Composite packing column mechanism, immobilization method of bacteria and leachate treatment method

A technology of composite filler and bacteria, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of long start-up time, system activity inhibition, short start-up time, etc., and achieve stability Oxidation effect, high application potential, short start-up time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

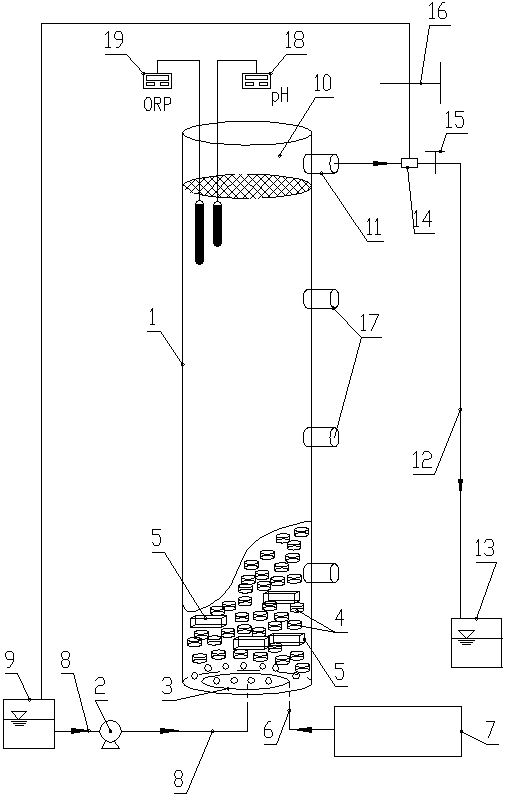

[0043] figure 1 The direction indicated by the middle arrow is the flow direction of the fluid.

[0044] Such as Figure 1 to Figure 5 As shown, the present invention provides a composite packing column mechanism, including a housing 1 and a peristaltic pump 2, and the housing 1 is provided with an annular microporous aeration tube 3 and composite packing from bottom to top, and the microporous aeration tube 3 Horizontally arranged, the composite filler includes uniformly mixed K3 filler 4 and modified polyurethane foam filler 5, and the bulk volume ratio of K3 filler 4 and modified polyurethane foam filler 5 is 3:1;

[0045] The microporous aeration pipe 3 is connected to an air pump 7 through a ventilation pipe 6, the bottom of the housing 1 is connected to the outlet of the peristaltic pump 2 through a pipe 8, and the inlet of the peristaltic pump 2 is connected to a stock solution pool 9 through a pipe;

[0046] The top of the composite packing is lower than the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com