Manufacturing method of ice-making drum and same

A manufacturing method and drum technology, applied in ice making, ice making, applications, etc., can solve the problems of low cooling and ice making efficiency, low thermal conductivity of stainless steel materials, complicated manufacturing engineering, etc., and achieve excellent cooling efficiency, excellent manufacturing performance, The effect of solid structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

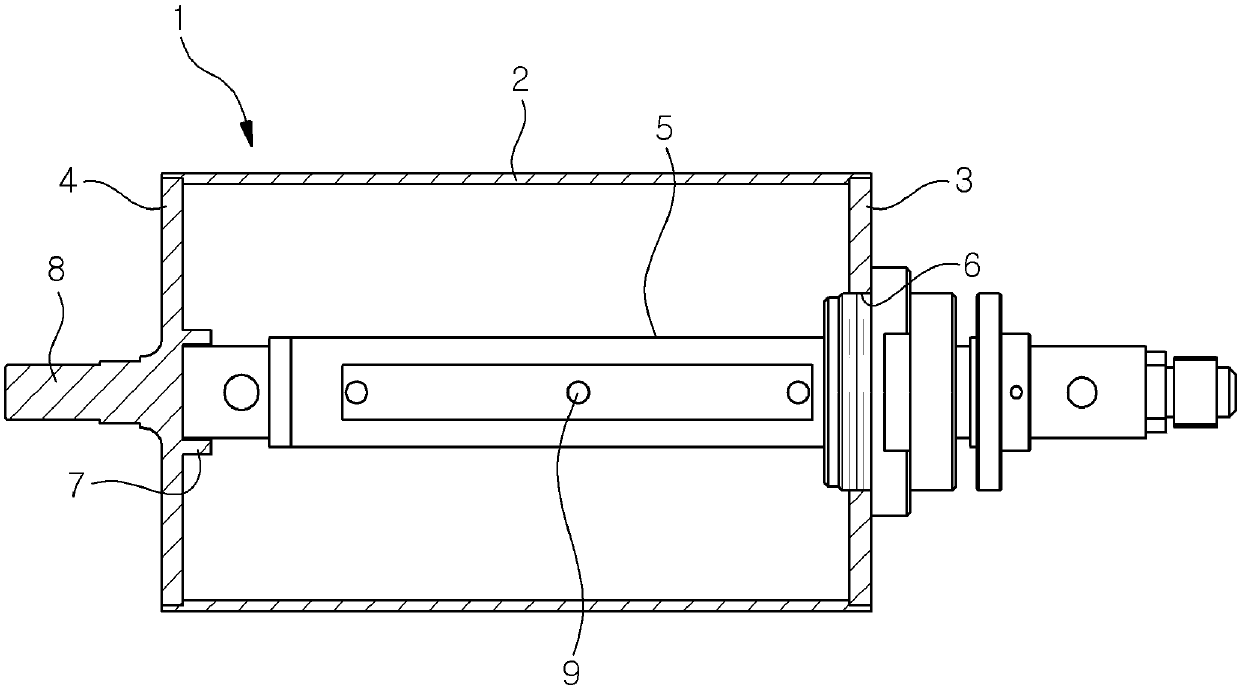

