High-strength anti-permeability leak-repairing material and preparation method thereof

A leak-trapping, high-strength technology, applied in the field of high-strength anti-seepage leak-trapping materials and their preparation, can solve the problems of unsuitable repair work, etc., and achieve the effects of long-lasting waterproof and anti-seepage performance, good weather resistance, and rapid molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preparation method of a high-strength anti-seepage leakage repairing material, comprising the steps of:

[0035] Put half of the total weight of cement and half of the total weight of quartz sand into the mixer and stir and mix for 10 minutes to prepare the main material mixture, wherein the stirring speed is 20r / min;

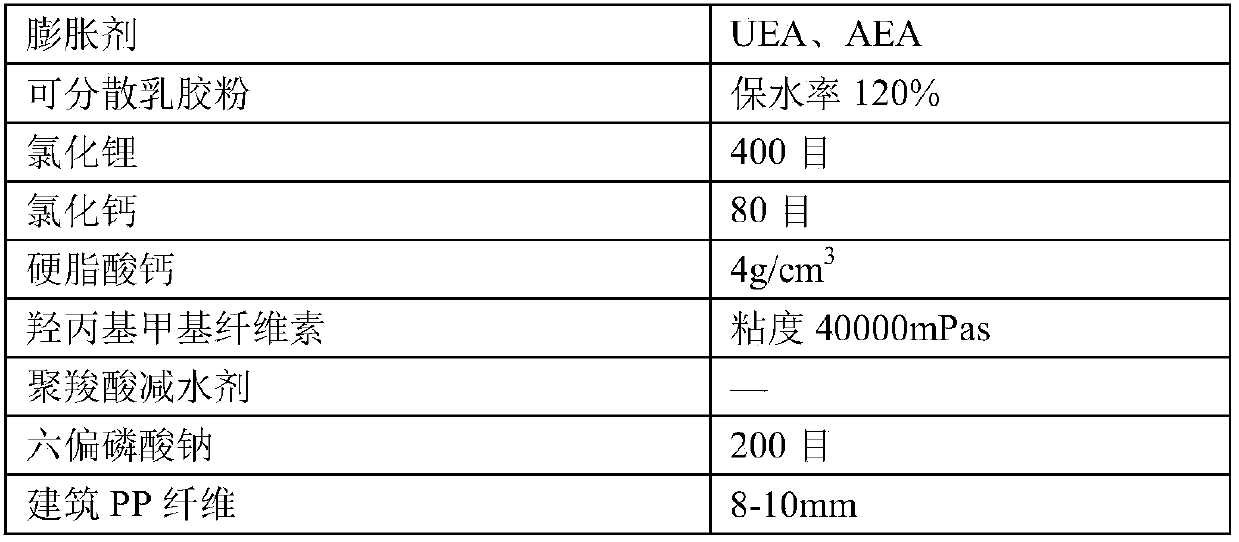

[0036] Swelling agent, dispersible latex powder, lithium chloride, calcium chloride, calcium stearate, hydroxypropyl methylcellulose, sodium hexametaphosphate, construction polypropylene fiber and water reducer are added in turn to the main material mixture and stirred and mixed 10min, make auxiliary material mixture, wherein stirring speed is 25r / min;

[0037] Add the remaining cement and quartz sand to the auxiliary material mixture and stir and mix for 20 minutes (stirring speed is 30r / min) to prepare a high-strength anti-seepage and leakage repairing material.

