Full-automatic feeding system for liquid fodder feeding in pig farm

A liquid material and fully automatic technology, applied in animal feeding devices, applications, animal drinking water devices, etc., can solve problems such as pollution, increased operating costs, and health hazards of pigs, and achieve the effect of improving feeding efficiency and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

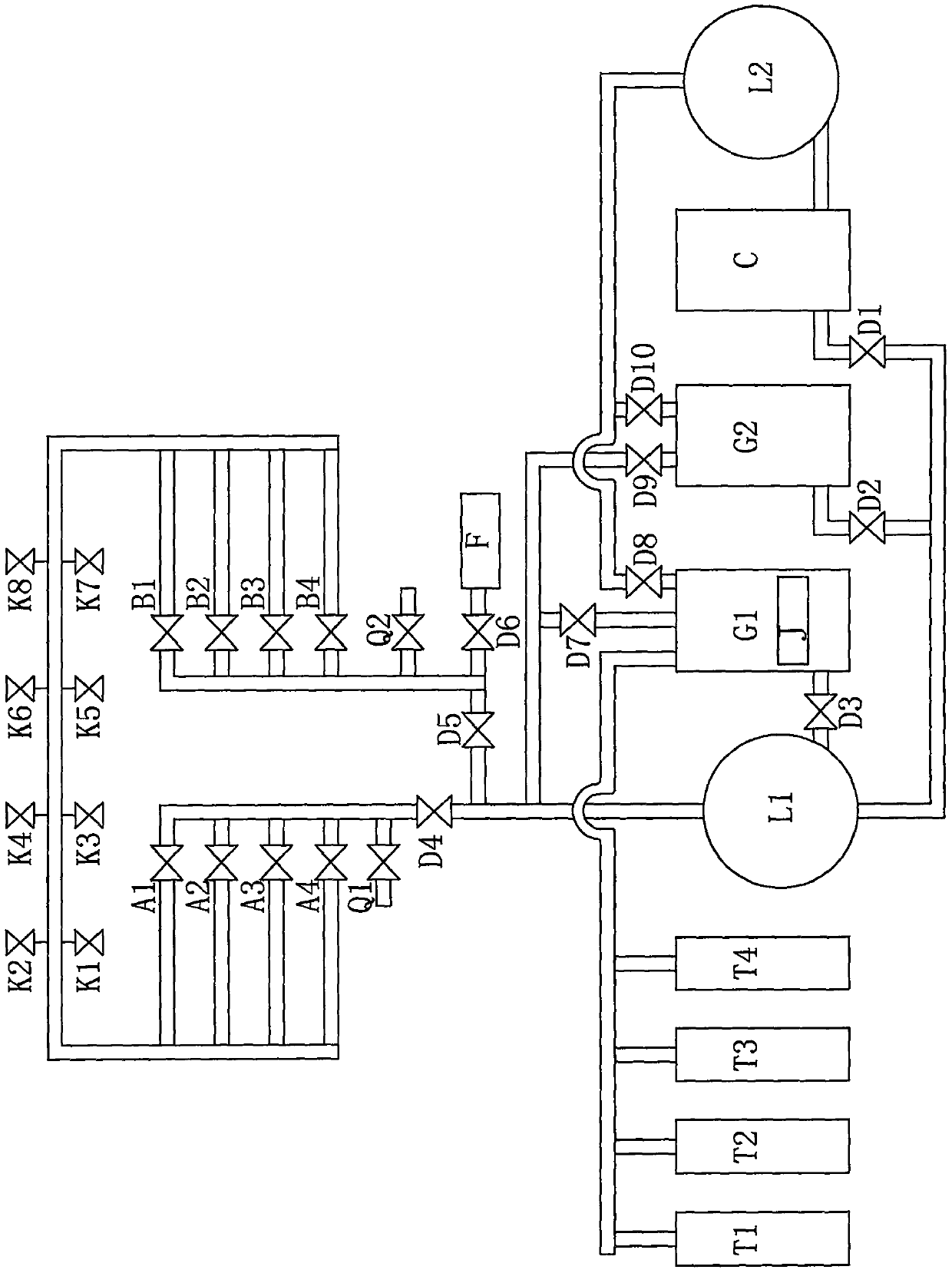

[0016] refer to figure 1 , the fully automatic feeding system for liquid feed feeding in pig farms described in this embodiment includes: mixing tank G1, storage tank G2, water storage container C, cleaning water pump L2, feeding water pump L1, dry material storage Towers T1-T4, high-pressure fan F, several feeding stations, air pumps, several pneumatic valves and PLC control devices.

[0017] The mixing tank G1, the storage tank G2 and the water storage container C are all provided with a weighing device, and the mixing tank G1 and the storage tank G2 are respectively provided with a stirring device driven by a stirring motor; each dry material storage tower is A material conveying motor is provided, and the discharge port of each dry material storage tower is connected to the feed port of the mixing tank G1 through a dry material pipeline; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com