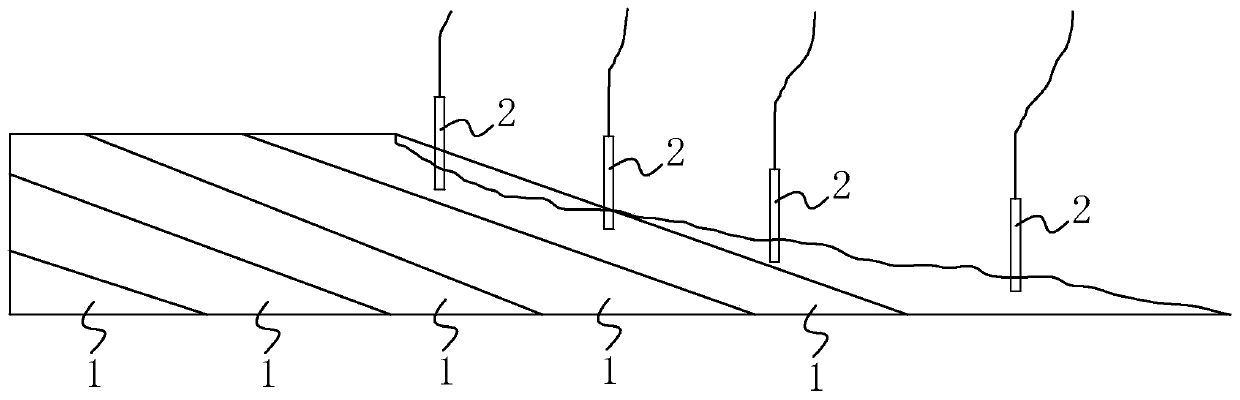

A large-volume concrete mixture and its construction method for pouring walls

A large-volume concrete and construction method technology, which is applied in the processing of building materials, construction, building construction, etc., can solve problems affecting structural safety, affecting structural integrity and safety, and prolonging the construction period, so as to improve overall stability performance, reduce the probability of cracking, and ensure the effect of waterproof quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

