Photosensitive resin composition and color filter comprising same

A technology of photosensitive resin and composition, applied in the field of photosensitive resin composition, can solve problems such as freedom degree limitation, and achieve the effect of improving brightness and reducing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

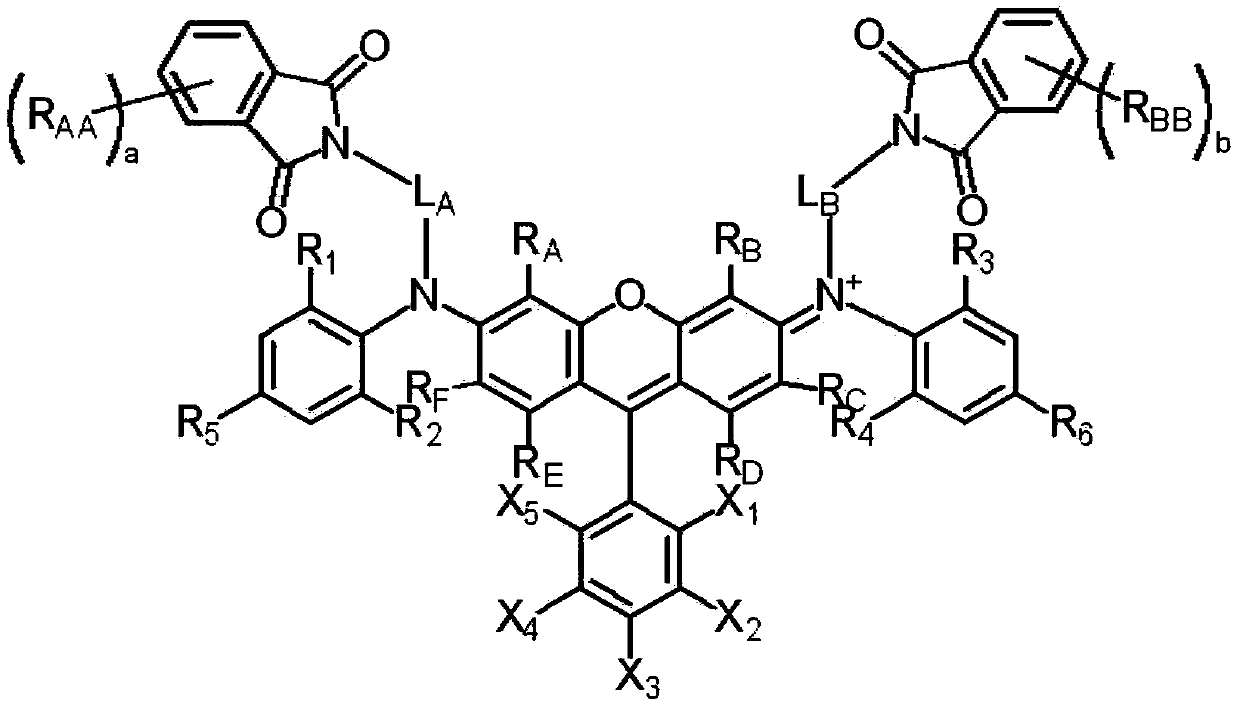

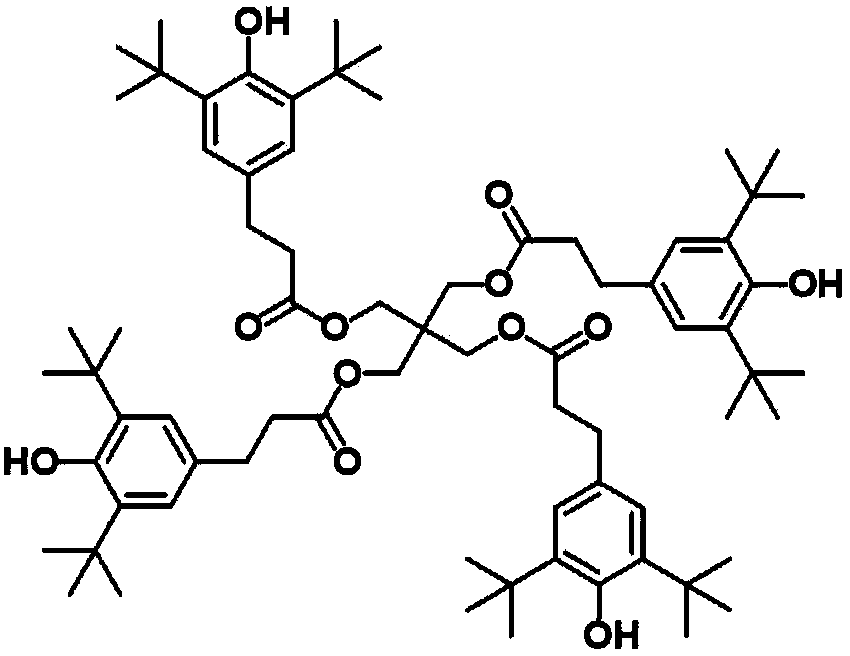

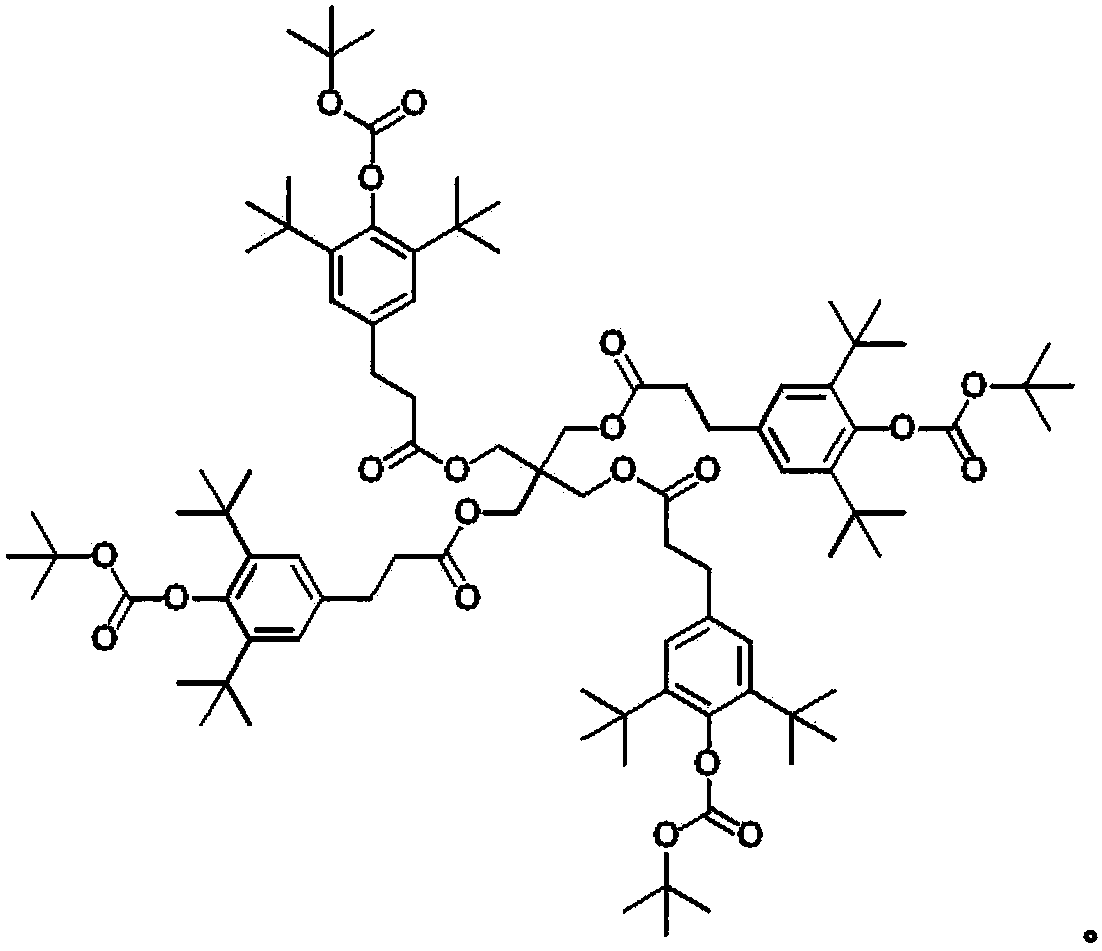

Method used

Image

Examples

experiment example

[0193] Examples 1-4 and Comparative Examples 1-3 were produced by the ratio shown in following Table 1. The feeding unit of each composition is gram (g).

[0194] [Table 1]

[0195] [Table 1]

[0196]

[0197] Production of the substrate

[0198] The produced photosensitive resin composition was spin-coated (spincoated) on glass (5x5 cm), and it prebaked at 110 degreeC for 70 second, and formed a film. The distance between the substrate on which the film was formed and the photomask (photo mask) was set to 300 μm, and the entire surface of the substrate was irradiated with 30 mJ / cm using an exposure machine. 2 exposure.

[0199] Next, the exposed substrate was developed for 55 seconds with a developing solution (KOH, 0.04%), and post-baked at 230° C. for 20 minutes to prepare a substrate.

experiment example 1

[0200] Experimental example 1. Measurement of brightness

[0201] The color characteristics of the prepared substrates were confirmed using a spectrophotometer, and the luminance values are shown in the following [Table 2].

experiment example 2

[0202] Experimental example 2. Measurement of heat resistance

[0203] For the above prepared substrate, the color characteristics were confirmed using a spectrophotometer, and after further heat treatment for 1 hour in a convection oven (convection oven) at 230°C, the color characteristics were confirmed again, and the ΔEab value was obtained and shown in the following [Table 2 ].

[0204] [Table 2]

[0205] [Table 2]

[0206]

[0207] As shown in the above Table 2, it can be seen that when the photosensitive resin composition of Examples 1 to 4 containing both the compound represented by the above Chemical Formula 1 and the antioxidant is used to manufacture a color filter, the brightness and heat resistance characteristics are improved. Effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com