Automatic transmission

A technology of automatic transmission and box owner, applied in the direction of vehicle transmission, transmission components, transmission devices, etc., can solve the problems of short maintenance cycle, easy driver fatigue, and imprecise coordination of various components, so as to achieve low maintenance and use costs. , The effect of low engine compartment space and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

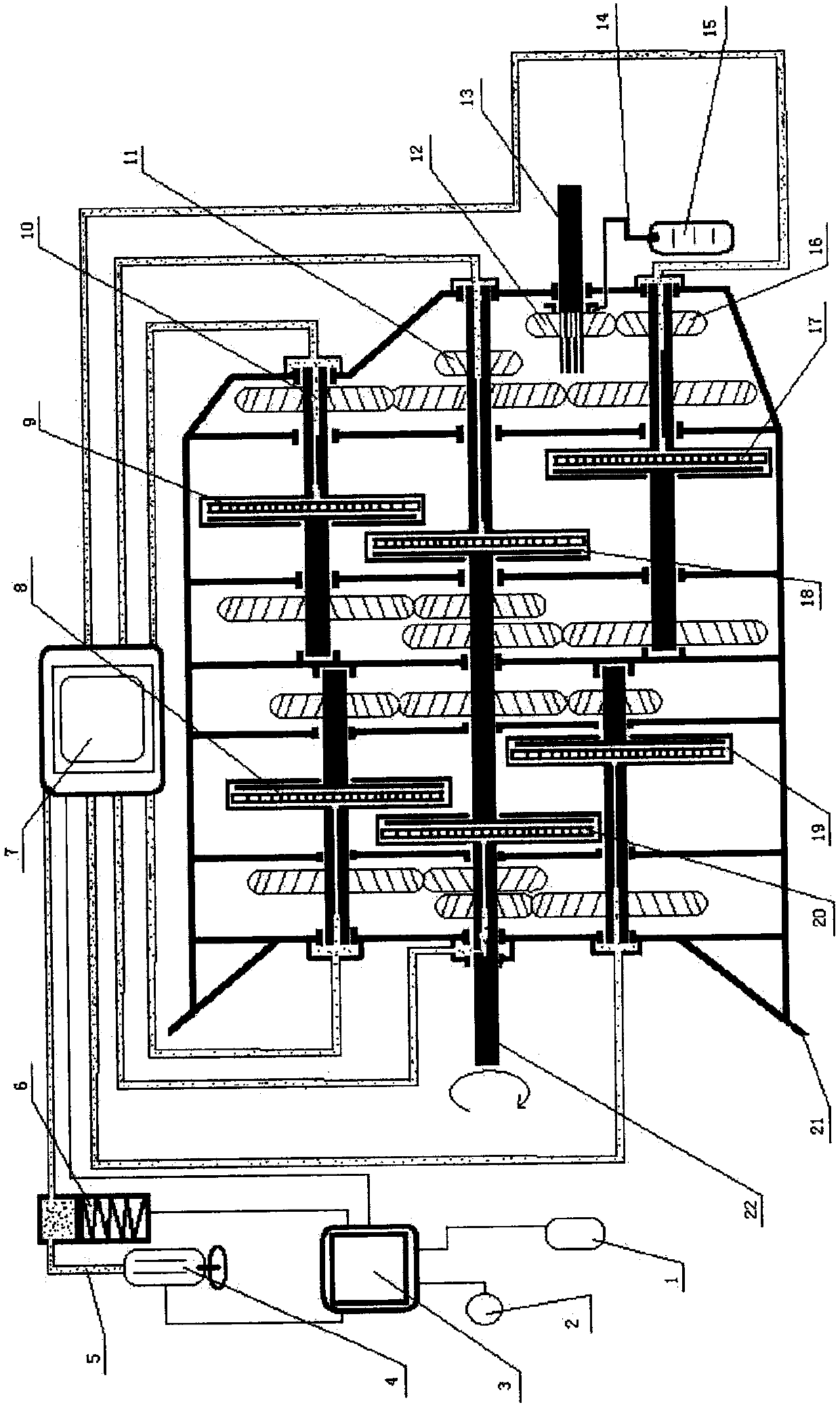

[0030] Depend on figure 1 It can be seen that the present invention includes a casing, a main controller of a gearbox, an electronically controlled hydraulic distributor, and a clutch. The main controller of the gearbox is connected to the electronically controlled hydraulic distributor through a hydraulic pump. The device is connected with the hollow shaft oil channel in the clutch through the hydraulic pipeline, and is used to supply hydraulic oil to the clutch; the power input shaft and the power output shaft are respectively arranged on both sides of the housing, and the other end of the power input shaft is connected with the engine. Used for power transmission of the engine, the power output shaft is connected with the differential case outside the casing.

[0031] The clutches are divided into high-speed clutches, medium-speed clutches, low-speed clutches, first clutches, second clutches and third clutches; the combination of the first clutch and the low-speed clutch is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com