Interior wall paint for children and production method

A technology for interior wall coatings and production methods, applied in fire-resistant coatings, antifouling/underwater coatings, coatings, etc., can solve problems such as being unsuitable for children, poor scrub resistance, and poor scrub resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

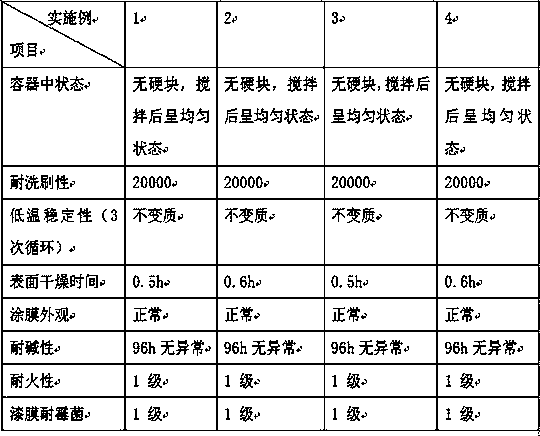

Examples

Embodiment 1

[0083] The production method of children's interior wall paint comprises the following raw materials in parts by weight: 40 parts of polyurethane, 5 parts of emulsion, 10 parts of silk powder, 10 parts of kapok fiber, 2 parts of composite coupling agent, 20 parts of tourmaline, 20 parts of water, 2 parts of edible lemon yellow pigment, 3 parts of white carbon black, 1 part of leveling agent, 2 parts of defoamer,

[0084] The production process of children's interior wall paint includes the following steps:

[0085] (1) Add the formula amount of water, kapok fiber, pigment, white carbon black, leveling agent, 1 / 2 defoamer in turn into the mixer, stir evenly, at a speed of 300 rpm, stir for 15 minutes, and form colloidal solution;

[0086] (2) Grind the solution obtained in step (1) through a sander until the particle size is within 30 microns, and then put the solution back into the mixer;

[0087] (3) Mix silk powder and polyurethane according to the weight ratio of the form...

Embodiment 2

[0098] The production method of children's interior wall paint comprises the following raw materials in parts by weight: 45 parts of polyurethane, 10 parts of emulsion, 15 parts of silk powder, 15 parts of kapok fiber, 3 parts of composite coupling agent, 25 parts of tourmaline, 25 parts of water, 3 parts of edible orange pigment, 4 parts of white carbon black, 2 parts of leveling agent, 3 parts of defoamer,

[0099] The production process of children's interior wall paint includes the following steps:

[0100] (1) Add the formula amount of water, kapok fiber, pigment, white carbon black, leveling agent, 1 / 2 defoamer in turn into the mixer, stir evenly, at a speed of 300 rpm, stir for 20 minutes, and form colloidal solution;

[0101] (2) Grind the solution obtained in step (1) through a sander until the particle size is within 30 microns, and then put the solution back into the mixer;

[0102] (3) Mix silk powder and polyurethane according to the weight ratio of the formula,...

Embodiment 3

[0113] The production method of children's interior wall paint comprises the following raw materials in parts by weight: 50 parts of polyurethane, 15 parts of emulsion, 20 parts of silk powder, 20 parts of kapok fiber, 4 parts of composite coupling agent, 30 parts of tourmaline, 25 parts of water, 5 parts of edible carmine pigment, 5 parts of white carbon black, 3 parts of leveling agent, 3 parts of defoamer,

[0114] The production process of children's interior wall paint includes the following steps:

[0115] (1) Add the formula amount of water, kapok fiber, pigment, white carbon black, leveling agent, 1 / 2 defoamer in turn into the mixer, stir evenly, at a speed of 300 rpm, stir for 20 minutes, and form colloidal solution;

[0116] (2) Grind the solution obtained in step (1) through a sander until the particle size is within 30 microns, and then put the solution back into the mixer;

[0117] (3) Mix silk powder and polyurethane according to the weight ratio of the formula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com