Double-station feeding mechanism with cleaning function

A feeding mechanism and double-station technology, applied to conveyor objects, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problem of corrosion and oxidation of the conveyor chain, easy glaze accumulation on the conveyor chain, and defective products, etc. problem, to achieve the effect of structural installation and control realization, easy structural installation and control, and meeting production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

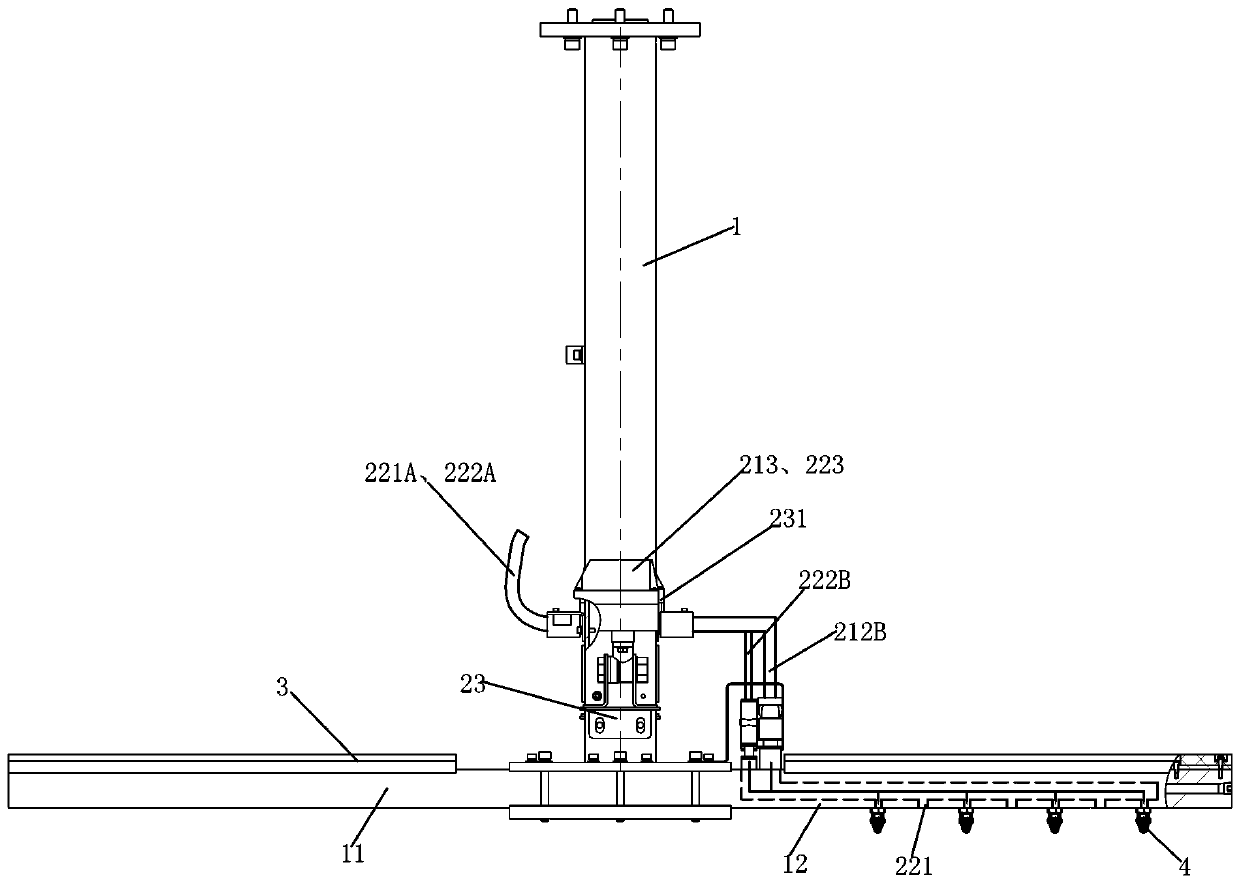

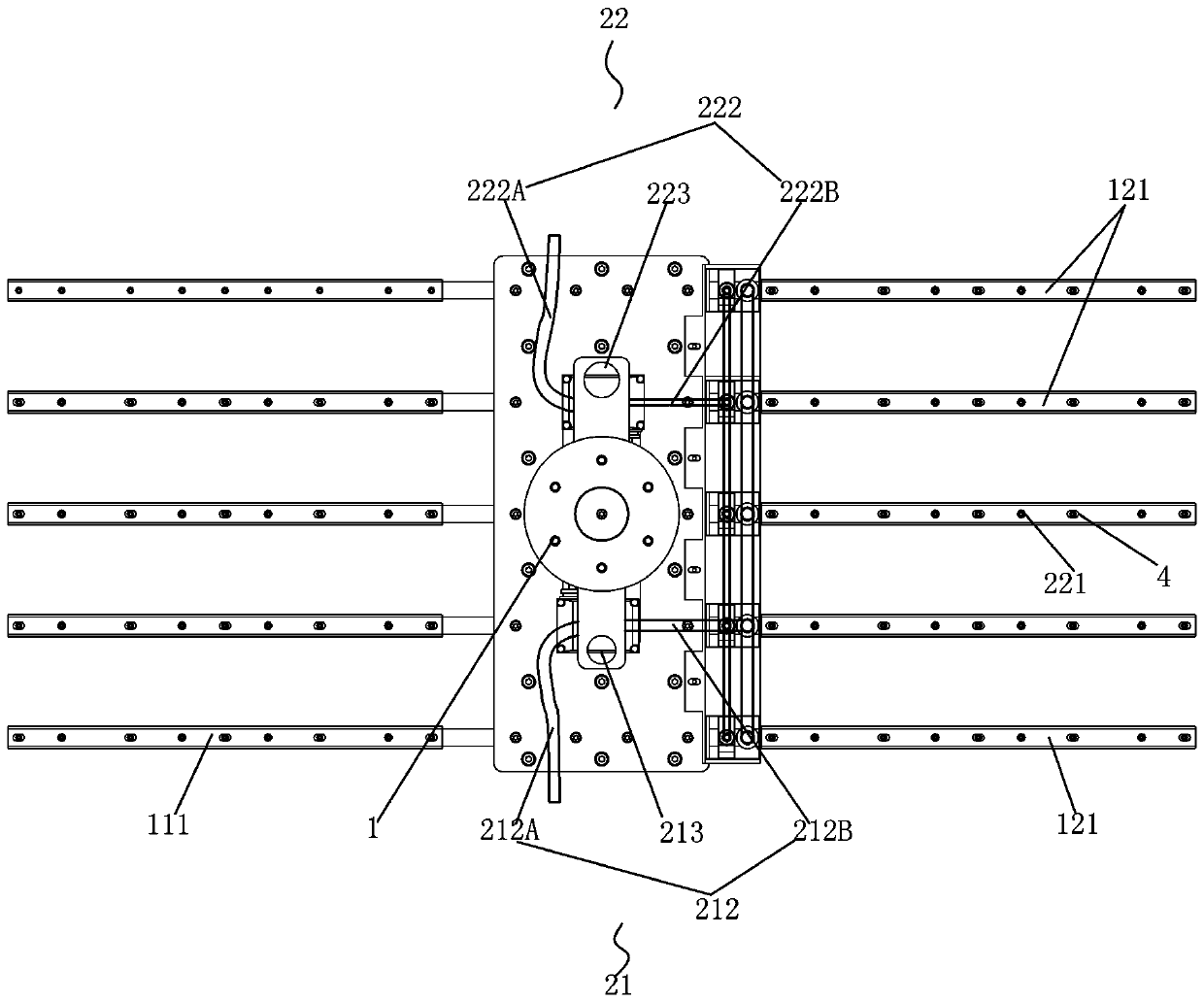

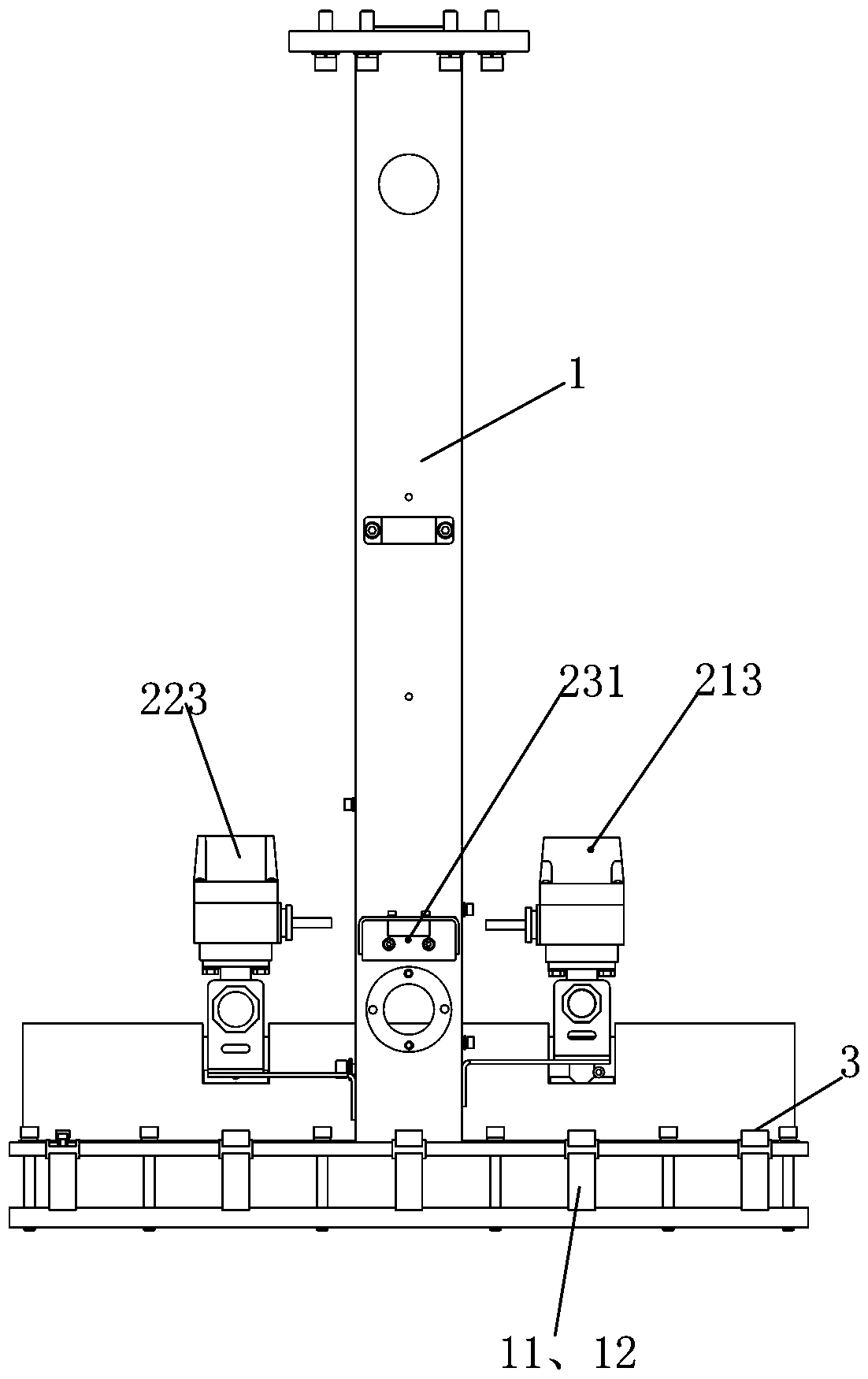

[0048] Specific implementation methods, such as Figure 1 to Figure 6 As shown, a double station feeding mechanism with cleaning function according to the present invention mainly includes the following components: frame 1, first and second object receiving platforms 11, 12, soft anti-collision strip 3, water spray Seat 41, rotating head 42, water seat 43, water inlet plate 44, counterweight ball 45, water supply pipeline 212, first control valve 213, blowing nozzle 221, air supply pipeline 222, second control valve 223, induction Component 231 and the main control component;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com