Water in water colorful paint for building outer wall and preparation method thereof

A technology for colorful coatings and building exterior walls, applied in the field of building materials, can solve the problems of large color errors, easy falling off, and difficult construction of colored particles, and achieve the effects of stable quality between batches, wide application prospects, and wide application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

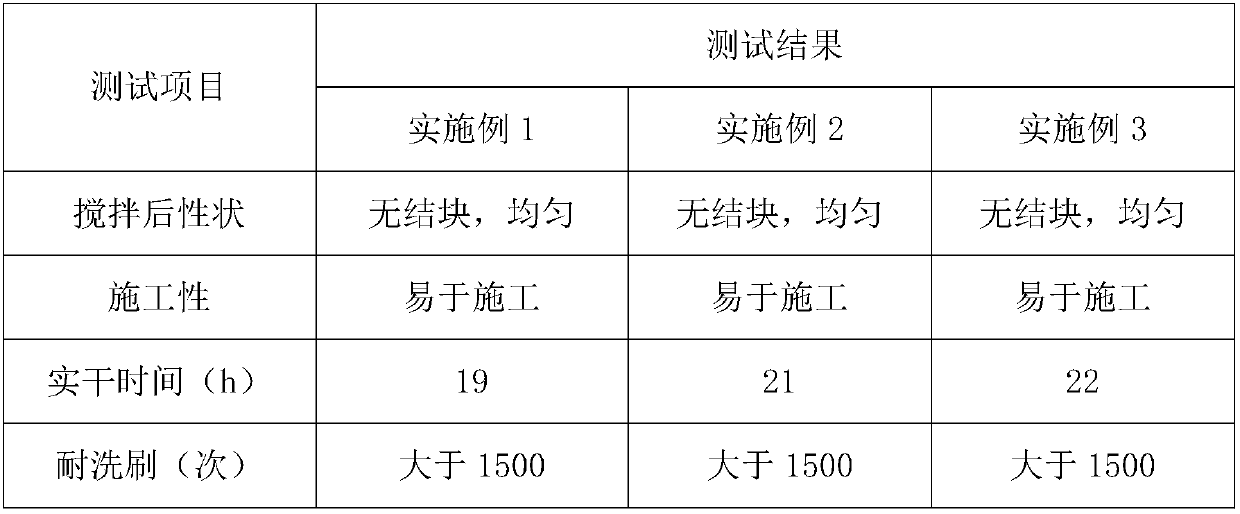

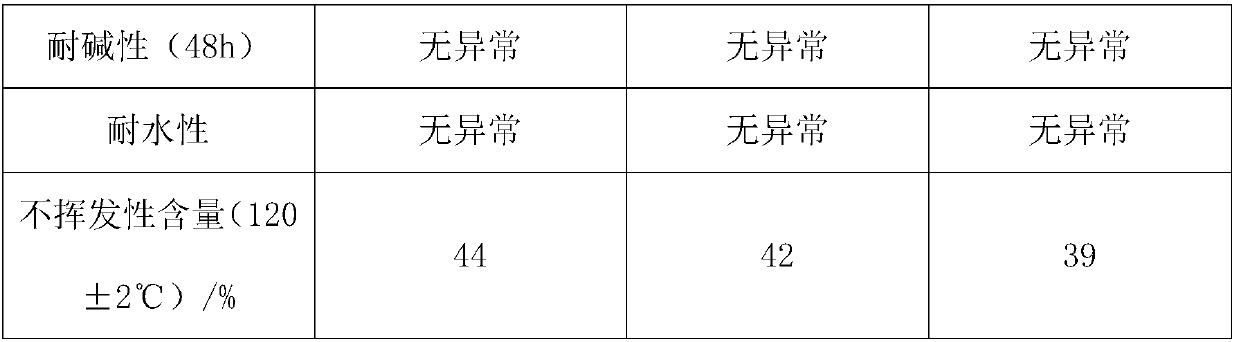

Examples

Embodiment 1

[0046] The optimal dosage ratio and selection of raw materials for water-in-water colorful paints are:

[0047] 10 parts of protective rubber powder;

[0048] 40 parts of vinyl chloride-vinylidene chloride copolymer emulsion;

[0049] 15 parts of acrylate quaternary copolymerization emulsion;

[0050] 18 parts of water-based fluorocarbon emulsion;

[0051] 25 parts of titanium dioxide;

[0052] 30 parts of white carbon black;

[0053] 1400 parts of water;

[0054] 10 parts of ethylene-vinyl alcohol copolymer resin;

[0055] 8 parts of sodium glycinate;

[0056] 6 parts of sodium cysteine;

[0057] 5 parts of sodium chloride;

[0058] 30 parts of kaolin;

[0059] 6 parts of water-based paint thickener;

[0060] Appropriate amount of water-based paint.

[0061] The thickener is HPC.

[0062] The water-based pigments include iron oxide red, sunfast yellow, and phthalocyanine blue.

[0063] The preparation method of described coating is:

[0064] (1) Dissolve the pro...

Embodiment 2

[0069] 6 parts of protective rubber powder;

[0070] 30 parts of vinyl chloride-vinylidene chloride copolymer emulsion;

[0071] 10 parts of acrylate quaternary copolymerization emulsion;

[0072] 15 parts of water-based fluorocarbon emulsion;

[0073] 20 parts of titanium dioxide;

[0074] 25 parts of white carbon black;

[0075] 1300 parts of water;

[0076] 5 parts of ethylene-vinyl alcohol copolymer resin;

[0077] 5 parts of sodium glycinate;

[0078] 3 parts of sodium cysteine;

[0079] 2 parts of sodium chloride;

[0080] 20 parts of kaolin;

[0081] 4 parts of water-based paint thickener;

[0082] Appropriate amount of water-based paint.

[0083] The thickener can be non-ionic cellulose, specifically HEC.

[0084] The water-based pigments include iron oxide red, sunfast yellow, and phthalocyanine blue.

[0085] The preparation method of described coating is identical with the preparation method among the embodiment 1, only the stirring time in step (4) is c...

Embodiment 3

[0087] 12 parts of protective rubber powder;

[0088] 50 parts of vinyl chloride-vinylidene chloride copolymer emulsion;

[0089] 20 parts of acrylate quaternary copolymerization emulsion;

[0090] 20 parts of water-based fluorocarbon emulsion;

[0091] 30 parts of titanium dioxide;

[0092] 35 parts of white carbon black;

[0093] 1500 parts of water;

[0094] 15 parts of ethylene-vinyl alcohol copolymer resin;

[0095] Sodium glycinate 10 parts;

[0096] 8 parts of sodium cysteine;

[0097] 7 parts of sodium chloride;

[0098] 40 parts of kaolin;

[0099] 8 parts of water-based paint thickener;

[0100] Appropriate amount of water-based paint.

[0101] The thickener can be non-ionic cellulose, specifically HPC.

[0102] The water-based pigments include iron oxide red, sunfast yellow, and phthalocyanine blue.

[0103] The preparation method of the coating is the same as that in Example 1, only the stirring time in step (4) is changed to 8 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com