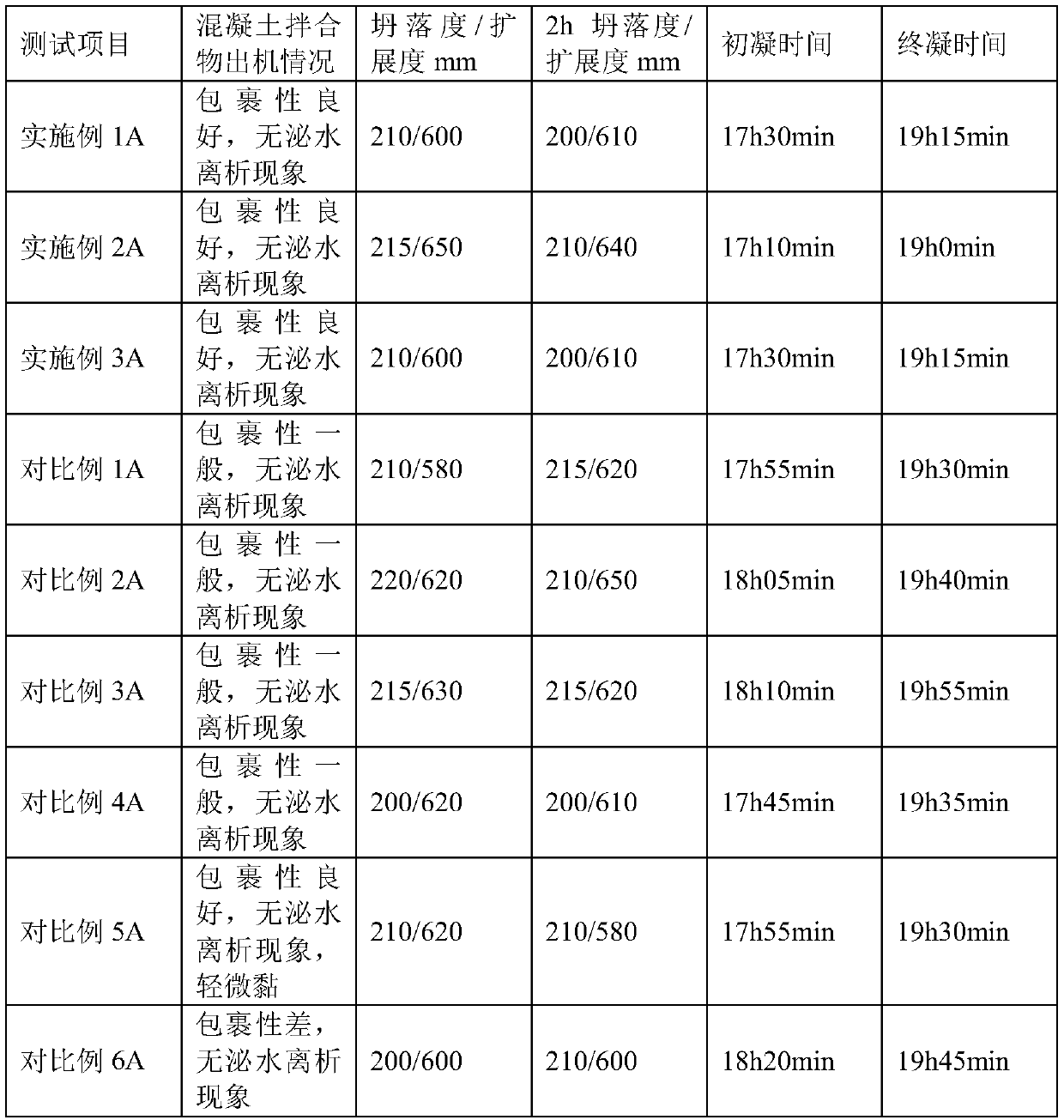

Embodiment 1A

[0034] Embodiment 1A: large volume concrete mixture, with water 165Kg, slag portland cement 214Kg, sand 743Kg, crushed stone 1070Kg, fly ash 103Kg, slag powder 95Kg, polypropylene fiber 0.9Kg, admixture 4.94Kg (JH -GHL polycarboxylate superplasticizer 2.08Kg, JH-III type concrete mortar waterproofing agent 1.56Kg, UEA-H type concrete expansion agent 1.04Kg, basic aluminum acetate 0.104Kg and δ-alumina 0.156Kg), put into the mixer Stir for 10 seconds to obtain a bulky concrete mix.

Embodiment 2A

[0035] Embodiment 2A: large-volume concrete mixture, with water 165Kg, slag portland cement 214Kg, sand 743Kg, gravel 1070Kg, fly ash 103Kg, mineral powder 95Kg, polypropylene fiber 0.9Kg, admixture 4.94Kg (JH -GHL polycarboxylate superplasticizer 2.08Kg, JH-III type concrete mortar waterproofing agent 1.56Kg, UEA-H type concrete expansion agent 1.04Kg, basic aluminum acetate 0.104Kg and δ-alumina 0.156Kg), put into the mixer Mix for 15 seconds to obtain a bulky concrete mix.

Embodiment 3A

[0036]Embodiment 3A: large-volume concrete mixture, with water 165Kg, slag portland cement 214Kg, sand 743Kg, crushed stone 1070Kg, fly ash 103Kg, mineral powder 95Kg, polypropylene fiber 0.9Kg, admixture 4.94Kg (JH -GHL polycarboxylate superplasticizer 2.08Kg, JH-III type concrete mortar waterproofing agent 1.56Kg, UEA-H type concrete expansion agent 1.04Kg, basic aluminum acetate 0.104Kg and δ-alumina 0.156Kg), put into the mixer Stir for 20 seconds to obtain a bulky concrete mix.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com