Automatic glue removal system and method, and application thereof

An automatic wiping and glue technology, applied in labels, packaging, labeling machines, etc., can solve the problem of manual wiping glue affecting production efficiency, and achieve the effect of simple and convenient use, easy operation, and saving consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

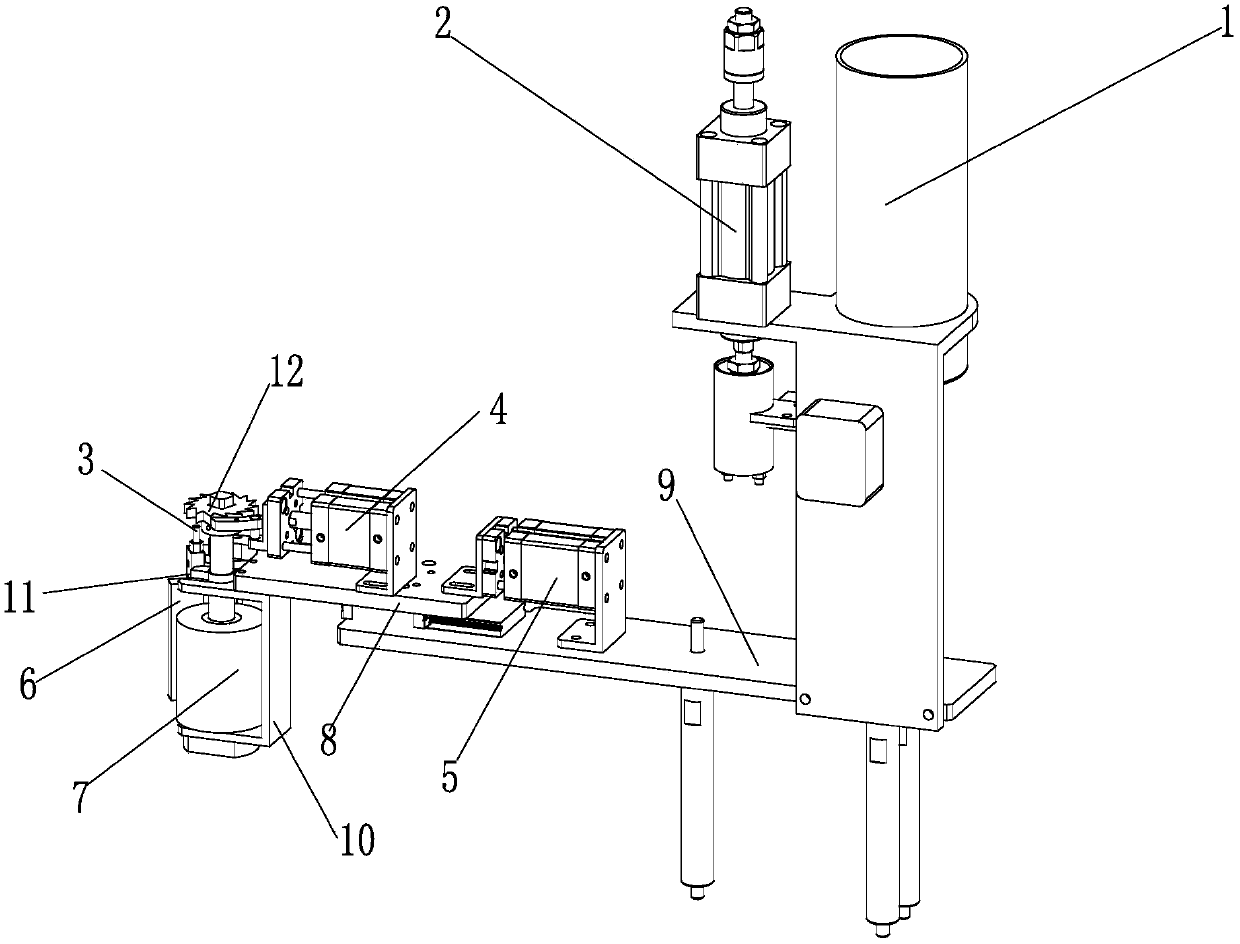

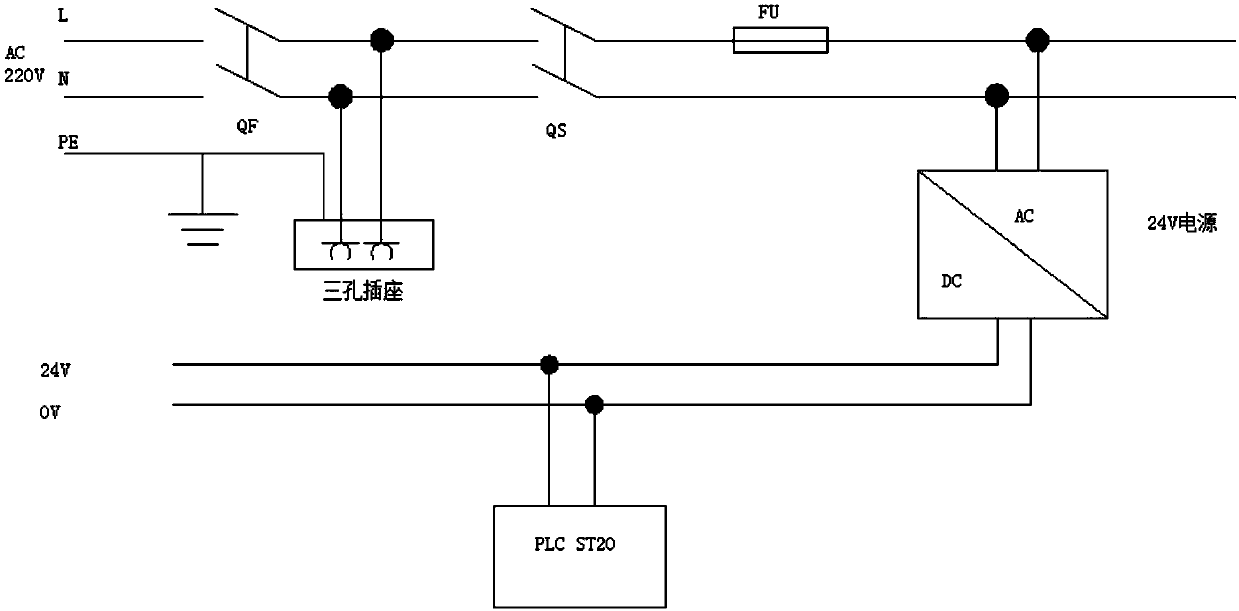

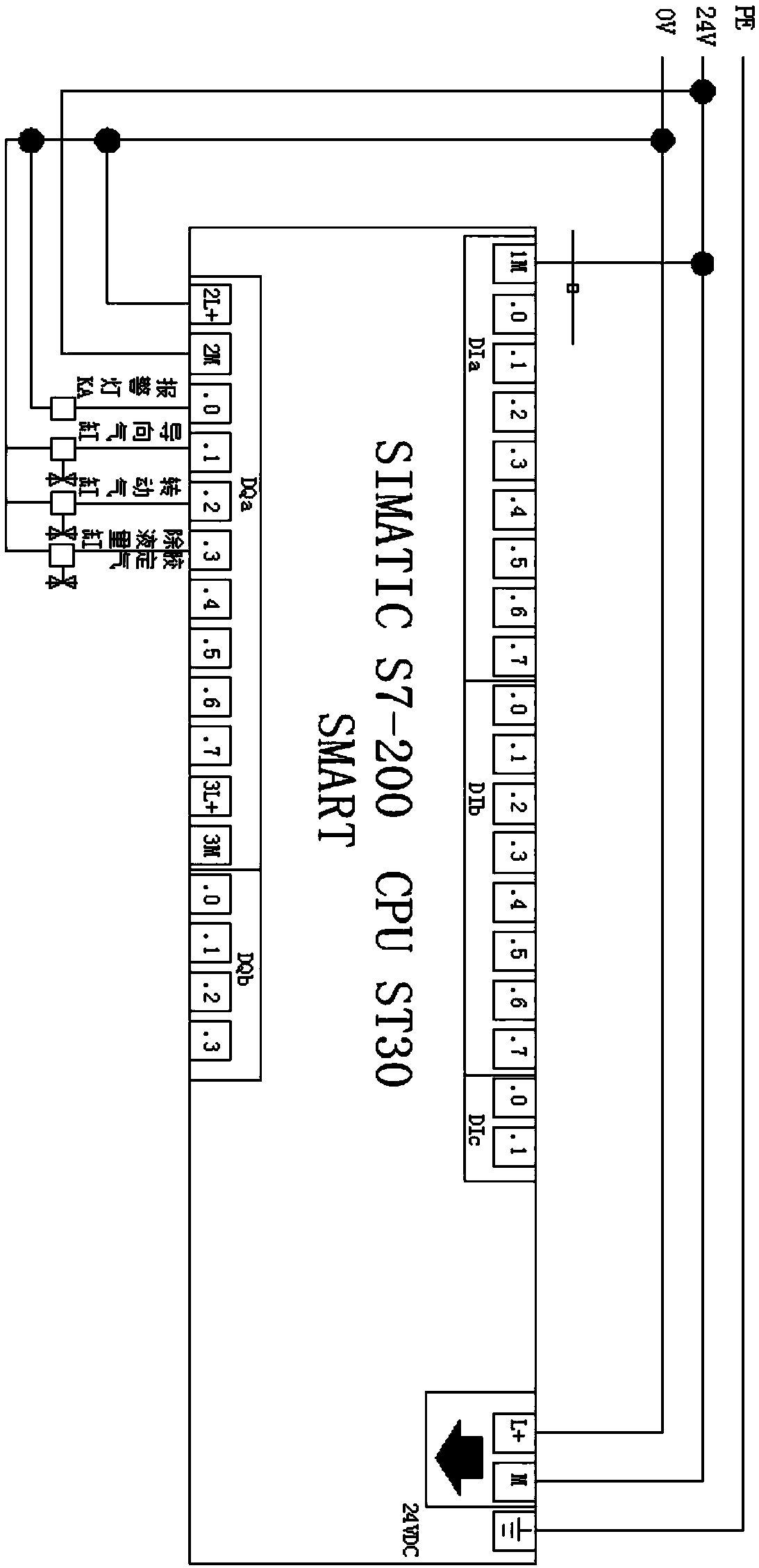

[0050] An automatic rubbing system, such as figure 1As shown, it is used for degumming the object to be degummed, including the electrical control module, the degumming liquid quantitative output module, the degumming liquid temporary storage module, the glue wiper assembly cut-in and exit module, the glue wiper assembly rotation module and the glue wiper assembly ;The electrical control module is respectively connected to the quantitative output module of the glue removing liquid, the cutting and exiting module of the glue wiping assembly and the rotating module of the glue wiping assembly, and is used to control the quantitative output module of the glue removing liquid to