Oxygen-enriched combustion tail gas treatment system adopting low-temperature condensation method

A technology of oxygen-enriched combustion and tail gas treatment, which is applied in gas treatment, sublimation, solidification, etc., can solve the problems of inability to realize heat exchange, and achieve the effect of simple structure and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

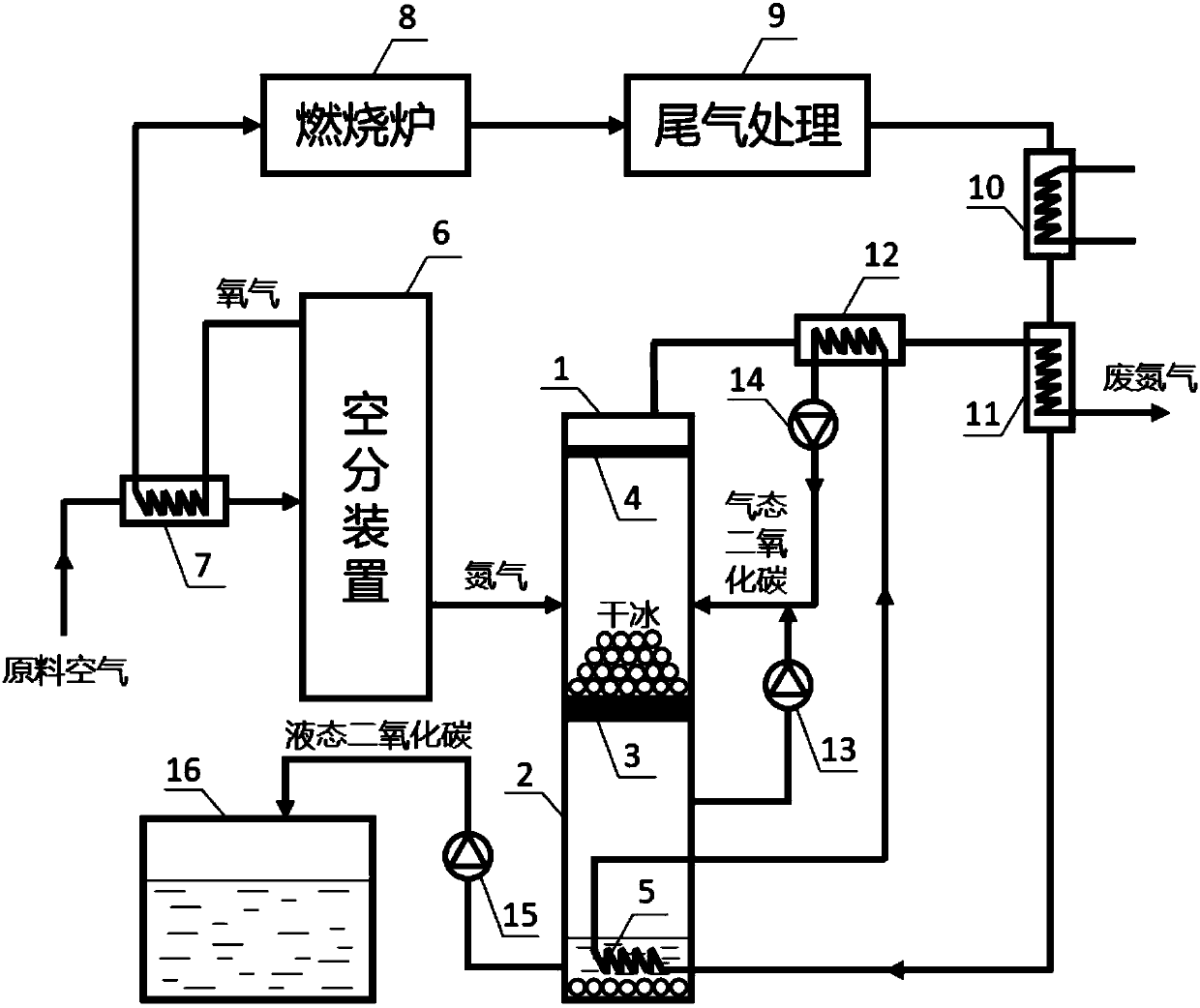

[0027] see figure 1 In this embodiment, the oxy-fuel combustion tail gas treatment system adopting the low-temperature desublimation method includes an oxy-fuel combustion device, a carbon dioxide capture device and an air separation device 6 .

[0028] The oxygen-enriched combustion device includes a combustion furnace 8 and a tail gas processor 9. The combustion furnace 8 can carry out oxygen-enriched combustion, and the tail gas produced contains high-concentration carbon dioxide gas. The tail gas processor 9 has functions such as filtering, adsorption and drying. 8 The exhausted tail gas is dried and purified to obtain carbon dioxide raw material gas that can be used for capture.

[0029] The carbon dioxide capture device includes a desublimation chamber 1 , a liquefaction chamber 2 and a liquid storage tank 16 . The desublimation chamber 1 and the liquefaction chamber 2 are set in the same chamber, separated by a movable sealing plate 3, the liquefaction chamber 2 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com