Acetone gas sensor of LaFeO3 nano sensitive material based on nuclear shell microsphere structure and its preparation method

A technology for gas sensors and sensitive materials, applied in nanotechnology, chemical instruments and methods, and nanotechnology for materials and surface science, can solve the problems of unsatisfactory detection gas sensitivity results, achieve small size, simple operation, The effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

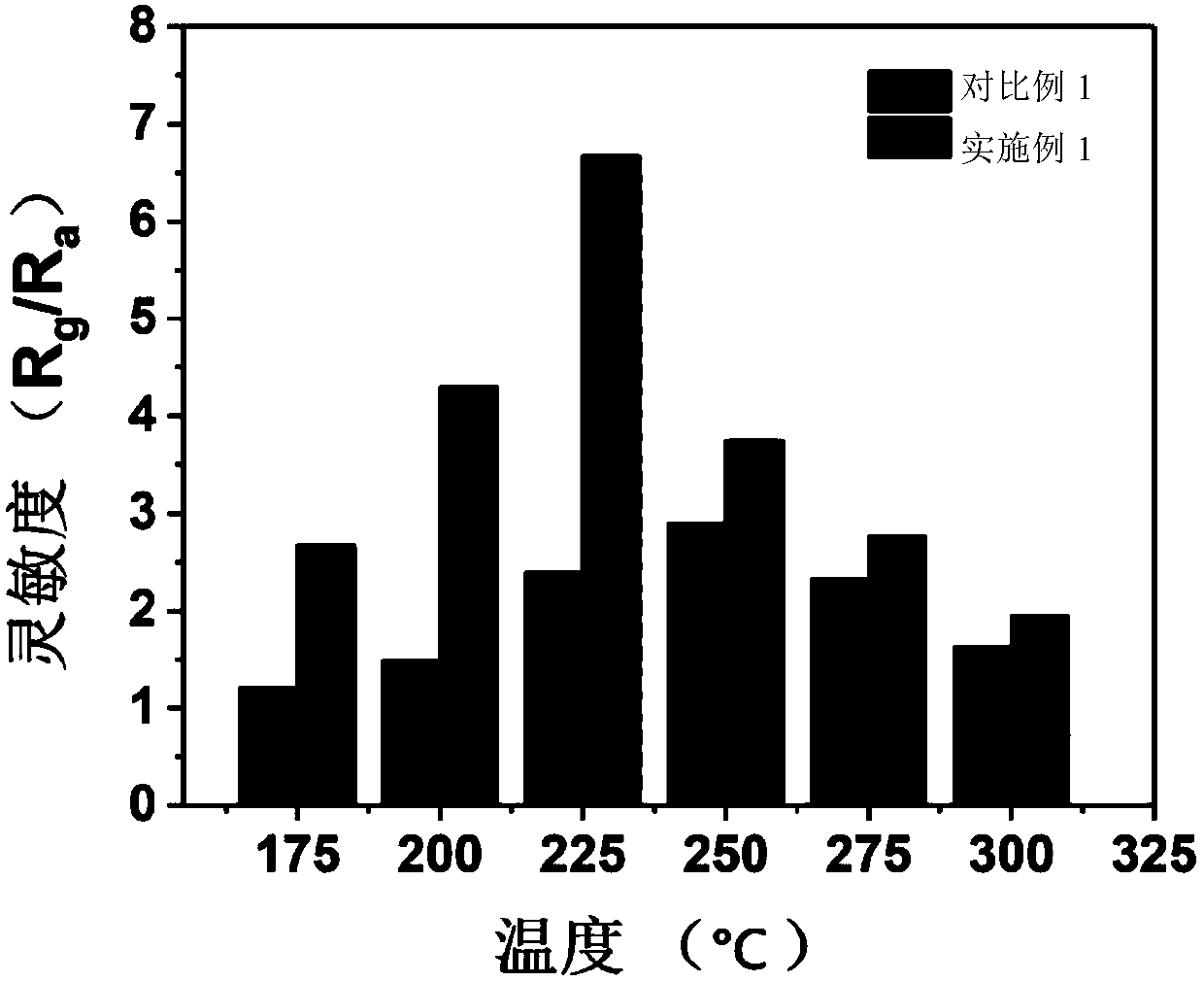

Embodiment 1

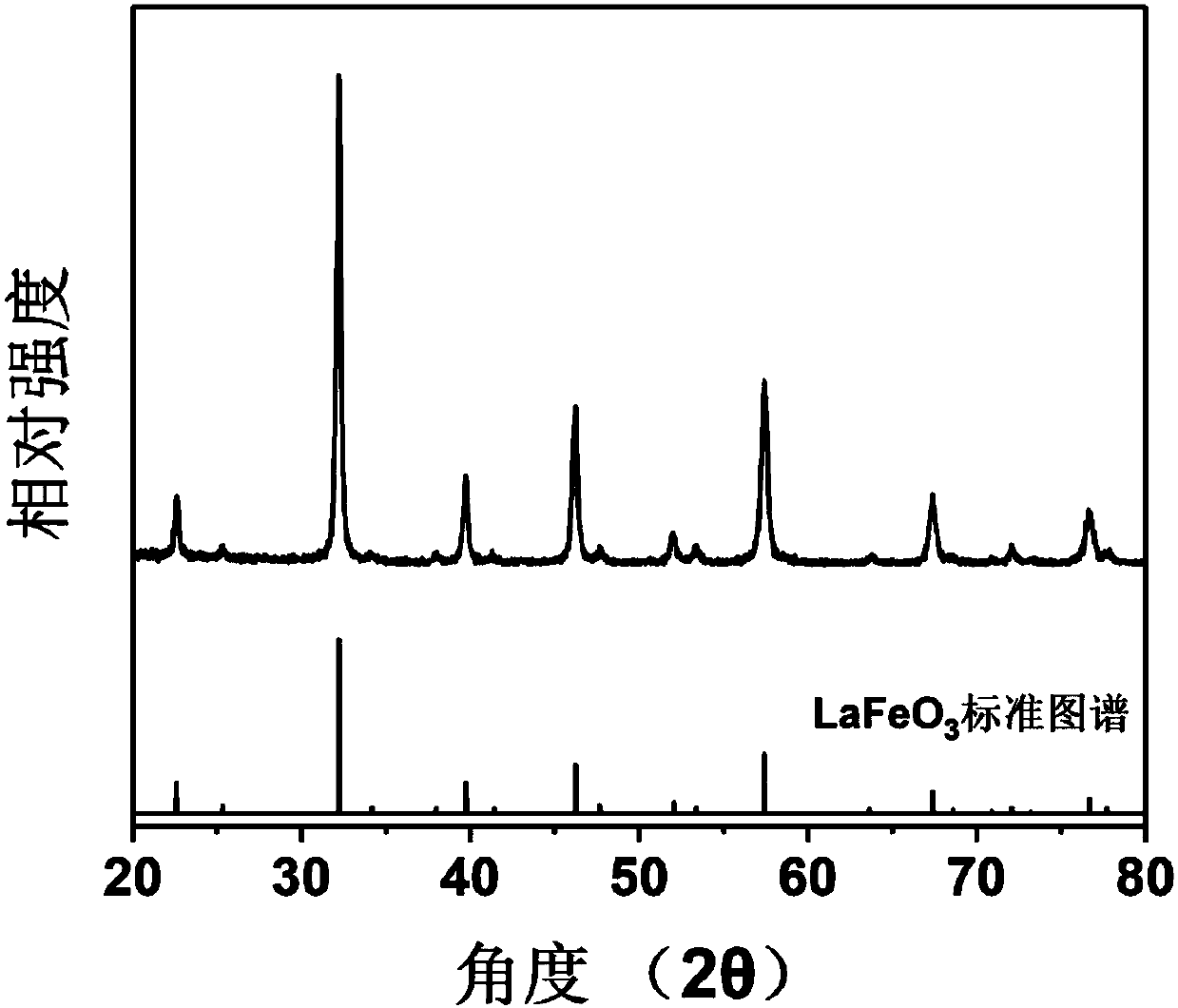

[0038] LaFeO with core-shell microsphere structure prepared by a long-term hydrothermal reaction 3 The acetone gas sensor is a sensitive material, and its specific manufacturing process is as follows:

[0039] 1) First, 0.32g of La(NO 3 ) 3 ·6H 2 O and 0.3g Fe(NO 3 ) 3 9H 2 Dissolve O in 40mL of a mixed solution of water and ethylene glycol (volume ratio 19:1), stir for 30min, then add 0.16g of citric acid and 0.6g of PVP, and continue stirring for 30min.

[0040] 2) Put the solution obtained in step 1 into a 50mL polytetrafluoroethylene kettle liner, seal it, put it into a stainless steel reaction kettle and tighten the lid, transfer it to an oven and react at 140°C for 12h. After the reaction was completed and cooled to room temperature naturally, the sediment on the bottom of the kettle was retained, washed repeatedly by centrifugation with ethanol and deionized water for 6 times, and then dried in air at 80°C for 12 hours.

[0041] 3) Put the powder obtained in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com