Production system for ship outfitting pieces

A production system and outfitting technology, which is applied in the field of ship parts processing, can solve the problems of unutilized useful resources, high energy consumption, and environmental protection, and achieve the effects of stable base structure, high surface friction coefficient, and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

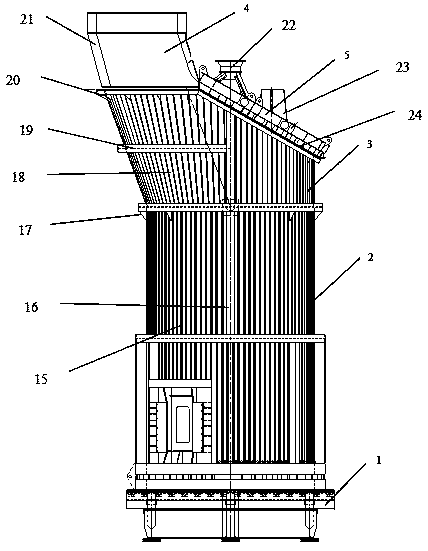

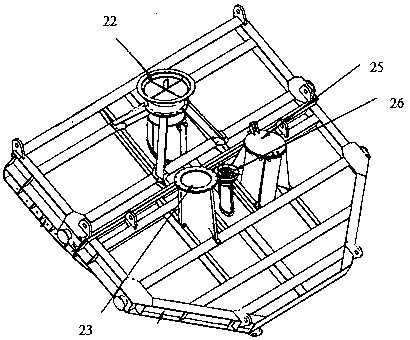

[0033] like Figure 1-Figure 5 A production system for ship outfitting is shown, including a furnace base 1, a lower cylindrical furnace 2, an intermediate conical furnace 3, an upper transition furnace 4, and a furnace top 5; wherein the furnace base 1 and the lower cylindrical furnace 2 belongs to the nested connection; the lower cylindrical furnace 2 is welded together with the middle conical furnace 3; the middle conical furnace 3 and the furnace roof 5 are bolted; It is a snug connection.

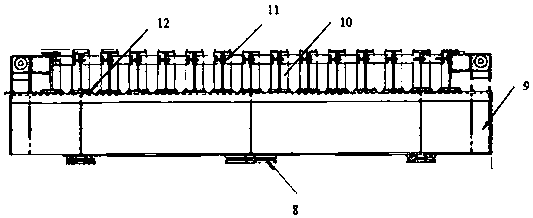

[0034] Furnace base 1 includes several I-shaped steels, T-shaped support plates 8 arranged at the lower parts of several I-shaped steels, several furnace body stops 13 fixed on the upper ends of I-shaped steels, positioning stops 12 and adjusting bolts 11; several I-shaped steels ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com