Device for removal of organic waste gas with suspended state photocatalyst and treatment method thereof

A technology of organic waste gas and photocatalyst, which is applied in gas treatment, chemical instruments and methods, separation methods, etc., can solve the problems of high economic investment and complicated methods, and achieve the effects of increasing the contact area, simple device structure, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

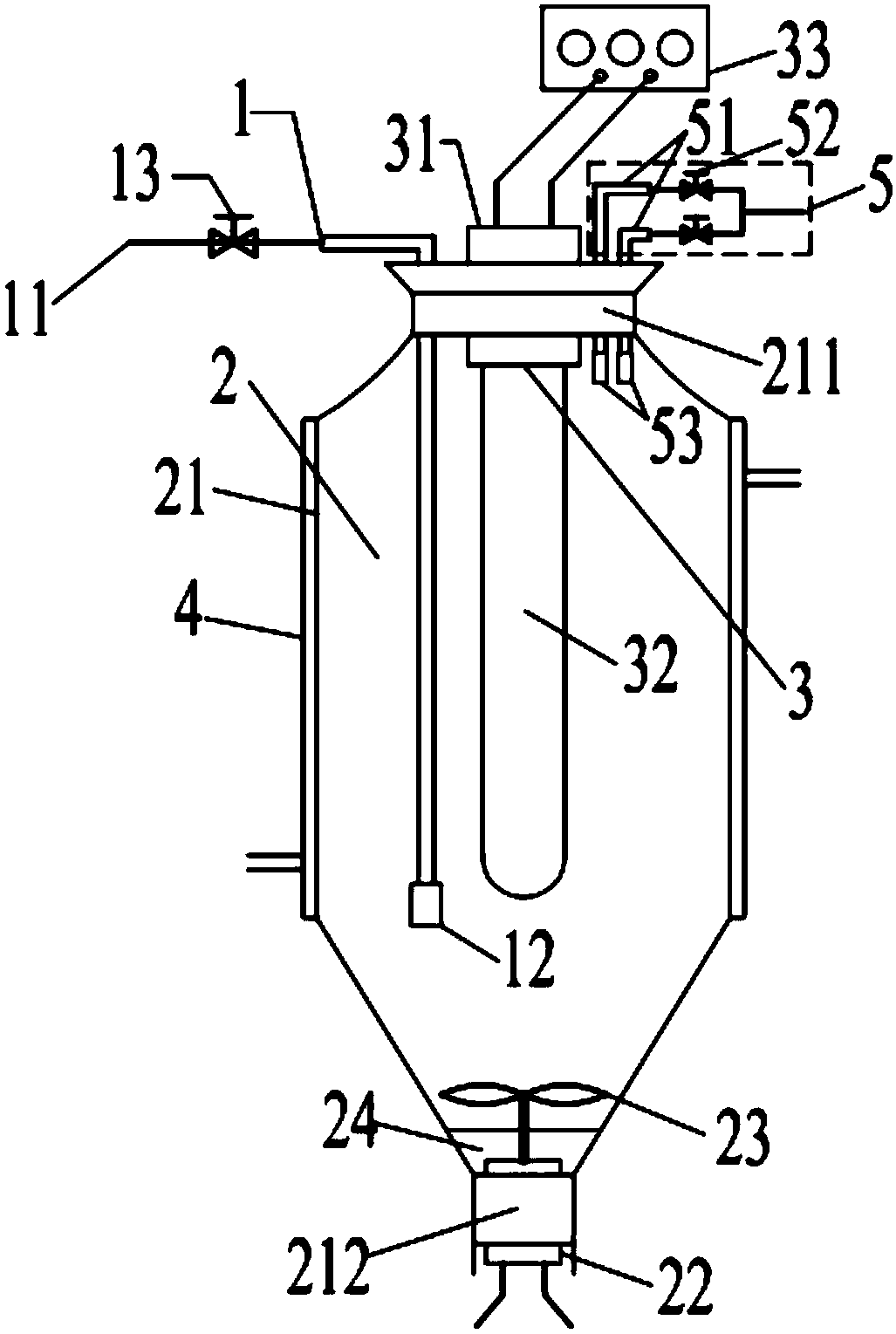

[0030] Example 1 A device for removing organic waste gas by a suspended photocatalyst according to the present invention includes an air inlet device 1 for introducing organic waste gas to be treated, a reactor 2 for catalyzing some components of organic waste gas, and a reactor for providing An ultraviolet irradiation device 3 for ultraviolet light, a circulating cooling device 4 for cooling the reactor, and an exhaust device 5 for discharging harmless gases, the air inlet of the air inlet device 1 communicates with the outside world through a pipe for organic waste gas The gas outlet of the road is connected, and the gas outlet of the air inlet device 1 leads into the inner cavity of the reactor 2; the bottom of the reactor 2 is equipped with a photocatalyst for catalyzing organic waste gas; the top of the reactor 2 is installed with the The ultraviolet irradiation device 3 and the exhaust device 5, and the ultraviolet light emitted by the ultraviolet irradiation device 3 irr...

