Method for dimension measurement of hardware parts based on CCD area-array camera visual inspection

A technology for hardware parts and visual inspection, applied in the field of image processing, can solve the problems of high inspection accuracy, failure to meet the required inspection level, and machine vision technology is not particularly perfect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

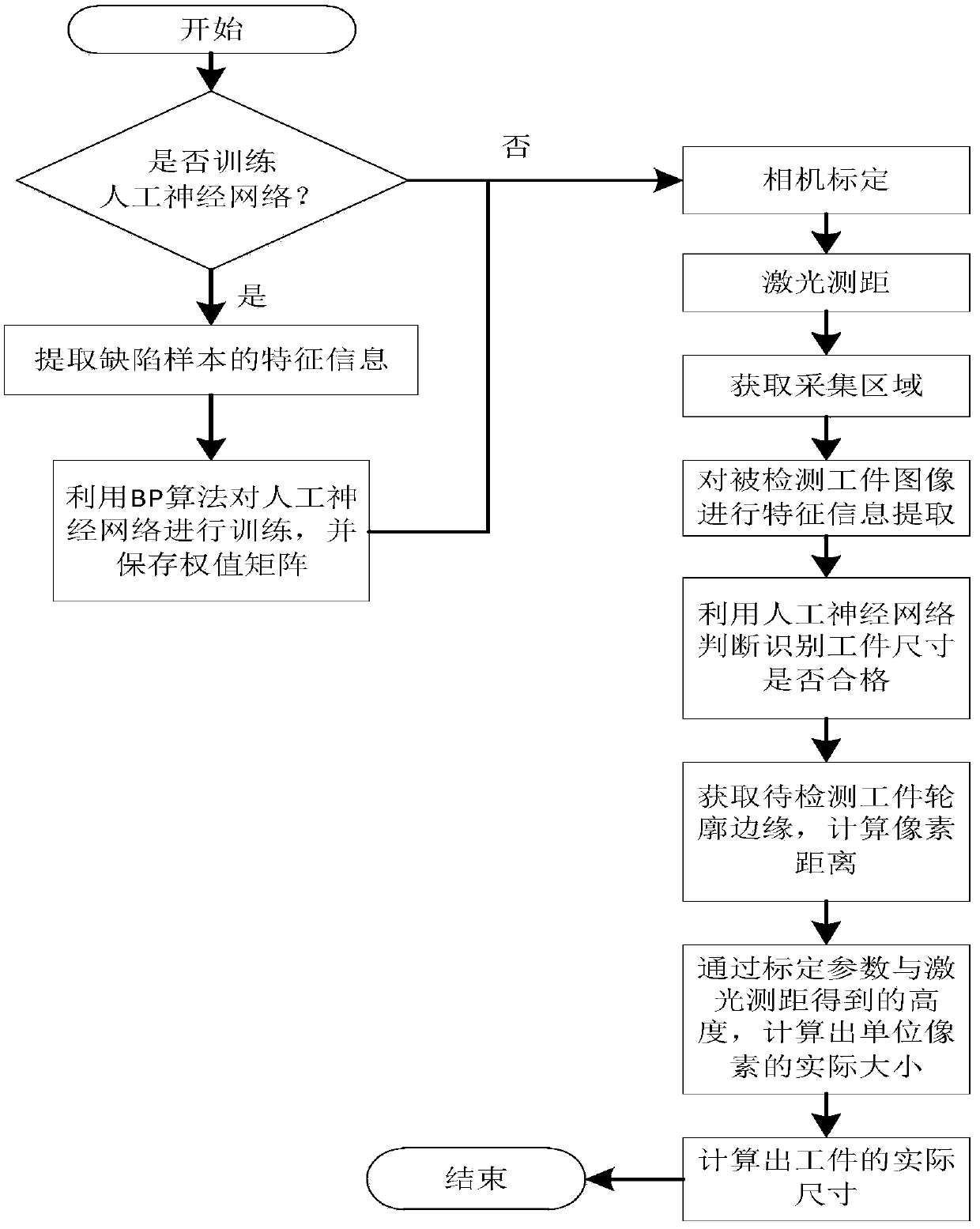

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments.

