Rotary and rapid elastic releaser and design method thereof

A releaser and elastic technology, which is applied in the field of fast elastic releaser for transmission wire rotation, can solve problems such as tower tilt, threat to safe and stable operation of power grid, and increase in wire sag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

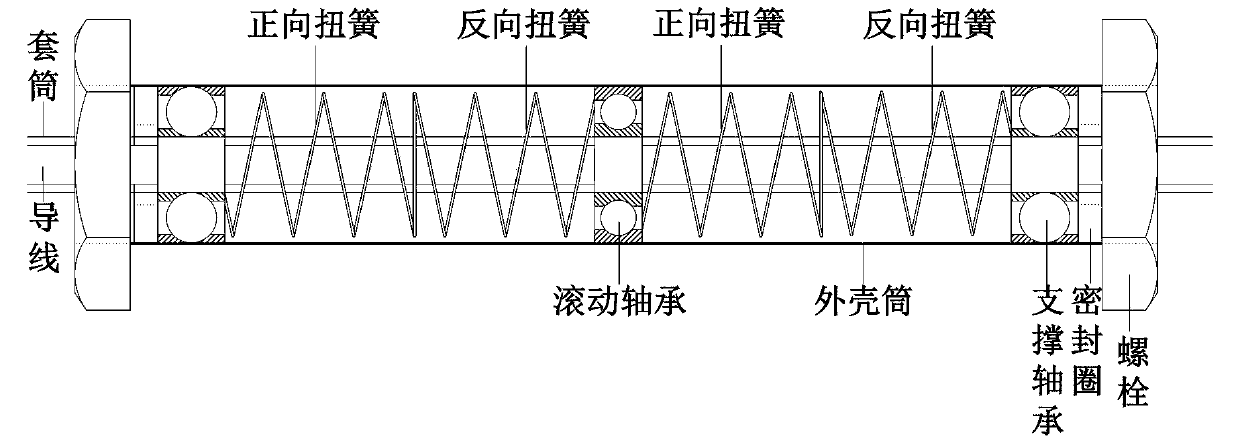

[0040] Measure and calculate the rotation amplitude and frequency of a region by the MEMS inertial measurement system of the wire movement, and then design the parameters of the elastic release device according to the amplitude-frequency characteristics of the motion, design the structure of the rotation quick release device, manufacture and test the actual object, and the following description is combined with the accompanying drawings The concrete implementation of the present invention.

[0041] The wire motion measurement system is mainly composed of wire motion MEMS inertial measurement system, Zigbee wireless transmission, power supply and monitoring center.

[0042] Due to the rotation of the wire, the angular velocity data collected by the MEMS inertial measurement system has the characteristics of high dimensionality, complexity, dynamics, and high noise. value deviation.

[0043] The measurement of the rotation range of the wire is not measured by calculating the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com