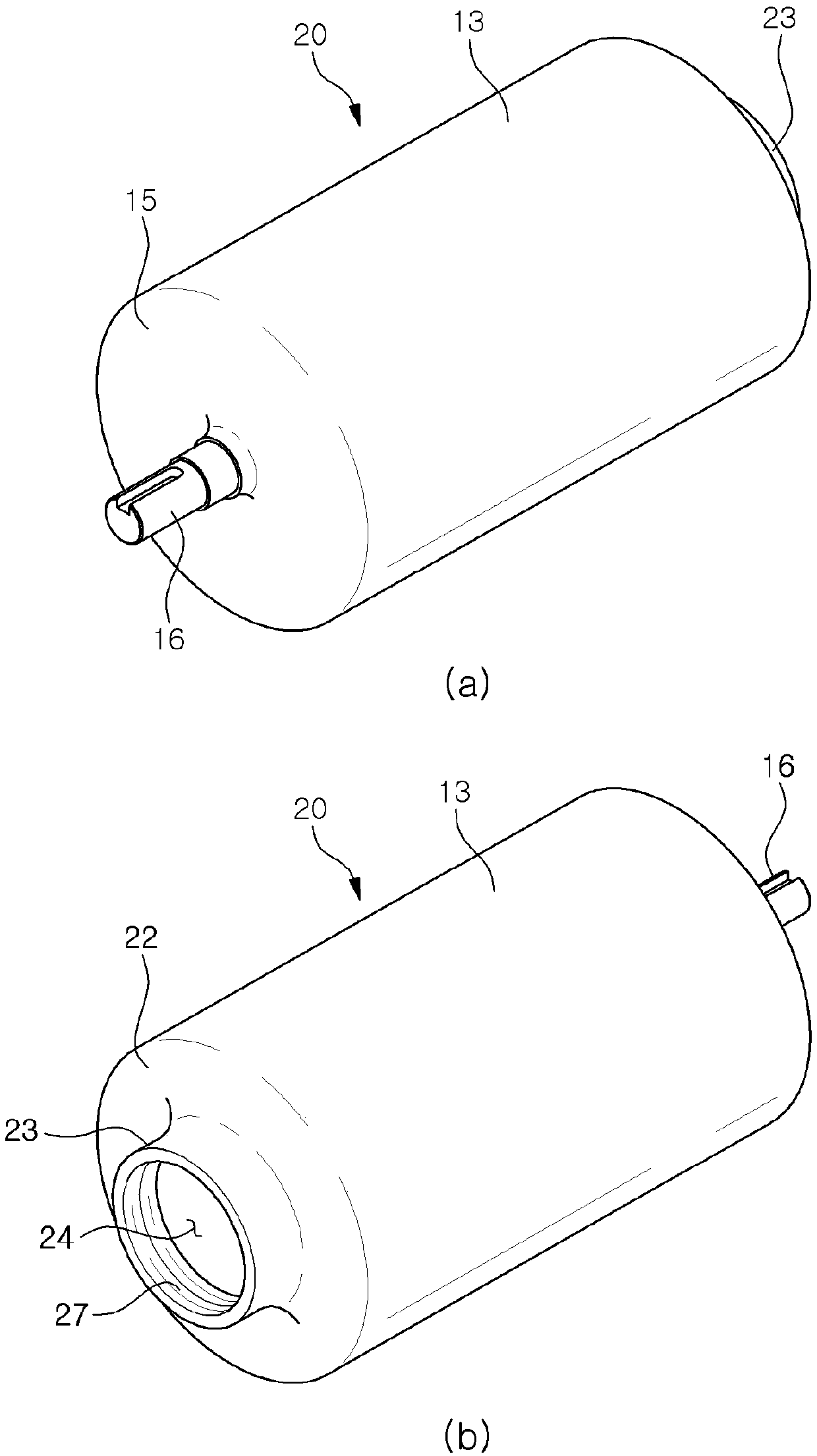

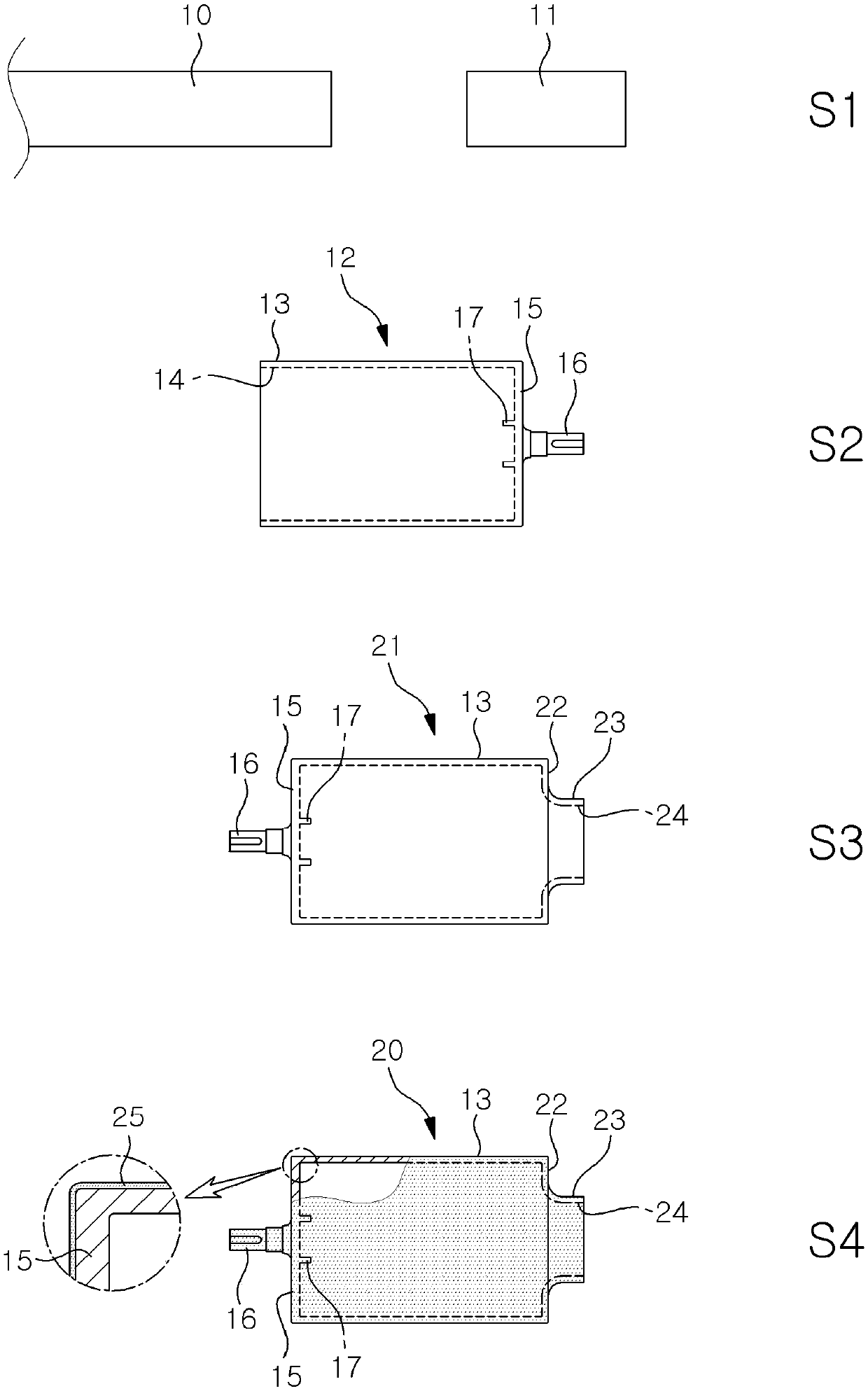

[0018] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings. figure 2 is an appearance view of an ice-making drum according to an embodiment of the present invention; image 3 is a manufacturing engineering drawing of an embodiment of the present invention; Figure 4 is a cross-sectional view of an ice-making drum made according to the present invention.

[0019] Such as image 3 As shown, the manufacturing method of the ice-making roller of the present invention includes: cutting the aluminum round rod 10 into specifications for release, and preparing a stage of forming material blocks 11 with a certain size (S1). Preferably, before forging, the formed material block 11 obtained above is pre-treated, that is, annealed heat treatment is performed to remove residual stress inside the material, or to improve the softness of the material, and to apply a lubricant on the surface.

[0020] Next, the molding material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com