Flue gas pollutant purifying tower

A purification tower and pollutant technology, applied in the field of flue gas purification, can solve the problem that the adsorbent cannot be fully utilized, and achieve the effects of high utilization rate of the purifying agent, smooth operation of the flue gas, and improved removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

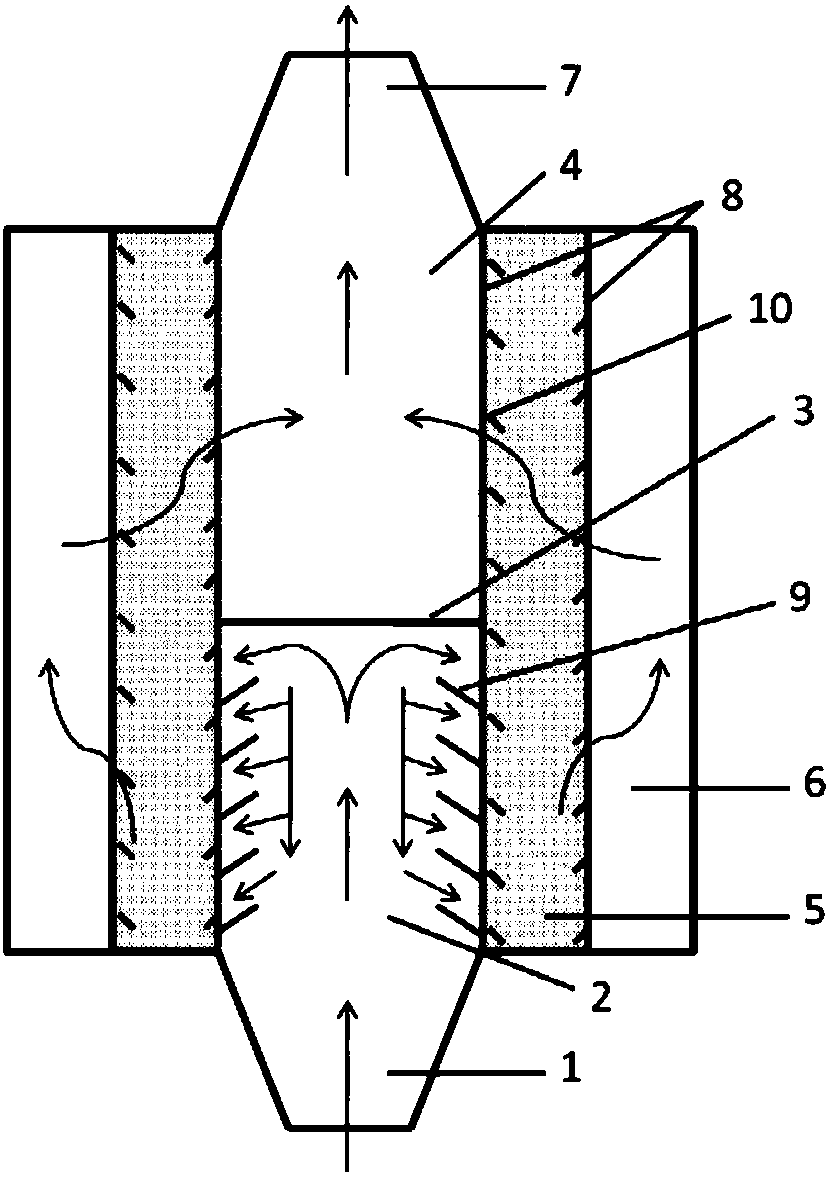

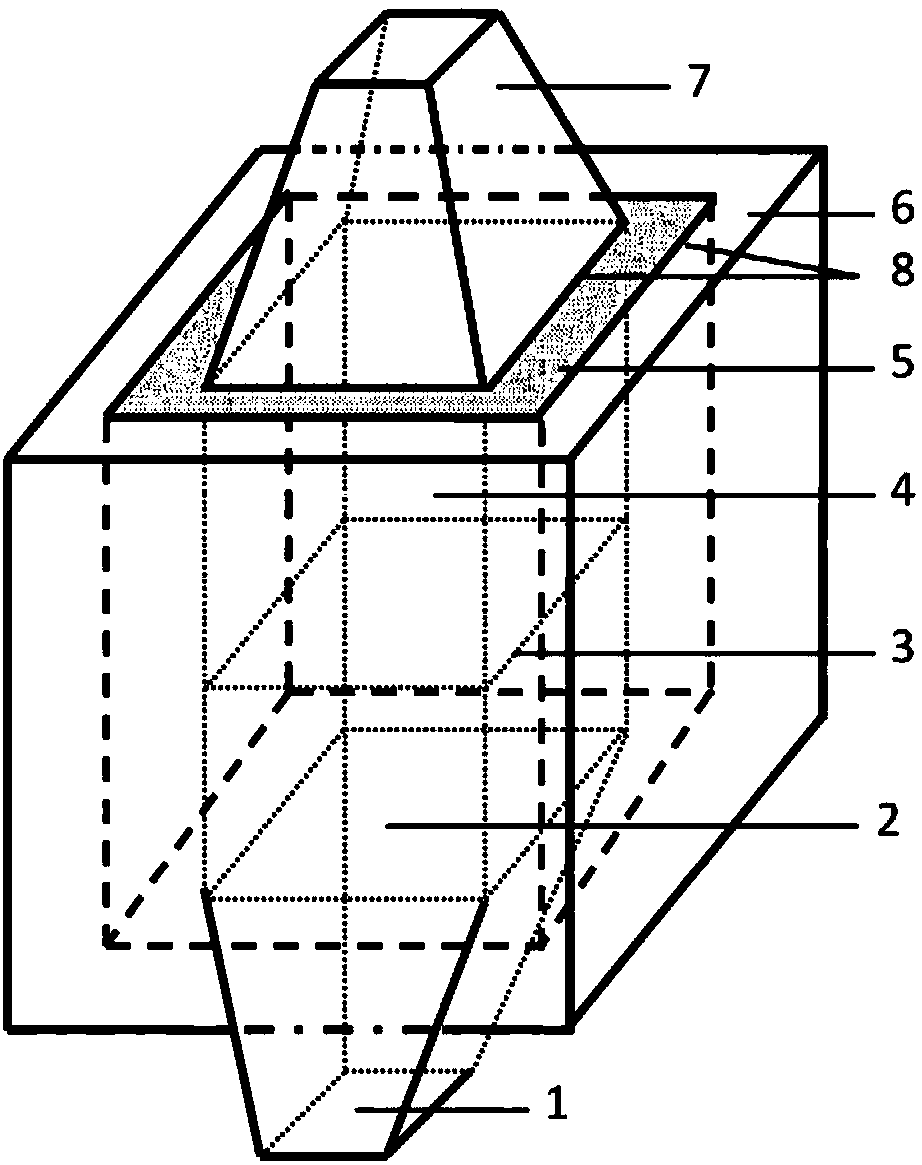

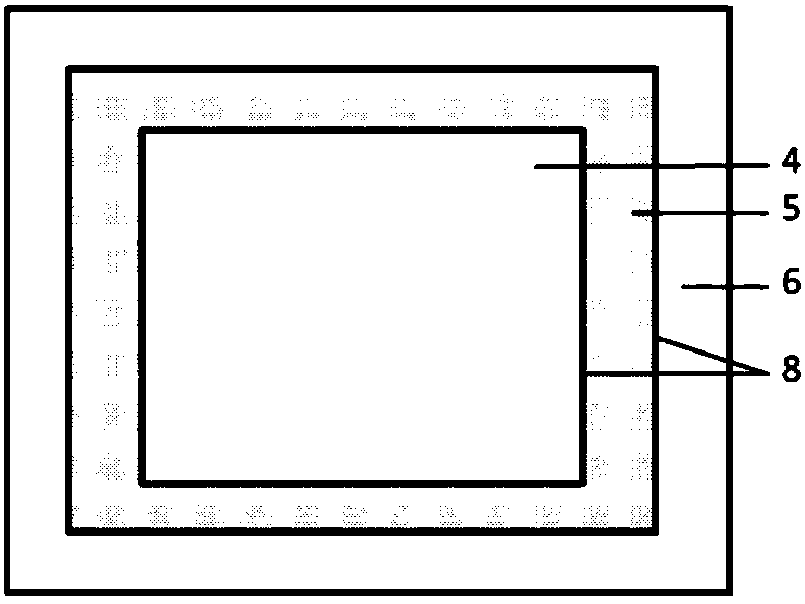

[0051] This embodiment provides a flue gas pollutant purification tower, its structure is as follows: figure 1 , figure 2 and image 3 As shown, the purification tower body is a cuboid, adopting a fixed bed structure; the purifying agent area is also a cuboid structure, with a thickness of 2m; the middle height of the purifying agent area is twice the thickness of the purifying agent layer, and the top and The height of the bottom is the same; the opening ratio of the top and the bottom is 55%, and the opening ratio of the middle part is 8%; the aperture on the perforated plate 8 is 4mm; The included angle is 35 °; the length of the wing plate 10 is 10 cm, and the included angle with the vertical downward direction is 15 °; the cleaning agent 5 in the interlayer of the porous plate 8 is a cylindrical activated coke / carbon with a diameter of 5 mm.

[0052] Use the above flue gas pollutant purification tower to remove dioxin and mercury in the flue gas, with a flue gas volum...

Embodiment 2

[0055] This embodiment provides a flue gas pollutant purification tower, its structure is as follows: figure 1 , figure 2 and image 3 As shown, the body of the purification tower is a cuboid with a fixed bed structure; the purifying agent area is also a cuboid structure