromechanical and inertial navigation, can solve the problems of gyroscope performance such as large surface roughness, difficult release process, and large size, and achieve shortened production cycle, long service life, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

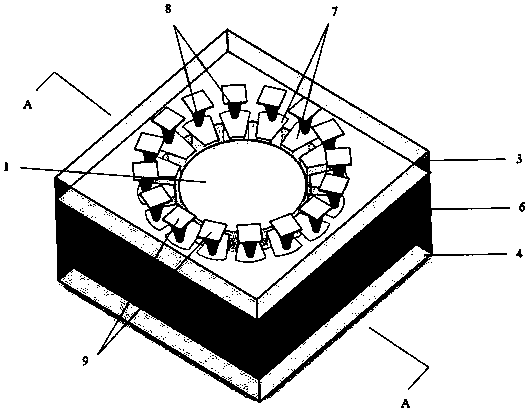

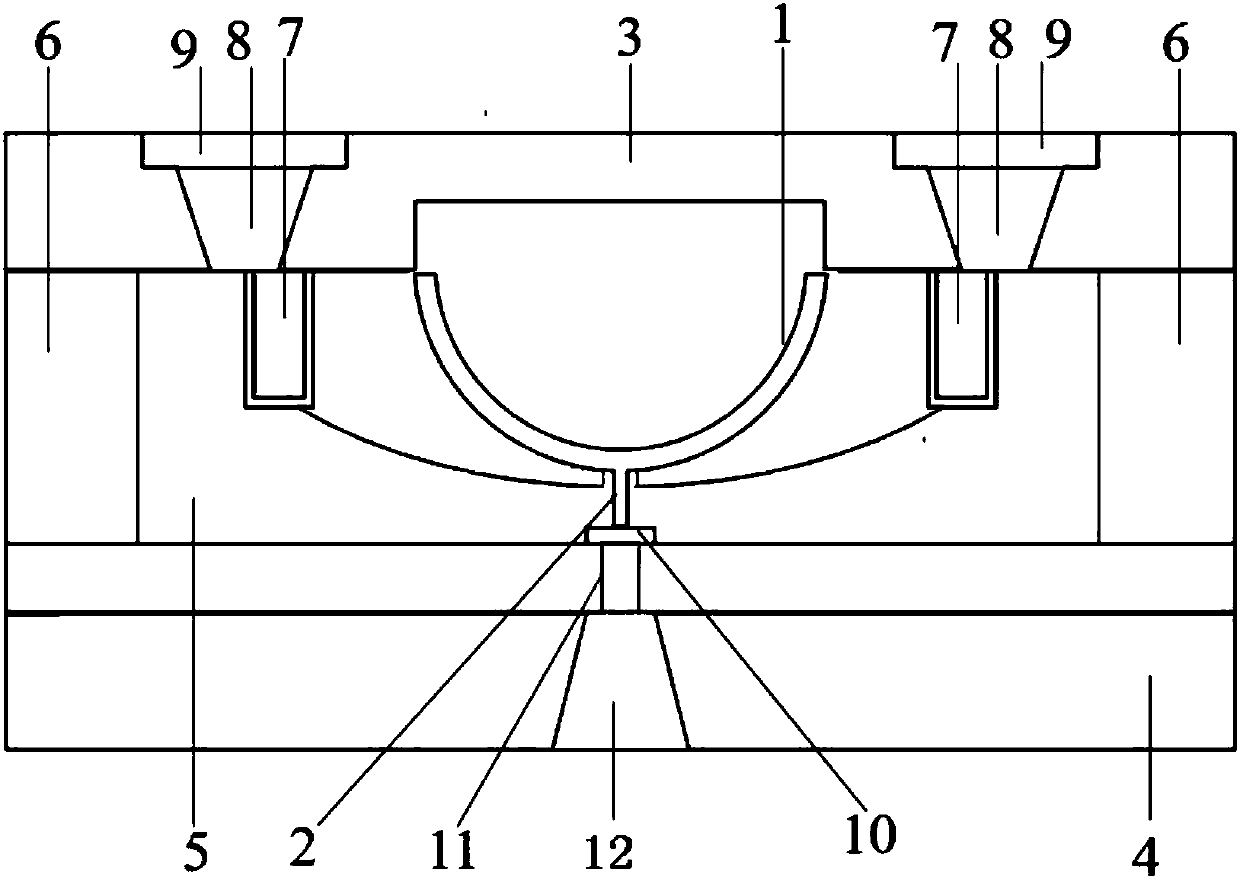

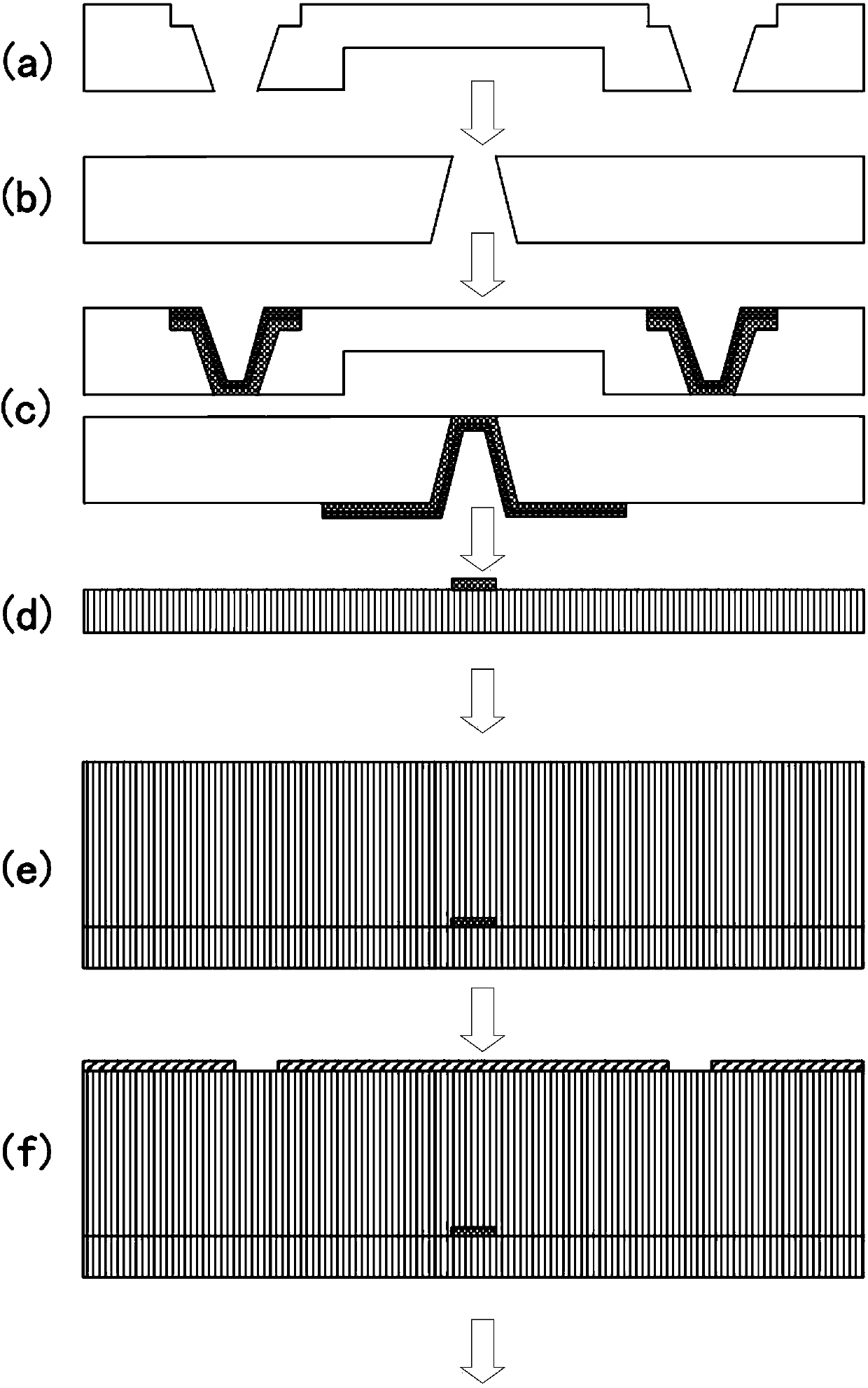

[0031] Such as Figure 1-2 As shown, an integral micro-hemispherical resonant gyroscope includes a hemispherical shell resonator 1, a support handle 2, an upper glass substrate 3, a lower glass substrate 4, an intermediate silicon substrate 5, a peripheral anchor structure 6, electrodes 7, The first electrode hole 8, the pad 9, the metal mask layer 10, the metal lead 11 and the second electrode hole 12; the upper glass substrate 3, the intermediate silicon substrate 5 and the lower glass substrate 4 are from top to bottom Arranged in sequence, the peripheral anchor structure 6 is arranged on the outer periphery of the intermediate silicon substrate 5; the middle part of the intermediate silicon substrate 5 is a hollow cavity, and the hemispherical shell resonator 1 is arranged in the central part of the hollow cavity; the intermediate silicon substrate 5 Sixteen electrodes 7 are evenly arranged along the outer periphery of the hemispherical shell resonator 1; the upper glass s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com