Method for preparing liquid fermented feed for fattening local hybrid pigs

A technology of liquid fermentation and manufacturing method, which is applied in the direction of animal feed, animal feed, additional food elements, etc., can solve the problems of unfavorable large-scale breeding and high cost of soil pig breeding, so as to reduce the cost of breeding, reduce the cost of feeding, save The effect of food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

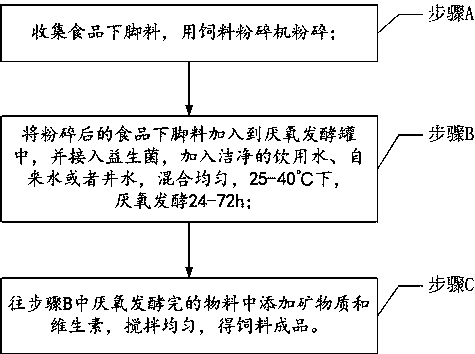

Method used

Image

Examples

Embodiment 1

[0039]Collect biscuit crumbs, bread crumbs, noodle crumbs and other food processing scraps and pineapple peels, grind them into 100 meshes with a feed grinder, add the crushed food scraps to the anaerobic fermentation tank, and insert them according to the weight of the fermentation liquid Calculate 1 million CFU / g of Bacillus subtilis, 500,000 CFU / g of Bacillus licheniformis, and 4000 CFU / g of lactic acid bacteria, add clean tap water to make the ratio of material to liquid 1:4, mix well, and anaerobically ferment for 24 hours at 40°C After the anaerobic fermentation is completed, add the composite trace element minerals and the multivitamin for pigs respectively accounting for 1% of the total mass of the material, stir evenly, and obtain the finished feed product;

[0040] The finished feed is directly fed to soil pigs, with good palatability, high feed digestibility, feed saving, good growth of feeding pigs, and low incidence of disease.

Embodiment 2

[0042] Collect expired rice, expired wheat and other expired grains, crush them into 200 meshes with a feed grinder, add the crushed food waste into the anaerobic fermentation tank, and insert 1 million CFU / gram, Bacillus coagulans 800,000 CFU / gram, saccharomyces 10,000 CFU / gram, add clean well water to make the ratio of material to liquid 2:7, mix evenly, and anaerobically ferment for 48 hours at 30°C; Finally, adding compound trace element minerals and multi vitamins for pigs respectively accounting for 1% of the total mass of the material, stirring evenly, to obtain the finished feed product;

[0043] After the finished feed is mixed with the full-price commercial feed at a ratio of 1:1, it is fed to pigs with poor palatability, high feed digestibility, feed saving, good growth and low incidence of pigs. .

Embodiment 3

[0045] Collect expired packaged foods such as biscuits, expired bread, and bread crumbs, and use a feed mill to crush them into 150 meshes. Add the crushed food waste and 15% bran to the anaerobic fermentation tank, and connect them according to the fermentation process. Yeast 5000CFU / g and lactic acid bacteria 5000CFU / g calculated by liquid weight, add drinking water to make the ratio of material to liquid 1:3, mix evenly, and anaerobically ferment for 36h at 25°C; after anaerobic fermentation, add 1% of the total mass of pigs with compound trace element minerals and pigs with multivitamins, stirred evenly, to obtain finished feed;

[0046] After the finished feed is mixed with the full-price commercial feed at a ratio of 2:1, it is fed to pigs with poor palatability, high feed digestibility, feed saving, good growth and low incidence of pigs. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com