3D printing silica gel and printing method thereof

A 3D printing and silica gel technology, applied in the field of 3D printing, can solve problems such as clogged nozzles, achieve printing accuracy, improve appearance, and controllable fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

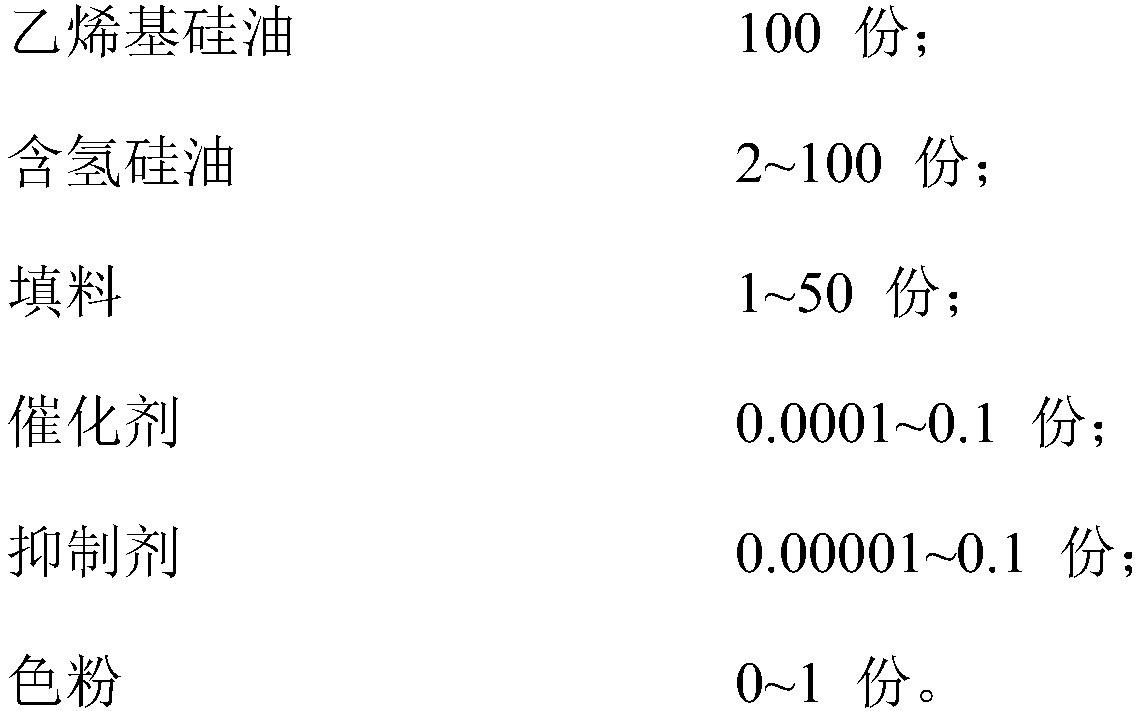

Method used

Image

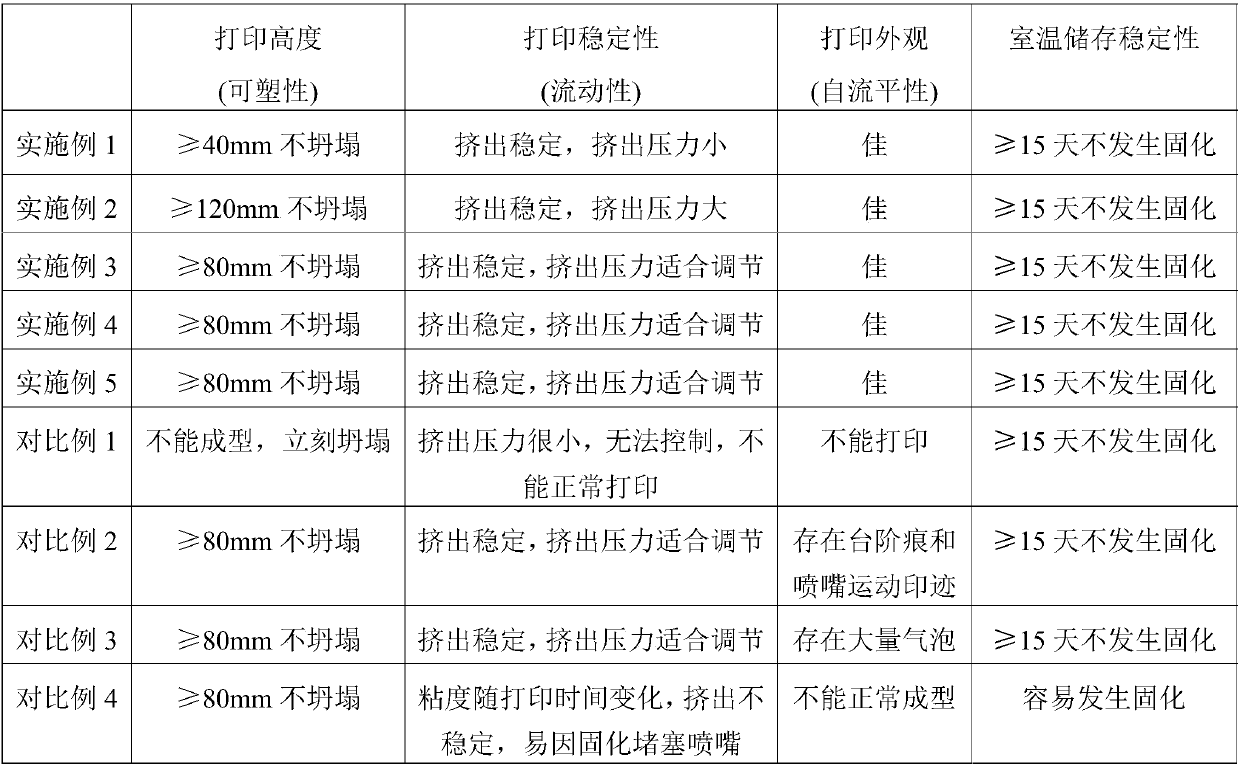

Examples

Embodiment 1

[0027] Step 1: According to methyl vinyl silicone oil (viscosity of 10W mpa s) 100Kg, methyl polyhydrogen silicone oil (viscosity of 5mpa s) 2Kg, hydrophilic calcium carbonate 1Kg, chloroplatinic acid divinyltetramethyl di Siloxane 0.0001Kg, S-containing organic matter 0.00001Kg Weigh the raw materials of each component, mix each component mechanically, and defoam in a vacuum of -0.07MPa;

[0028] Step 2: Load the 3D printing silica gel that has undergone vacuum defoaming into the printing cylinder, and perform defoaming in a vacuum of -0.07MPa;

[0029] Step 3: Install the piston in the printing barrel, and perform defoaming in a vacuum of -0.07MPa, and age for 0.5h after defoaming;

[0030] Step 4: Install the printing cylinder with the piston on the 3D printer, and input the 3D graphics into the 3D printer for printing after slicing. The inner diameter of the nozzle is 0.1mm, and the printing pressure is 0.1MPa;

[0031] Step 5: After the printing is completed, heat-cure t...

Embodiment 2

[0033] Step 1: According to methyl phenyl vinyl silicone oil (viscosity of 50mpa s) 100Kg, terminal hydrogen-containing silicone oil (viscosity of 200mpa s) 100Kg, MQ resin 50Kg, chloroplatinic acid-diethyl phthalate 0.1 Kg, 0.1Kg of ionic compound containing Sn, 1 part of toner Weigh the raw materials of each component, mix each component mechanically, and defoam in a vacuum of -0.08MPa;

