Durable cement concrete road slab bottom grouting material and preparation method thereof

A cement concrete road, durable technology, applied in the field of road engineering materials, can solve the problems of poor durability of the road surface, achieve good water dispersion resistance, improve stability, and reduce the effect of grouting pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

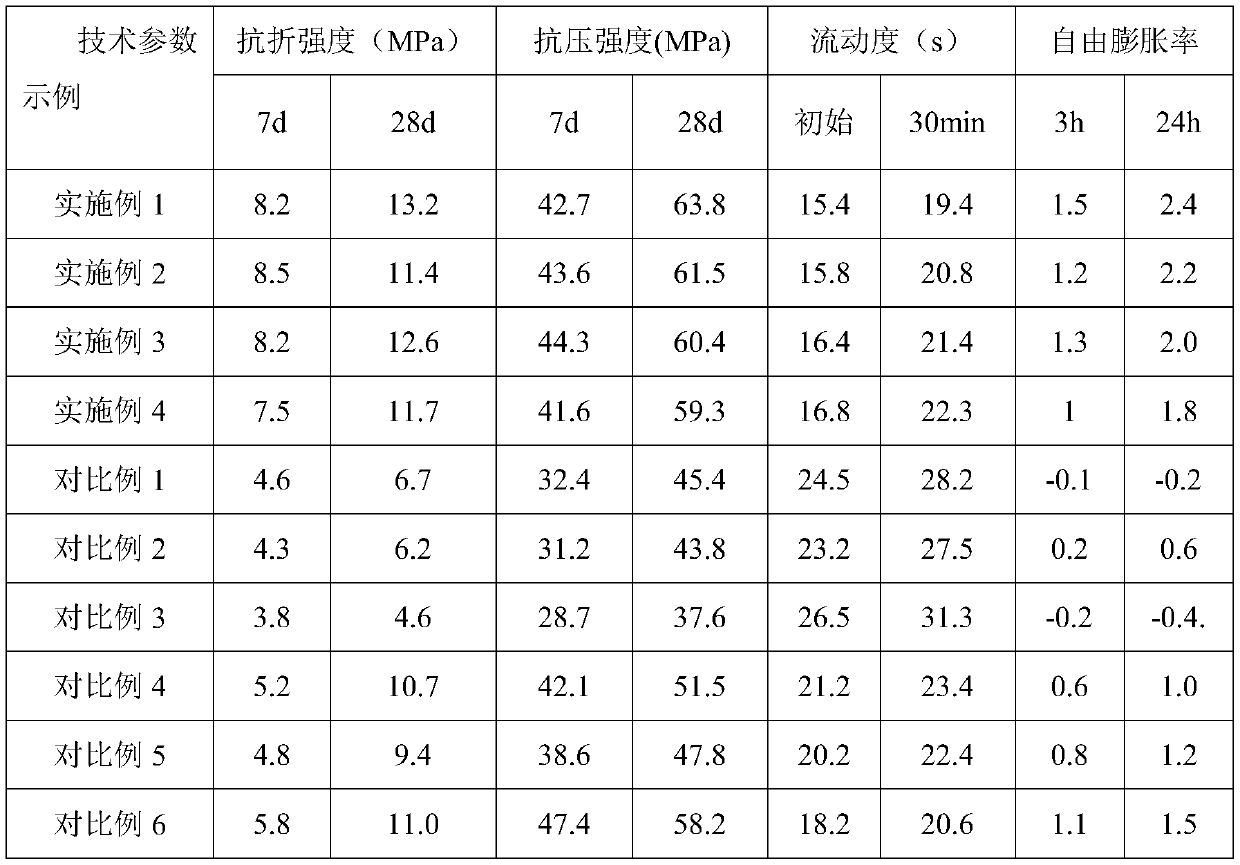

Examples

Embodiment 1

[0034] This embodiment provides a kind of durable cement concrete pavement bottom grouting material, and this grouting material is made of the following raw materials in terms of weight fraction: cement is 32%, fly ash is 27%, and water reducer is 0.50%, complexing agent 5%, complex A 8%, complex B 7%, water 20.5%;

[0035] The composite A is made of the following raw materials in terms of weight fraction: 70% of precipitated silica, 5% of asbestos, and 25% of attapulgite;

[0036] The composite B is made of the following raw materials in terms of weight fraction: 80% of sepiolite, 5% of superabsorbent resin, and 15% of magnesium oxide expansion agent.

[0037] In this example:

[0038] The complexing agent is powdered sodium ethylenediaminetetramethylene phosphate with a fineness of 300 mesh.

[0039] The cement is 42.5 grade quick-hardening sulfoaluminate cement with an apparent density of 3.0-3.2g / cm 3 .

[0040] Fly ash is a first-class fly ash with an apparent density...

Embodiment 2

[0053] This embodiment provides a durable cement concrete road slab bottom grouting material, the grouting material is made of the following raw materials in terms of weight fraction: 35% of cement, 25% of fly ash, and 25% of water reducer 0.55%, complexing agent 5%, complex A 6%, complex B 7%, water 21.45%.

[0054] The composite A is made of the following raw materials in terms of weight fraction: 60% of precipitated silica, 15% of asbestos, and 25% of attapulgite;

[0055] The composite B is made of the following raw materials in terms of weight fraction: 80% of sepiolite, 5% of superabsorbent resin, and 15% of magnesium oxide expansion agent.

[0056] The kind and consumption requirement of each raw material in the present embodiment are identical with embodiment 1.

[0057] The preparation method of the durable cement concrete pavement bottom grouting material of this embodiment is basically the same as that of Embodiment 1.

[0058] The performance test process of this...

Embodiment 3

[0060] This embodiment provides a kind of durable cement concrete pavement bottom grouting material, and this grouting material is made of the following raw materials in terms of weight fraction: cement is 38%, fly ash is 22%, and water reducing agent is 0.45%, complexing agent 5%, complex A 6%, complex B 5%, water 23.55%;

[0061] The composite A is made of the following raw materials in terms of weight fraction: 70% of precipitated silica, 10% of asbestos, and 20% of attapulgite;

[0062] The composite B is made of the following raw materials in terms of weight fraction: 80% of sepiolite, 10% of superabsorbent resin, and 10% of magnesium oxide expansion agent.

[0063] The kind and consumption requirement of each raw material in the present embodiment are identical with embodiment 1.

[0064] The preparation method of the durable cement concrete pavement bottom grouting material of this embodiment is basically the same as that of Embodiment 1.

[0065] The performance test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com