Alcohol ester-12 production process

A production process, alcohol ester technology, applied in the production process field of alcohol ester-12, can solve the problems of difficult control, long process flow, complicated process, etc., and achieve the effect of convenient operation, simple process and broad market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

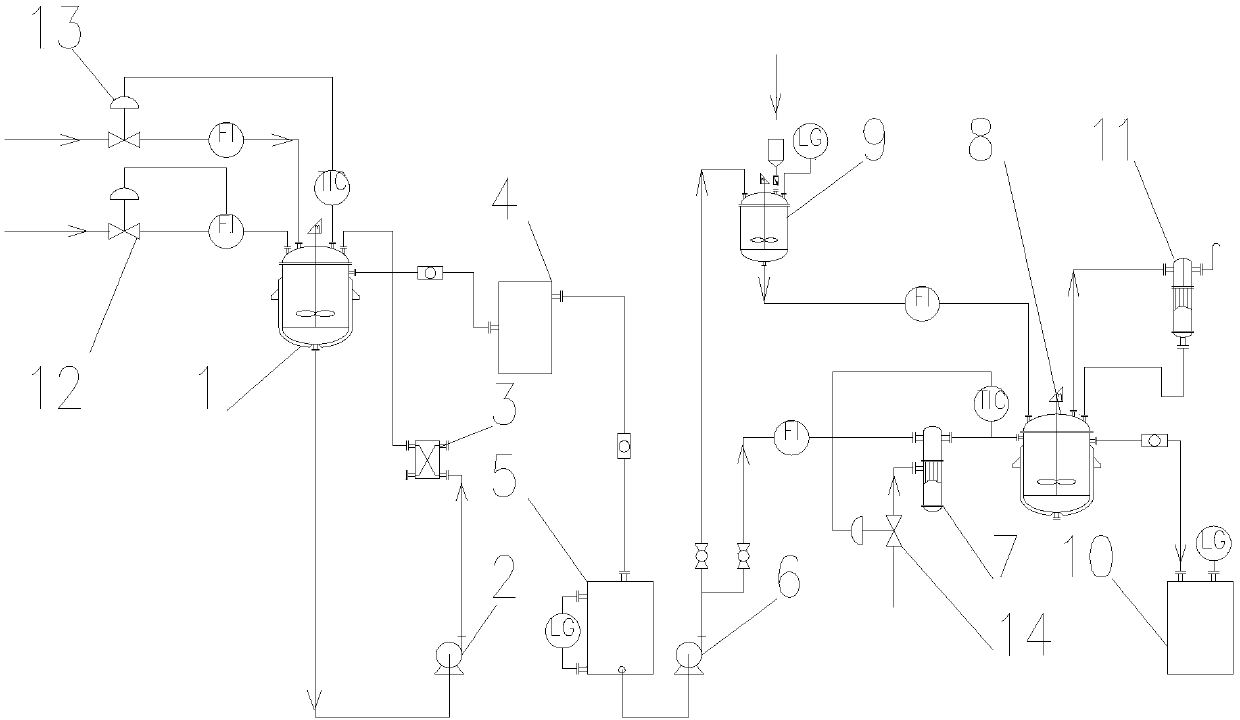

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] Such as figure 1 as shown,

[0033] A kind of production technology of alcohol ester-12, comprises the following steps:

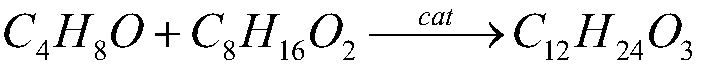

[0034] A, a catalytic reaction

[0035] The one-stage catalytic reaction is polycondensation reaction, and the reaction equipment is a reactor. The process is as follows:

[0036] (1) Preparatory stage: Check the instruments on the first-stage reaction kettle (1) and the first-stage reaction circulation pump (2) to make them in good condition; open the jacket of the first-stage reaction kettle (1) and the first-stage reaction circulation cooler (3) Circulating water valve to circulate cooling water.

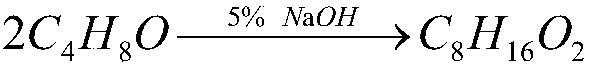

[0037] (2) the reaction process is that the dilute alkaline water sodium hydroxide of 5% by mass fraction enters one section of reactor (1) through the flow control of dilute alkali feed regulating valve (12) throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com