[0034] Step 2: Load the 3D printing silica gel that has undergone vacuum defoaming into the printing cylinder, and perform defoaming in a vacuum of -0.08MPa;

[0035] Step 3: Install the piston in the printing barrel, and defoam in a vacuum of -0.08MPa, and age for 72 hours after defoaming;

[0036] Step 4: Install the printing cylinder with the piston on the 3D printer, and input the 3D graphics into the 3D printer for printing after slicing. The inner diameter of the nozzle is 3mm, and the printing pressure is 0.6MPa;

[0037] Step 5: After the printing is completed, heat-cure the printe...

Embodiment 3

[0039] Step 1: According to methyl vinyl silicone oil (viscosity of 5000mpa s) 100Kg, methyl hydrogen-containing silicone oil 4Kg (viscosity of 50mpa s), lipophilic fumed silica 7.5Kg, chloroplatinic acid 0.0015Kg, ethynyl ring Hexanol 0.0008Kg Weigh the raw materials of each component, mix each component mechanically, and defoam in a vacuum of -0.09MPa;

[0040] Step 2: Load the 3D printing silica gel that has undergone vacuum defoaming into the printing cylinder, and perform defoaming in a vacuum of -0.09MPa;

[0041] Step 3: Install the piston in the printing barrel, and perform defoaming in a vacuum of -0.09MPa, and age for 48 hours after defoaming;

[0042] Step 4: Install the printing cylinder with the piston on the direct-writing 3D printer, and input the three-dimensional graphics into the direct-writing 3D printer for printing after slicing. The inner diameter of the nozzle is 0.9mm, and the printing pressure is 0.35MPa;

[0043] Step 5: After the printing is complet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com