output the glue removing liquid, and to control the cutting of the glue wiping assembly. Exit timing and rotation of the glue-wiping component; the glue-removing liquid quantitative output module receives instructions from the electrical control module and outputs a quantitative glue-removing liquid; the gl...

Embodiment 2

[0062] An automatic glue-wiping method, comprising the following steps:

[0063] Detect whether the cut-in time is reached, and if so, the electrical control module generates a cut-in signal, and the glue-wiping component cut-in and exit module receives the cut-in signal and performs the cut-in action, and cuts in the glue-wiping assembly rotation module and the glue-wiping assembly;

[0064] The electrical control module generates the glue removal signal, the glue removal quantitative cylinder receives the glue removal signal, and the glue removal quantitative cylinder provides power to make the glue temporary storage device to spray glue, and the glue removal finally passes through the glue removal nozzle. 3. Spray it out, and carry out the degumming operation on the object to be degummed by wiping the adhesive cloth;

[0065] After a glue removal operation is completed, the electrical control module generates a rotation signal to control the action of the rotating cylinder,...

Embodiment 3

[0068] An application of an automatic glue wiping system, which is used for wiping glue on objects to be removed from a labeling machine. In this embodiment, the automatic glue-wiping system is used on the labeling machine and used in conjunction with other components of the labeling machine to remove the glue from the object to be removed. The module receives the cut-in signal and executes the cut-in action to cut in the glue wiper assembly rotation module and the glue wiper assembly; the electrical control module generates a glue output signal, the glue removal quantitative cylinder 2 receives the glue output signal, and the glue removal quantitative cylinder 2 provides The power makes the glue liquid temporary storage device discharge liquid, and the glue removal liquid is finally sprayed out through the glue removal liquid nozzle 3, and the glue removal cloth is used to wipe the glue on the object to be removed. After wiping the glue, the electrical control module generate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com