[0038] A method for measuring the size of hardware parts based on CCD area array camera visual detection, comprising the following steps;

[0039] A. Determine whether to train the artificial neural network, if not, perform the training of the artificial neural network;

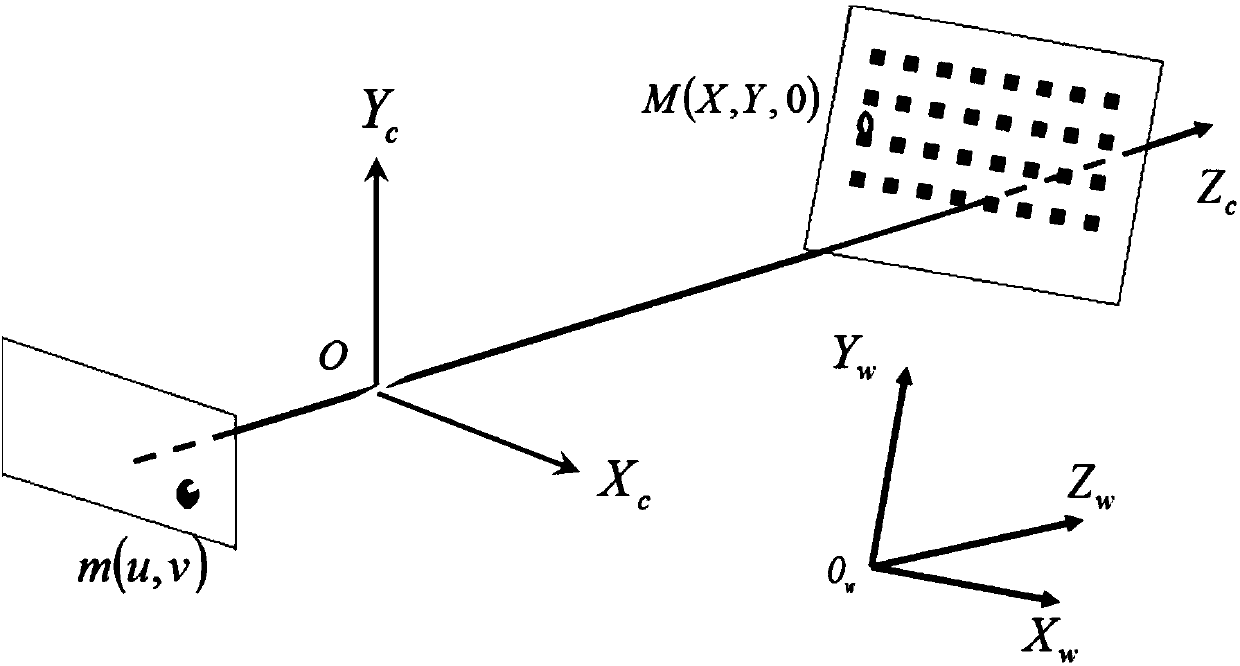

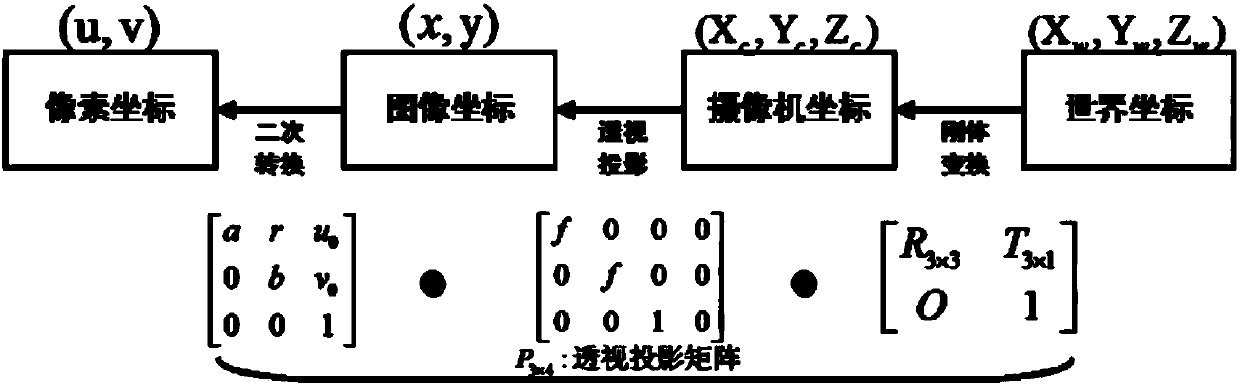

[0040] B. Carry out camera correction by collecting multiple calibration board images, and save relevant calibration information;

[0041] C. Set up a laser sensor at the light-emitting point of the camera to measure the vertical distance from the light-emitting point of the lens to the detection surface;

[0042] D. The computer triggers and controls the industrial camera through the software to take pictures of a hardware part with a standard size as the original image sample, and collect the template area in the clear image;

[0043] E. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com