with a thickness of 1.5m; the middle height of the purifying agent area is 3 times the thickness of the purifying agent layer, and the top Identical with the height of the bottom; The opening ratio of the top is 45%, the opening ratio of the bottom is 50%, and the opening ratio of the middle part is 10%; The aperture on the perforated plate 8 is 3mm; The angle in the vertical upward direction is 40 °; the length of the wing plate 10 is 8 cm, and the angle with the vertical downward direction is 18 °; the cleaning agent 5 in the interlayer of the porous plate 8 is a cylindrical blue carbon with a diameter of 5 mm.

[0056] Use the above flue gas pollutant purification tower to remove dioxin and mercury in t...

Embodiment 3

[0059] This embodiment provides a flue gas pollutant purification tower, its structure is as follows: figure 1 , figure 2 and image 3 As shown, the body of the purification tower is a cuboid with a fixed bed structure; the purifying agent area is also a cuboid structure with a thickness of 2.5m; the middle height of the purifying agent area is 1.5 times the thickness of the purifying agent layer, and the top The same height as the bottom; the opening rate of the top is 55%, the opening rate of the bottom is 45%, and the opening rate of the middle part is 15%; the aperture on the perforated plate 8 is 5mm; the length of the louver wing plate 9 is 12cm, the angle with the vertical upward direction is 45 °; the length of the wing plate 10 is 5 cm, and the angle with the vertical downward direction is 25 °; the cleaning agent 5 in the perforated plate 8 interlayer is a cylindrical active material with a diameter of 7 mm. Coke / Charcoal.

[0060] Use the above flue gas polluta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com