Annealing system waste heat recovery device

A waste heat recovery device and annealing technology, used in waste heat treatment, heat treatment furnaces, heat treatment equipment, etc., can solve the problems of uneven temperature distribution, low temperature of preheated workpieces, and low utilization rate of heat energy, and achieve high utilization rate of waste heat. The effect of uniform and high utilization of waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

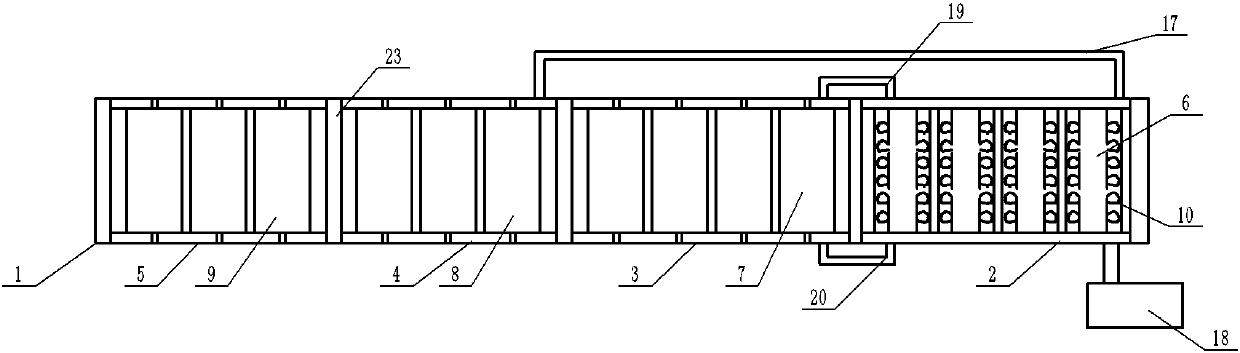

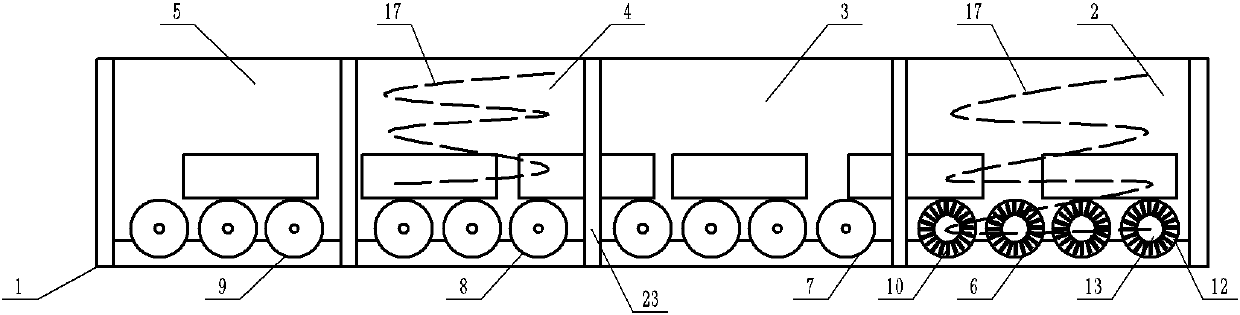

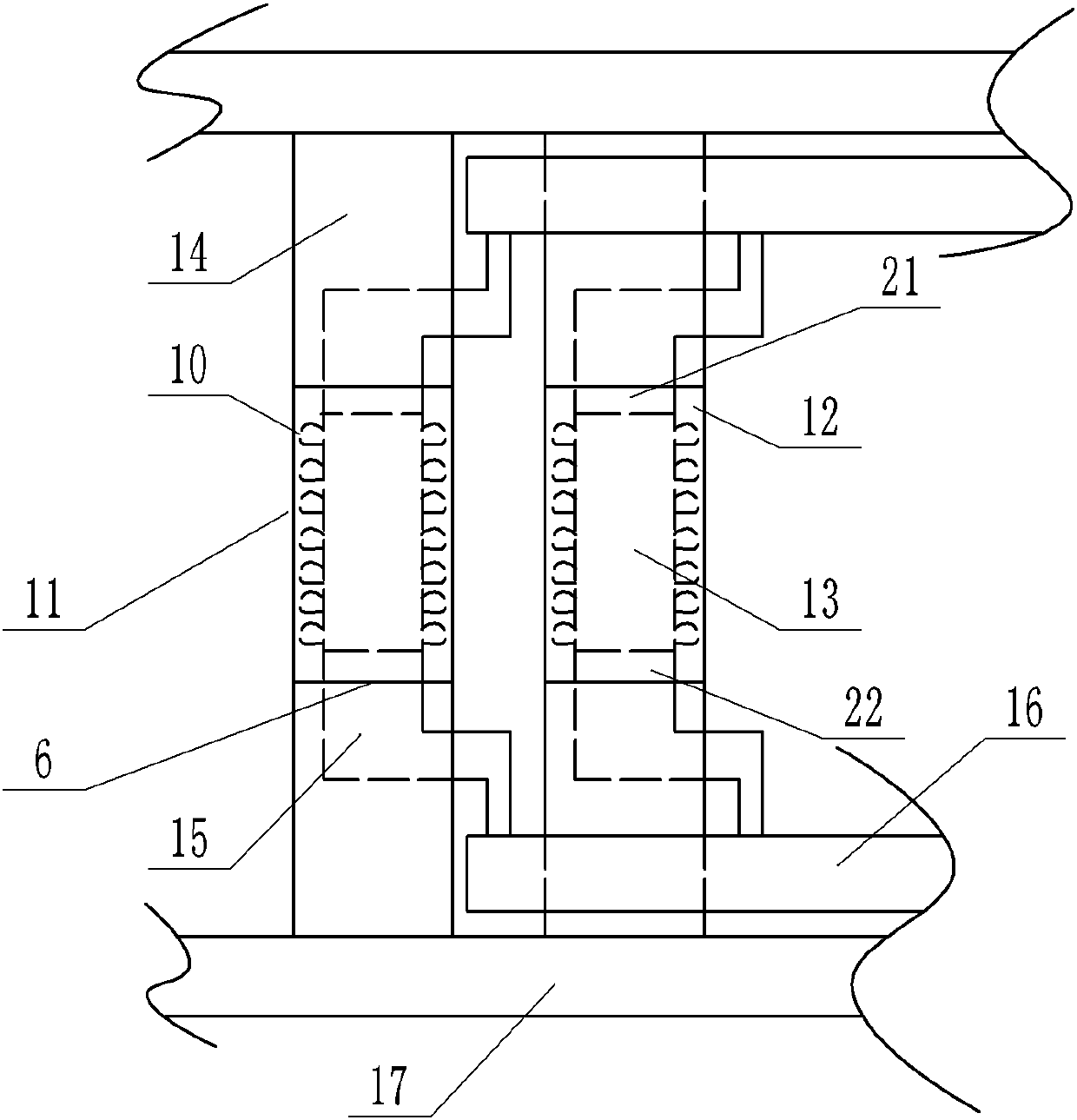

[0020] The present invention will be described in further detail below through specific embodiments,

[0021] The reference numerals in the accompanying drawings of the description include: annealing furnace 1, heating section 2, isothermal section 3, slow cooling section 4, normal temperature cooling section 5, first traveling roller 6, second traveling roller 7, third traveling roller 8, Fourth walking roller 9, rotating blade 10, waste heat utilization unit 11, water layer 12, wind layer 13, water pipe 14, air pipe 15, air main pipe 16, water main pipe 17, water pump 18, hot air pipe 19, hot air outlet Pipe 20, air inlet vane 21, air outlet vane 22, insulation door 23.

[0022] Embodiment The waste heat recovery device of the annealing system is basically as attached figure 1 with figure 2 As shown, the waste heat recovery device of the annealing system is set in the annealing furnace 1, including the annealing furnace 1, and the annealing furnace 1 includes a heating se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com