Method for preparing YAG transparent ceramic by gel casting

A technology for gel injection molding and transparent ceramics, which is applied in the field of preparing YAG transparent ceramics by gel injection molding, and can solve the problems of uneven dispersion and slow gel forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

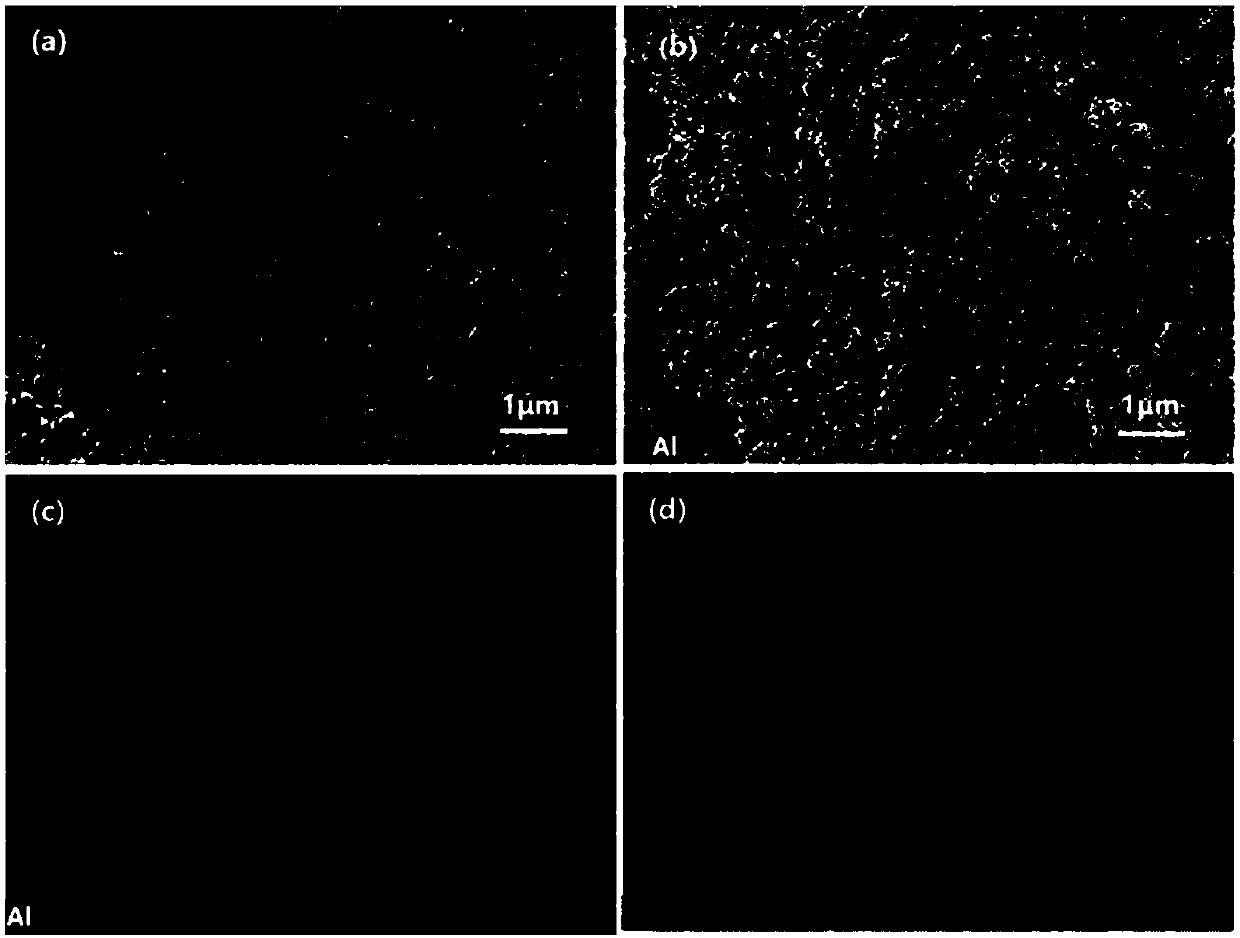

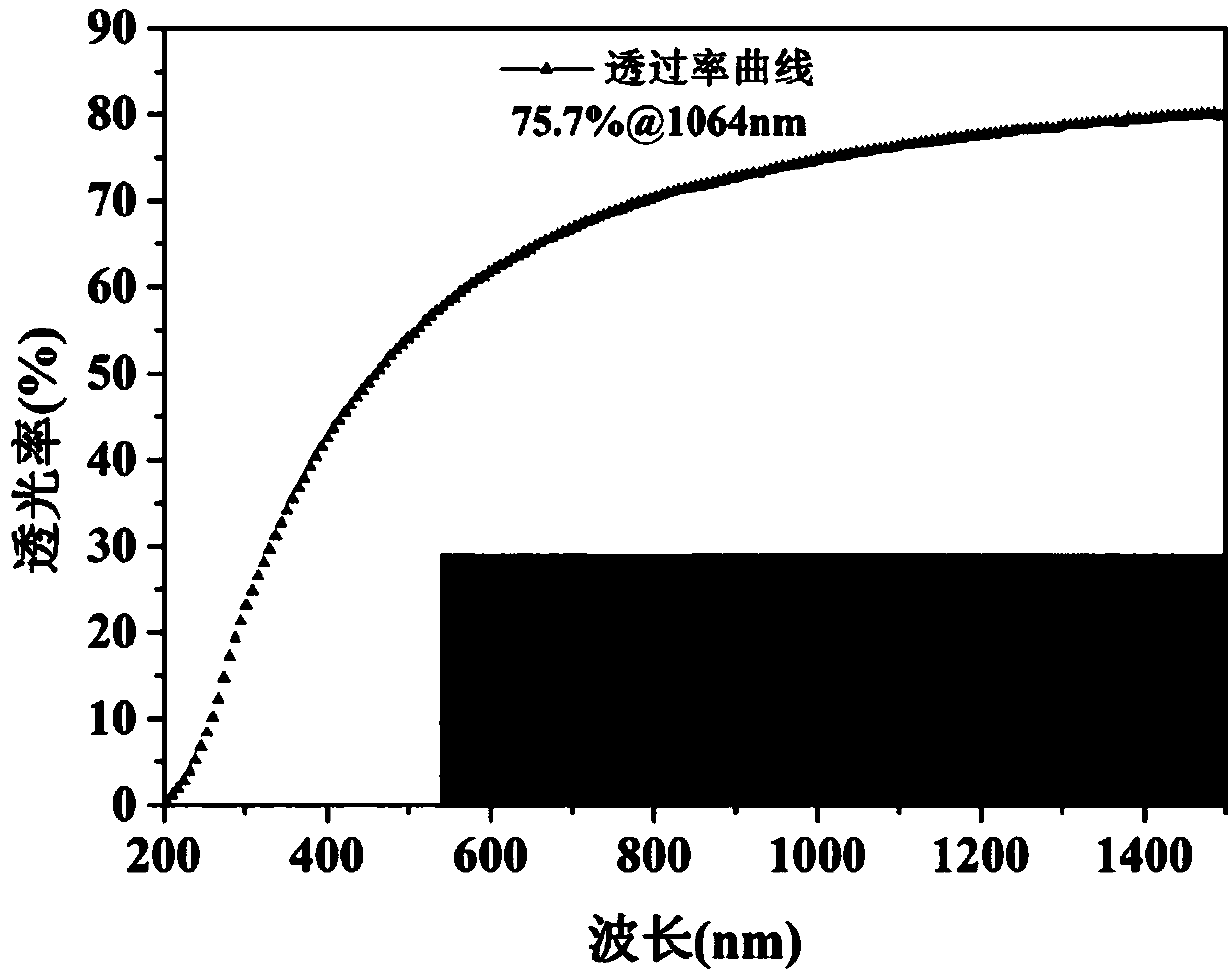

Image

Examples

Embodiment Construction

[0025] A method for preparing YAG transparent ceramics by gel injection molding; the method includes the preparation of YAG ceramic slurry, vacuum defoaming, catalyst addition, injection into mold curing, demoulding, drying, debinding, and firing; specifically includes the following step:

[0026] Step 1. Follow Y 3 al 5 o 12 The stoichiometric ratio of the molecular formula weighs Y 2 o 3 Powder, Al 2 o 3 The powder is used as a ceramic powder, and a sintering aid is added to obtain an oxide mixture;

[0027] Step 2: Premix the oxide mixture with balls and a solvent to form a premixed solution, and mix and ball mill for 15 to 24 hours to obtain a mixed slurry;

[0028] Step 3. After the mixed slurry is dried in an oven, calcined in a muffle furnace, and sieved to 100-200 mesh as raw material powder for gel injection molding;

[0029] Step 4, add raw material powder and defoamer to the Isobam solution, and stir with a stirrer at a constant temperature;

[0030] Step 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com