Agent for purifying gas wells and draining and preparation method thereof

A chemical and liquid drainage technology, which is applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve problems such as insufficient efficiency, increased wellbore blockage, and increased viscosity of produced fluid, etc., to achieve Purification adapts to a wide range, improves purification efficiency, and accelerates the effect of purification speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] This embodiment also provides a method for preparing the above-mentioned medicament for gas well purification and liquid drainage, which includes:

[0027] Mix hydrocarbyl methylamino carboxylic acid with water, heat to 45-55°C, mix with polyoxyethylene ether, perfluoroalkylammonium chloride and 2,5-alkylpyrazine under stirring conditions, and stir at constant temperature After 20 to 40 minutes, mix with ethylene oxide and propylene oxide copolymer, dissolve completely and cool down.

[0028] Further, the mixing process of the materials is carried out under stirring, so that they can be mixed quickly and uniformly in a short time, and the stirring rate is 30-60r / min, or 35-55r / min, or 40-50r / min. / min, or 42~48r / min, or 44~46r / min.

[0029] Further, in the process of mixing the materials, first mix the hydrocarbyl methylamino carboxylic acid with water, heat it to a constant temperature of 45-55°C, mix it with polyoxyethylene ether under the condition of stirring, and ...

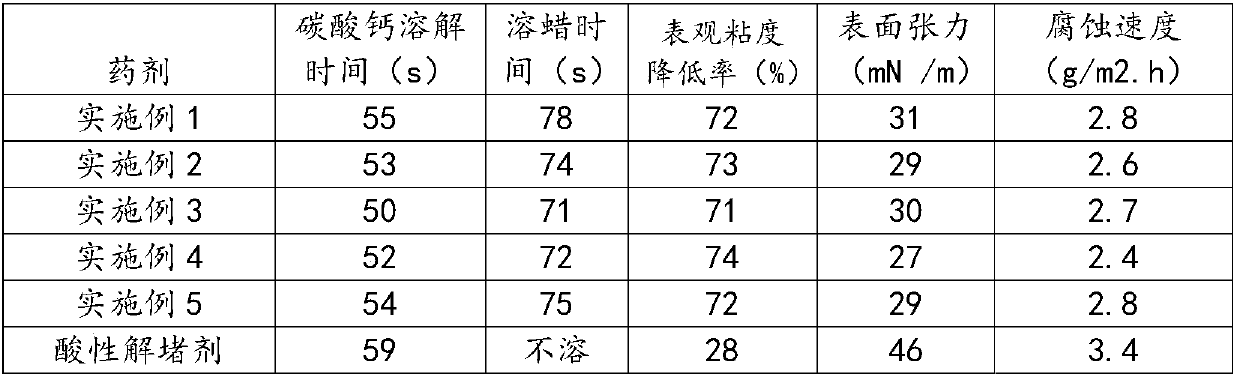

Embodiment 1

[0032] This embodiment provides a medicament for gas well purification and liquid drainage, which includes:

[0033] Hydrocarbyl methylamino carboxylic acid 30Kg, fatty alcohol polyoxyethylene ether 20Kg, ethylene oxide propylene oxide copolymer 5Kg, perfluoroalkylammonium chloride 1Kg, 2,5-alkylpyrazine 0.1Kg.

