Ammonia-containing waste gas absorption system

An absorption system and waste gas technology, applied in the field of ammonia-containing waste gas absorption system, can solve the problems of increased acid solution consumption, etc., and achieve the effects of improving operating flexibility, increasing concentration, and improving absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

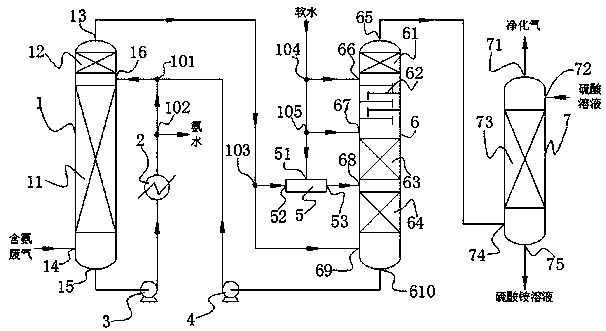

[0015] An ammonia-containing exhaust gas absorption system, comprising: a first absorption tower (1), a heat exchanger (2), a first centrifugal pump (3), a second centrifugal pump (4), a Venturi mixer (5), a The second absorption tower (6) and the third absorption tower (7); the first absorption tower (1) is provided with the first mist eliminator (12) and the first packing (11) sequentially from top to bottom, the first absorption tower (1) The top is provided with a first air outlet (13), the bottom is provided with a first water outlet (15), the side is lower than the first packing (11) is provided with a first air inlet (14), and the side is located at The position between the first demister (12) and the first filler (11) is provided with a first water inlet (16); the heat exchanger (2) is provided with an inlet and an outlet; the first centrifugal pump (3) and the second The two centrifugal pumps (4) are respectively provided with their own inlets and outlets; the Venturi...

Embodiment 2

[0024] Except that the opening ratio of the valve tray (62) of the second absorption tower (6) is 15%, all the other contents are the same as in Example 1.

Embodiment 3

[0026] Except that the opening ratio of the valve tray (62) of the second absorption tower (6) is 18%, all the other contents are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com