PVC threading pipe and preparation method thereof

A technology of threading pipe and stabilizer, which is applied in the field of PVC threading pipe and its preparation, can solve the problems of insufficient compressive strength, loss of life and property safety, and inability to pass through, and achieve high flame retardancy, strong compressive performance, The effect of good bending properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

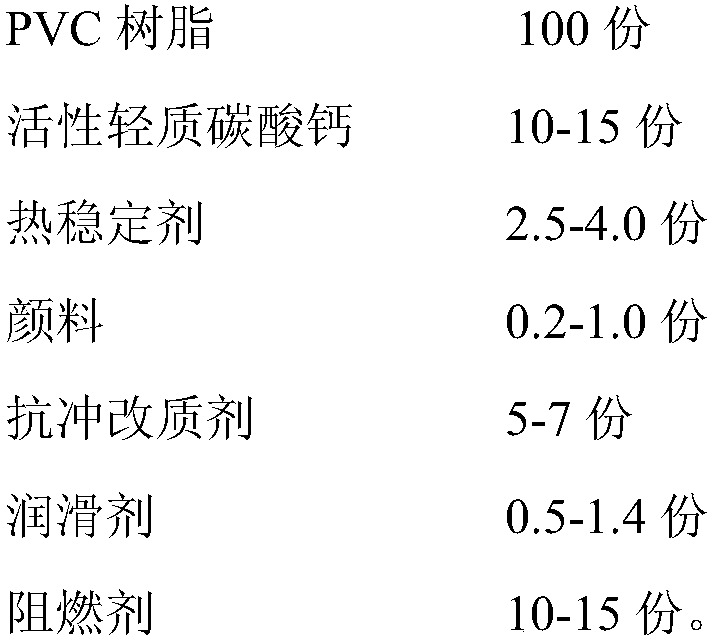

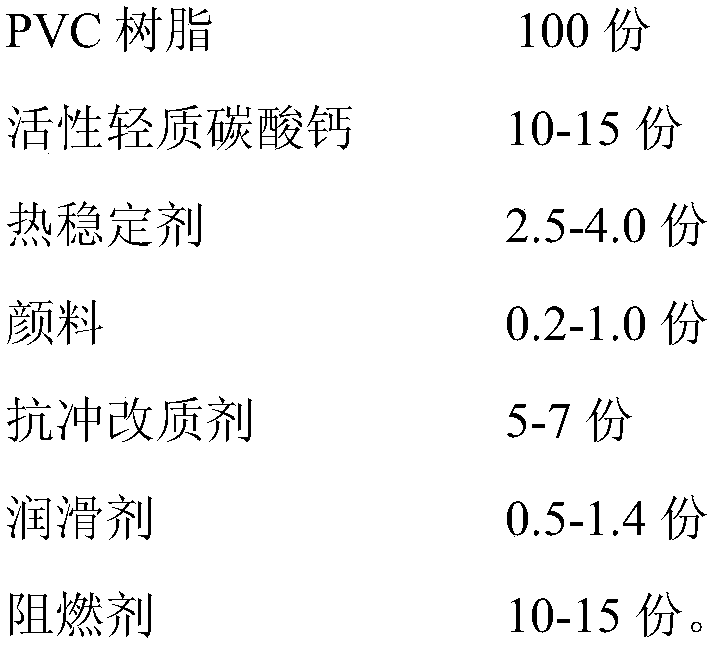

[0037] PVC in parts by mass: 100 active CaCO 3 : 15 impact modifier CPE: 5 heat stabilizer composite lead salt stabilizer: 3.5AL(OH) 3 [B]: 12 Pigment titanium dioxide: 0.8 Lubricant PE wax: 1.1, produce PVC 20 heavy-duty threading pipe, its OI is 50, and its compressive strength is 1750N.