Embodiment 2

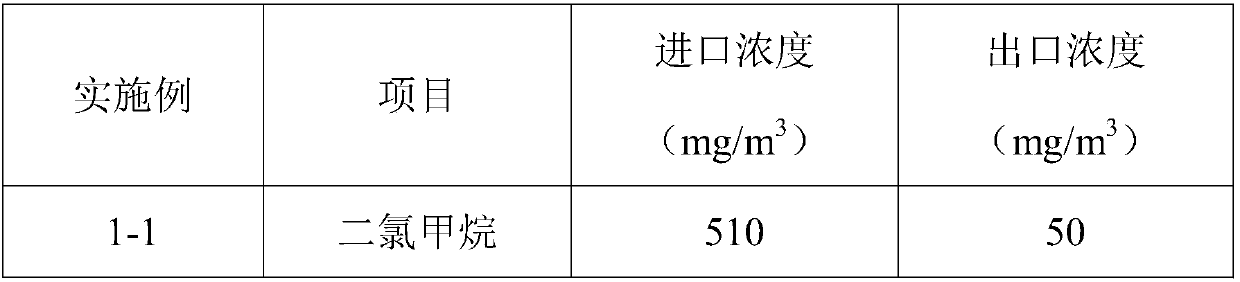

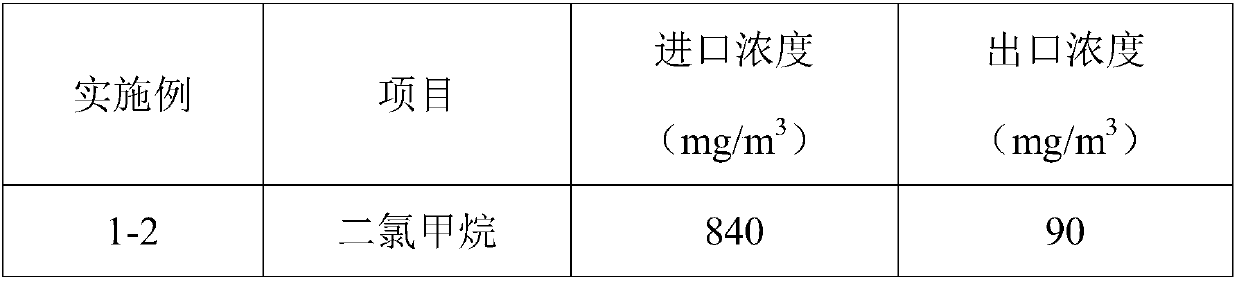

[0046] Structural parameters of the reactor in embodiment 2: the length of the reaction section is 200 mm, the inner diameter is 95 mm, the top installation port of the top rubber plug and the installation section is sealed by polytetrafluoroethylene degreasing raw material tape, and the air leakage is less than 1%; the inner diameter of the top of the catalytic section is 95 mm , the inner diameter of the bottom is 30mm, the height is 70mm, the electric motor with stirring blades is fixed at the bottom, the voltage is 1.5-6V DC, and the lower end is sealed; the length of the ultraviolet lamp is 110mm, the outer diameter is 28mm, and the gas is discharged through the filter B16.

[0047] The experimental conditions are:

[0048] Gas flow: 0.5m 3 / h, the carrier gas is air;

[0049] UV lamp parameters: power 125W, dominant wavelength 365nm;

[0050] The experimental results are shown in Table 1.

[0051] Table 1 Dichloromethane removal effect

[0052]

Embodiment 3

[0054] refer to figure 1 : A device for removing organic waste gas by a suspended photocatalyst. The treatment process is to introduce the gas containing methylene chloride to be treated into the reactor 2 through the inlet conduit 11, and ventilate for a period of time, so that the air in the reactor 2 is completely Replace it, and then turn on the electric motor 22 at the bottom of the reactor. By adjusting the voltage, the rotation speed of the stirring blade 23 can be adjusted, that is, the wind force can be controlled, so that the titanium dioxide catalyst is in a suspended state and contacts with the methylene chloride exhaust gas. Simultaneously, open the switch of circulating cooling device 4, under the irradiation of ultraviolet lamp 32, photocatalyst 24 surface produces electron (e - )-hole (h + ) Yes, the oxygen and water adsorbed on the surface are oxidized into superoxide anions and hydroxyl radicals. These active substances have strong oxidizing properties and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com