Temperature-control-based anti-freezing material and preparation method and application thereof

A technology of antifreeze material and temperature sensitive material, which is applied in the field of antifreeze and deicing of road pavement, can solve the problems that the release of anti-icing components cannot be well controlled, the effective release of anti-icing components is not sufficient, and the deicing effect is not obvious. To achieve the effect of ensuring safety and smooth flow, rapid antifreeze response and reducing invalid release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

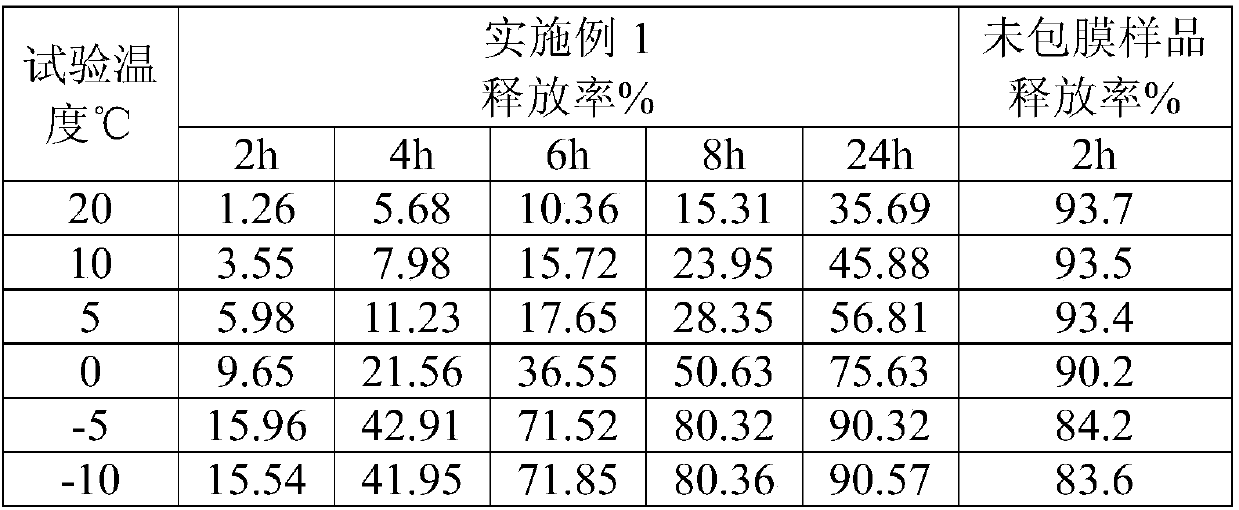

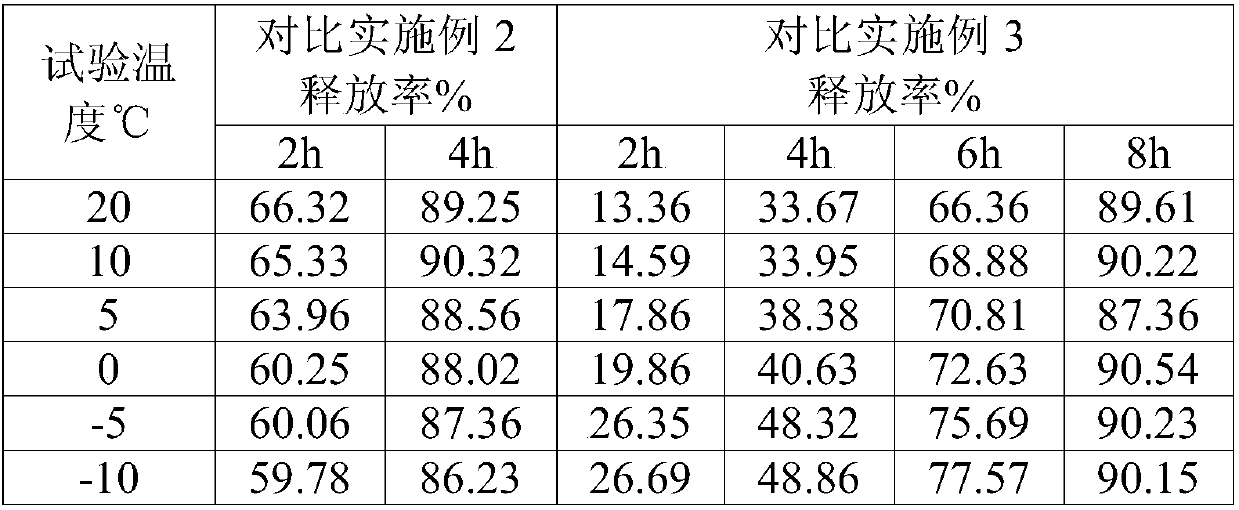

Examples

Embodiment 1

[0023] Weigh ice suppression materials, calcium chloride 50g, magnesium chloride 14g;

[0024] 1 g of rust inhibitor, including 0.2 g of zinc dihydrogen phosphate, 0.25 g of sodium tungstate, 0.25 g of thiourea, 0.1 g of tetraethylenepentamine, and 0.2 g of sodium dodecylbenzenesulfonate.

[0025] 15g of hydrophobic materials, including 3g of polyether diol, 3g of hexamethylene diisocyanate, 3g of hydroxypropyl methylcellulose, 3g of talcum powder, and 3g of calcium carbonate powder.

[0026] 20g of temperature-sensitive materials, including 10g of N-isopropylacrylamide, 2g of N,N'-methylenebisacrylamide, and 8g of tetramethylethylenediamine.

[0027] The preparation method steps are as follows:

[0028] (1) Mix the anti-icing material and the rust inhibitor after crushing, and then granulate to obtain core material particles;

[0029] (2) Evenly stir and heat the core material particles obtained in step (1) with talcum powder, hydroxypropyl methylcellulose and calcium carbo...

Embodiment 2

[0032] Weigh ice suppression materials, calcium chloride 59.5g, magnesium chloride 10g;

[0033] 0.5g of rust inhibitor, including 0.1g of zinc dihydrogen phosphate, 0.15g of sodium tungstate, 0.1g of thiourea, 0.05g of tetraethylenepentamine, and 0.1g of sodium dodecylbenzenesulfonate.

[0034] 15g of hydrophobic materials, including 5g of polyether diol, 3g of hexamethylene diisocyanate, 2g of hydroxypropyl methylcellulose, 3g of talcum powder, and 2g of calcium carbonate powder.

[0035] 15g of temperature-sensitive materials, including 8g of N-isopropylacrylamide, 2g of N,N'-methylenebisacrylamide, and 5g of tetramethylethylenediamine.

[0036] The preparation method is shown in Example 1.

Embodiment 3

[0038] Weigh the ice suppression material, calcium chloride 64.2g;

[0039] 0.8g of rust inhibitor, including 0.15g of zinc dihydrogen phosphate, 0.25g of sodium tungstate, 0.2g of thiourea, 0.1g of tetraethylenepentamine, and 0.1g of sodium dodecylbenzenesulfonate.

[0040] 15g of hydrophobic materials, including 5g of polyether diol, 3g of hexamethylene diisocyanate, 2g of hydroxypropyl methylcellulose, 3g of talcum powder, and 2g of calcium carbonate powder.

[0041] 20g of temperature-sensitive materials, including 12g of N-isopropylacrylamide, 3g of N,N'-methylenebisacrylamide, and 5g of tetramethylethylenediamine.

[0042] The preparation method is shown in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com