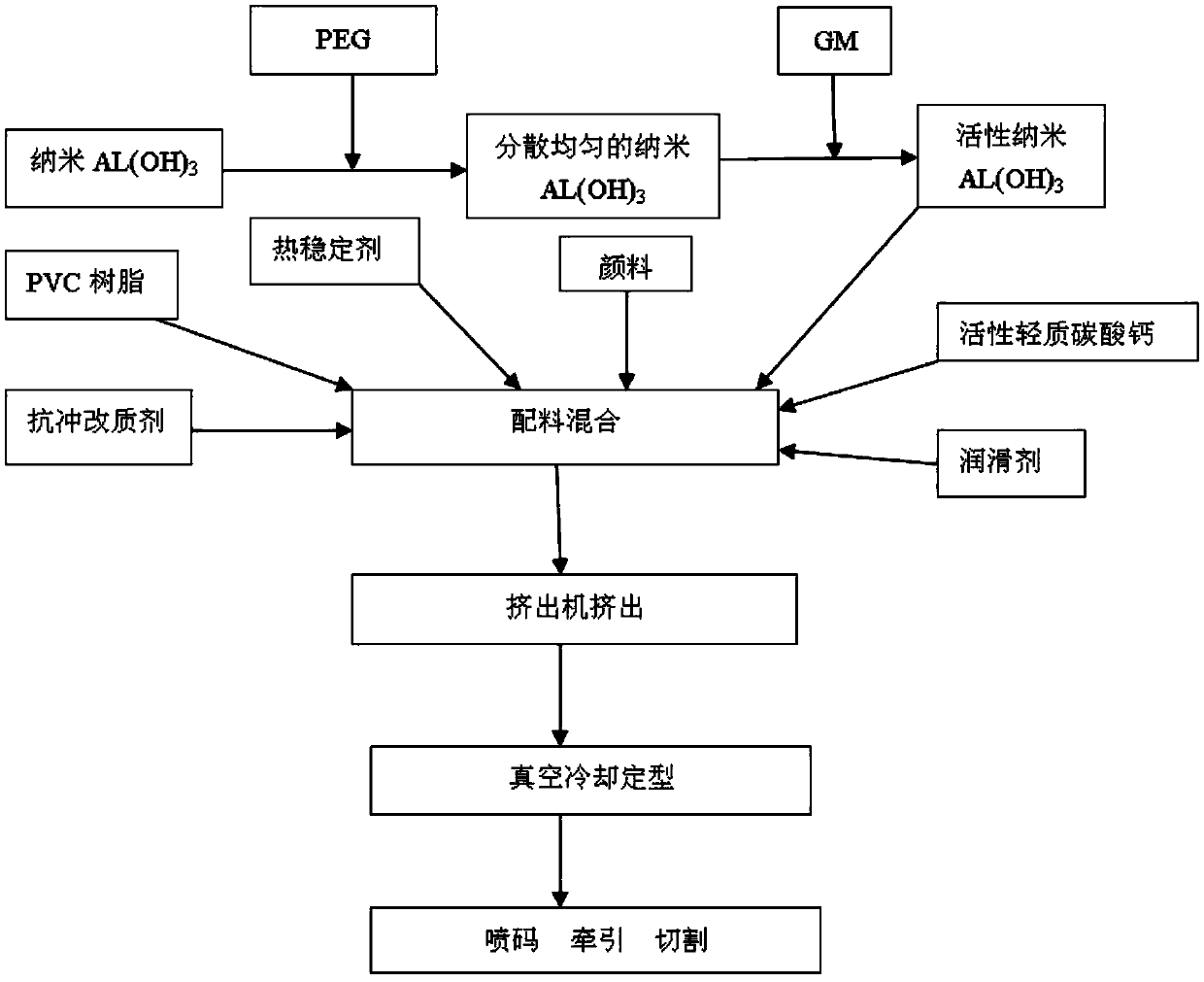

[0038] The preparation method is as follows:

[0039] (1) Batching and mixing: mix PVC resin, active light calcium carbonate, flame retardant, impact modifier, heat stabilizer, pigment and lubricant, and use a high-speed mixer to stir the above materials to obtain uniform dispersion Compound powder, and remove the moisture contained in the raw material through frictional heat generation;

[0040] (2) Extrusion by extruder: the mixed material is fed into the extruder from the hopper, and through the process of screw compression and plasticization, the material is converted into a high-viscosity elastic body, and is continuously extruded through the mold;

[0041] (3) Vacuum cooling and s...

Embodiment 2

[0047] PVC in parts by mass: 100 active CaCO 3: 15 anti-impact modifier anti-impact ACR: 5 heat stabilizer composite calcium zinc stabilizer: 3.5AL(OH) 3 [B]: 10 pigment titanium dioxide: 0.8 lubricant PE wax: 1.1, produce PVC 20 heavy-duty threading pipe, its OI is 46, and its compressive strength is 1646N. The preparation method is the same as in Example 1.

Embodiment 3

[0049] PVC in parts by mass: 100 active CaCO 3 : 15 impact modifier MBS: 5 heat stabilizer composite calcium zinc stabilizer: 3.5AL(OH) 3 [B]: 15 pigment titanium dioxide: 0.8 lubricant microcrystalline wax: 1.1, produce PVC 20 heavy-duty threading pipe, its OI is 54, and its compressive strength is 1724N. The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com