A kind of uncolored poplar wood pulp and its production process

A natural and wood pulp technology, applied in post-treatment modification of cellulose pulp, washing/replacing pulp treatment liquid, papermaking, etc., can solve the problem of not having a natural and retro style, non-recyclable black liquor, and difficult to obtain bulk. Improve and other problems to achieve the effect of inhibiting peeling reaction, protecting fibers, and feeling soft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

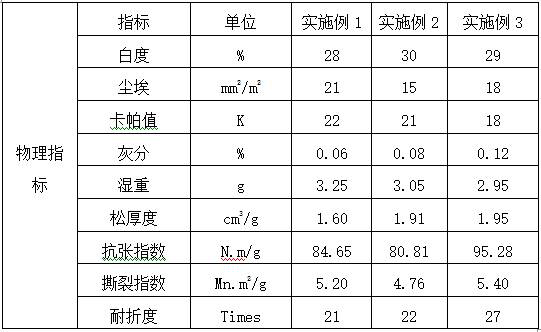

Examples

Embodiment 1

[0053] Embodiment 1 A kind of production technology of uncolored poplar wood pulp

[0054] Include the following steps:

[0055] The second invention purpose of the present invention is to provide a kind of production technology of uncolored poplar wood pulp, specifically comprises the following steps:

[0056] (1) Cooking: Transport the poplar slices to the screw conveyor by dragging, and add the prepared lye and cooking aids in the middle of the screw conveyor; the poplar slices are mixed with lye and cooking aids in the screw conveyor After mixing evenly, put the mixed poplar slices into steaming balls through a baller for steaming;

[0057] The poplar wood slices meet the following criteria: moisture content 22%, thickness between 0.8 mm, no impurities and bark, no black rot.

[0058] The temperature of the lye added to the screw conveyor is 80°C;

[0059] Wherein, the throwing amount (air-dried) of poplar slices in the steamed ball is 8.5t / ball;

[0060] The amount of...

Embodiment 2

[0081] Embodiment 2 A kind of production technology of uncolored poplar wood pulp

[0082] Include the following steps:

[0083] (1) Cooking: Transport the poplar slices to the screw conveyor by dragging, and add the prepared lye and cooking aids in the middle of the screw conveyor; the poplar slices are mixed with the lye and cooking aids in the screw conveyor After mixing evenly, put the mixed poplar slices into steaming balls through a ball loader, and cook; the poplar slices meet the indicators: moisture 18%, thickness 1.2-1.5mm, no impurities and bark, no black rot; The temperature of the lye added to the screw conveyor is 100°C; the amount of poplar slices in the steamed ball (air-dried) is 9.0t / ball; the amount of alkali used for cooking is 22%; the ratio of cooking liquid is 1:3;

[0084] The consumption of the cooking aid is 7.5kg / ball; the cooking agent is a new type of anthraquinone, preferably produced by Henan Hongruide New Material Technology Co., Ltd; %, effec...

Embodiment 3

[0091] Embodiment 3 A kind of production technology of uncolored poplar wood pulp

[0092] Include the following steps:

[0093] (1) Cooking: Transport the poplar slices to the screw conveyor by dragging, and add the prepared lye and cooking aids in the middle of the screw conveyor; the poplar slices are mixed with the lye and cooking aids in the screw conveyor After mixing evenly, put the mixed poplar slices into steaming balls through a baller for steaming;

[0094] The indicators that the poplar slices meet: moisture 23%, thickness between 1.0-1.4mm, no impurities and bark, no black rot; the temperature of the lye added to the screw conveyor is 100°C; the poplar slices in the steaming ball The amount of balls thrown (air-dried) is 8.5t / ball; the amount of alkali used for cooking is 20%; the ratio of cooking liquid is 1:2;

[0095] The consumption of the cooking aid is 8.0kg / ball; the new type of anthraquinone as the cooking agent is preferably produced by Henan Hongruide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com