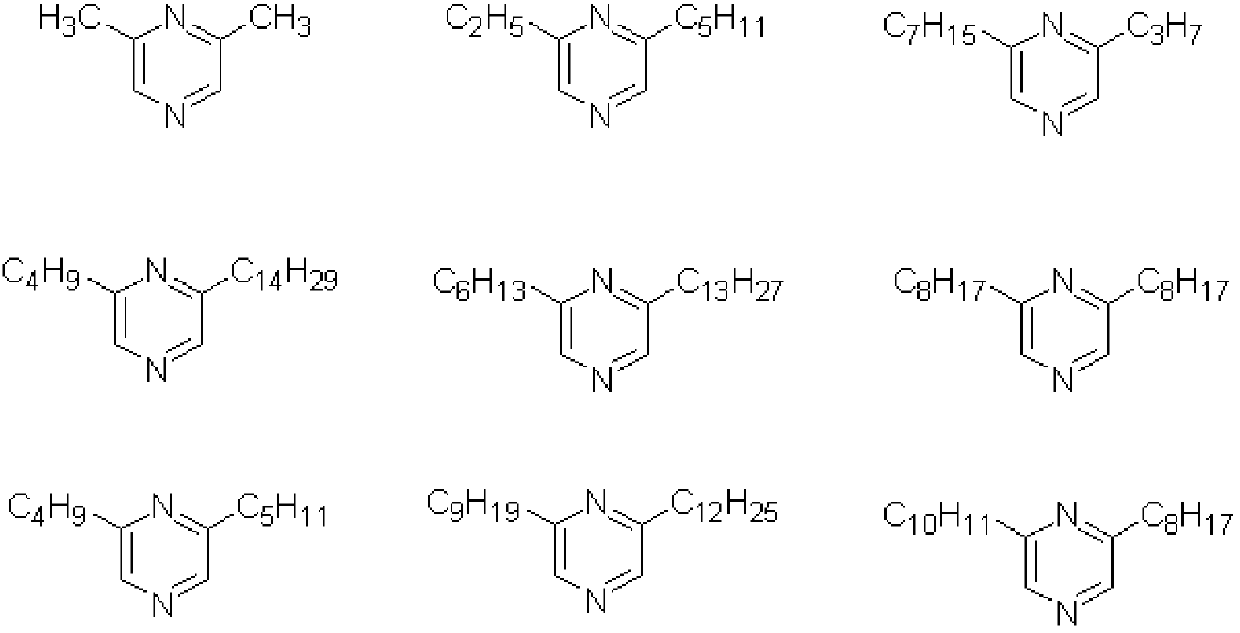

[0034] Among them, the hydrocarbyl methylamino carboxylic acid is C8H17-N(CH3)-COOH; fatty alcohol polyoxyethylene ether, the degree of polymerization is 2; the molecular weight of ethylene oxide propylene oxide copolymer is 2000g / mol; perfluoroalkyl chloride Ammonium chloride is C8H17-NH3+Cl-: 2,5-alkylpyrazine is:

[0035] The preparation method of this medicament comprises:

[0036] Mix hydrocarbyl methylamino carboxylic acid with water, heat to a constant temperature of 45°C, then mix with fatty alcohol polyoxyethylene ether, perfluoroalkylammonium chloride and 2,5-alkylpyrazine under stirring at 60r / min, After stirring at a constant temperature for 25 minutes...

Embodiment 2

[0038] This embodiment provides a medicament for gas well purification and liquid drainage, which includes:

[0039] Hydrocarbyl methylamino carboxylic acid 40Kg, fatty alcohol polyoxyethylene ether 15Kg, ethylene oxide propylene oxide copolymer 15Kg, perfluoroalkylammonium chloride 0.3Kg, 2,5-alkylpyrazine 1.5Kg.

[0040] Among them, hydrocarbyl methylamino carboxylic acid is obtained by mixing CH3-N(CH3)-COOH and C3H7-N(CH3)-COOH according to the mass ratio of 1:1; fatty alcohol polyoxyethylene ether, the degree of polymerization is 5; ethylene oxide The molecular weight of the alkylene oxide copolymer is 200g / mol; the perfluoroalkylammonium chloride is (C14H29)2-NH2+Cl-: 2,5-alkylpyrazine is:

[0041] The preparation method of this medicament comprises:

[0042] Mix hydrocarbyl methylamino carboxylic acid with water, heat to a constant temperature of 55°C, then mix with fatty alcohol polyoxyethylene ether, perfluoroalkylammonium chloride and 2,5-alkylpyrazine under stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com