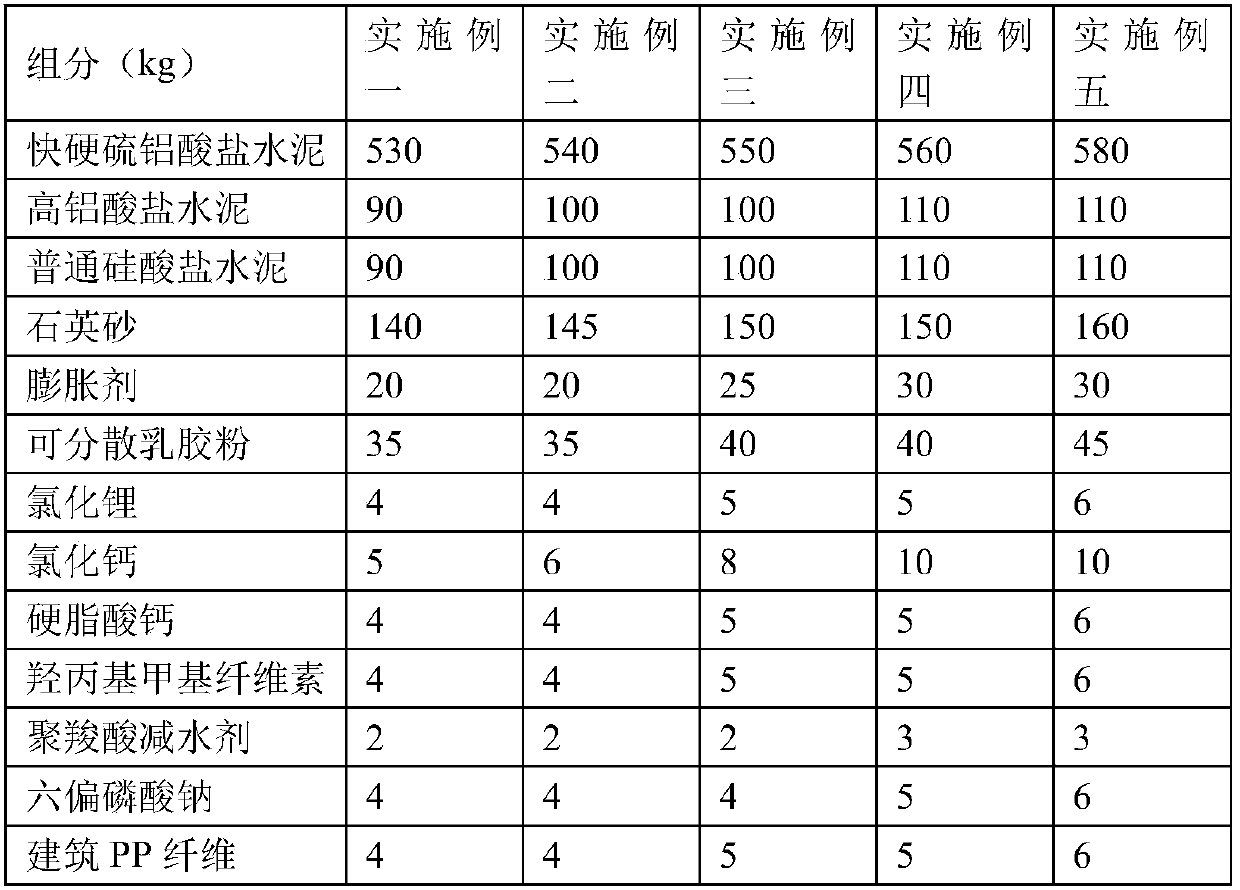

[0038] Example 1 to Example 5 High-strength anti-seepage and leak-remediation material...

Embodiment 3

[0048] The performance of the high-strength anti-seepage and leak-remediation material prepared in Example 3 is the best. Taking the high-strength anti-seepage and leak-remediation material prepared in Example 3 as an example, the repair work of waterproofing and leak-proofing at the pipe root is carried out.

[0049] Clean and level the base surface to be constructed, and remove floating ash and oil stains, take high-strength anti-seepage leakage repairing material and pure water with a volume ratio of 1:0.4, pour the high-strength anti-seepage leakage repairing material into pure water and stir until there is no agglomeration, and obtain high-strength anti-seepage leakage repairing material Anti-seepage leakage repair slurry.

[0050] According to the conventional treatment method, remove the groove at the position to be repaired, fill the groove with high-strength anti-seepage and leakage repairing slurry in a diagonal direction or circular rotation, and use a caulking knife...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com