Warming paste

A technology of warming baby and inner core layer, which is applied in the direction of phototherapy, heating equipment for treatment, cooling equipment for treatment, etc., can solve the problem of inconvenient use of warming baby, prolong heating time, improve human health, The effect of significant resonance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

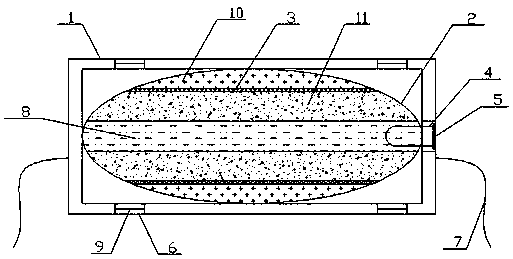

Embodiment 1

[0021] A warm baby, comprising: an outer bag layer 1, an inner bag layer 2, a separation layer 3, an electric heating rod 4, a power interface 5, a ventilation hole 6, a strap 7, an inner core layer 8, a sealing film 9, and a first inner cavity 10. The second inner cavity 11; the inner bag layer 2 is arranged inside the outer bag layer 1, the inner core layer 8 is horizontally arranged at the inner center of the inner bag layer 2, the inner core layer 8 and the surface layer of the inner bag layer 2 A separation layer 3 is arranged between them, a second inner chamber 11 is formed between the inner core layer 8 and the separation layer 3, a first inner chamber 10 is formed between the separation layer 3 and the surface layer of the inner bag layer 2, and the outer The right end of the bag layer 1 is provided with a power supply structure, the right end of the inner bag layer 2 is provided with an electric heating rod 4, the electric heating rod 4 is located inside the inner cor...

Embodiment 2

[0032] The difference between Embodiment 2 and Embodiment 1 is that: the first inner cavity is provided with a heating material, and the heating material is made of the following components in parts by weight: iron powder 90, activated carbon 20, water 40, bentonite 8, Sericite powder 5, carboxymethylated starch 5;

[0033] The second inner cavity is provided with an active material, and the active material is made of the following components by weight: tourmaline powder 18, turpentine 25, sandalwood powder 5, white lilac pollen 8;

[0034] The inner core layer is provided with a liquid, and the liquid is made of the following components in parts by weight: nano diatomite 5, sodium polyacrylate 8, and water 115 .

[0035] Further, the iron powder contains 0.35% silicon powder by mass.

[0036] Further, the activated carbon is coconut shell activated carbon.

[0037] Further, the particle sizes of the bentonite and sericite powder are both 150 mesh.

[0038] Further, the pre...

Embodiment 3

[0042] The difference between embodiment 3 and embodiment 1 is that a heating material is provided in the first inner cavity, and the heating material is made of the following components in parts by weight: iron powder 85, activated carbon 18, water 38, bentonite 7, silk Mica powder 4, carboxymethylated starch 4;

[0043] The second inner cavity is provided with an active material, and the active material is made of the following components by weight: tourmaline powder 15, turpentine 22, sandalwood powder 4, white lilac pollen 7;

[0044] The inner core layer is provided with a liquid, and the liquid is made of the following components in parts by weight: nano diatomite 4, sodium polyacrylate 7, and water 112 .

[0045] Further, the iron powder contains 0.35% silicon powder by mass.

[0046] Further, the activated carbon is coconut shell activated carbon.

[0047] Further, the particle sizes of the bentonite and sericite powder are both 150 mesh.

[0048] Further, the prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com