Aluminum alloy strip for mobile phone battery shell and manufacturing method thereof

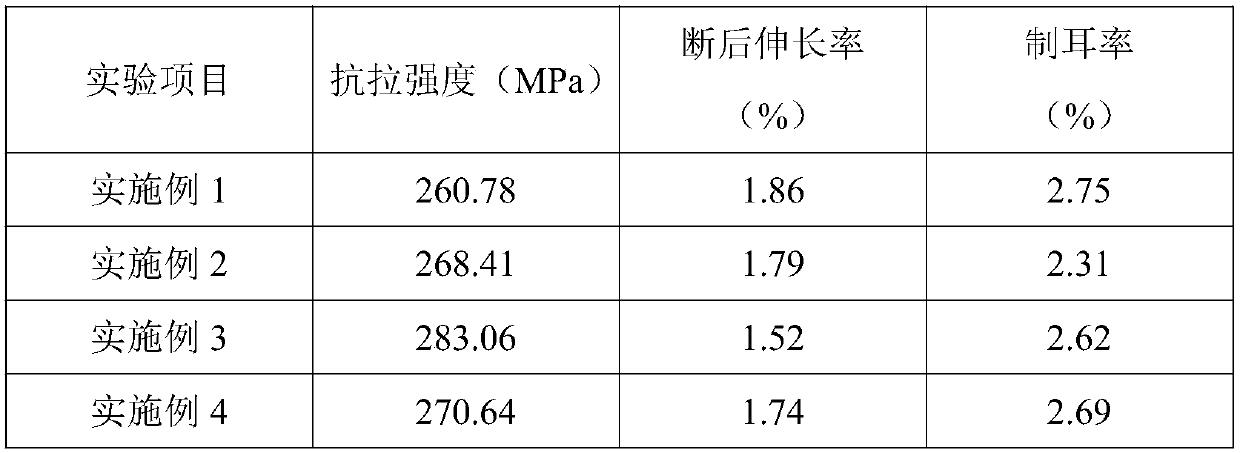

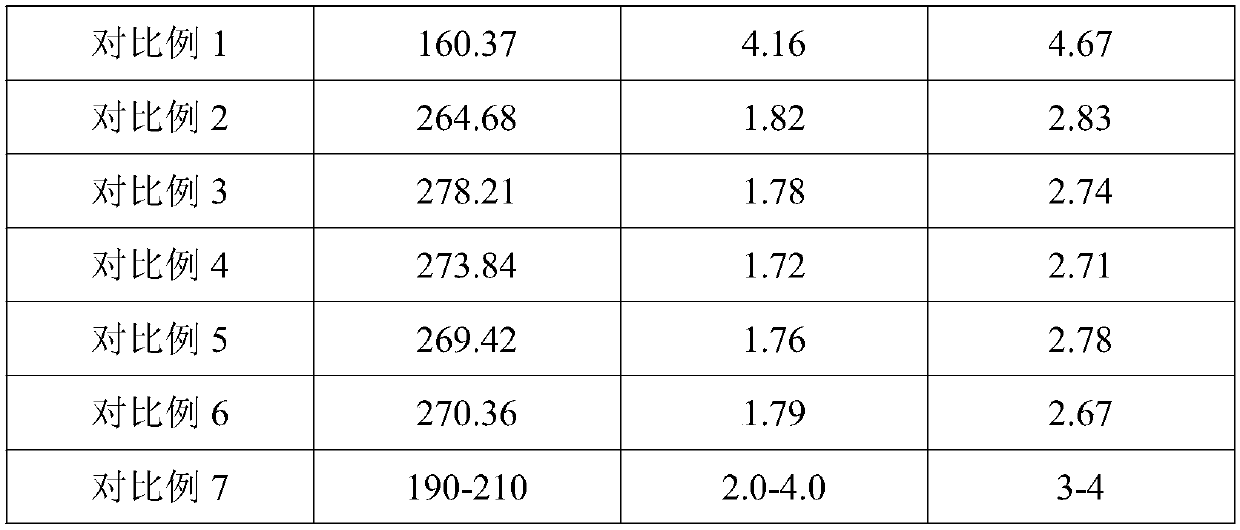

A technology for aluminum alloy strips and mobile phone batteries, which is applied to the field of aluminum alloy strips for mobile phone battery shells, can solve the problem of elongation after breaking, large ear-making rate, inability to meet the requirements of large-scale thinning and stretching and punching, and resistance to Low tensile strength, etc., to achieve the effect of high tensile strength, meeting the requirements of proportional thinning and stretch punching, and low ear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the aluminum alloy strip for the cell phone battery case comprises the following steps:

[0026] S1. Melting: Use a gas reactor to melt the prepared materials. After melting, the unit of weight is 1.2-4 parts of silicon, 1.5-4 parts of iron, 4-8 parts of copper, 0.8-1.5 parts of magnesium, and 0.3 parts of manganese. -0.9 parts, 3-8 parts of zinc, 8-10 parts of titanium, 1.8-2.6 parts of tin, 0.8-1.5 parts of chromium, 3-5 parts of nickel, 0.2-0.4 parts of graphene, 0.5-0.9 parts of sodium fluorosilicate, Transfer 0.6-1.2 parts of ytterbium acetate, 2-4 parts of dispersant POLYRON, 0.6-0.9 parts of 701 powder reinforcing agent and 80-100 parts of aluminum into the resistance reverberatory furnace for homogenization for 15-30 minutes, and transfer the material into the resistance reverberatory furnace at the same time Within 5 minutes of homogenization, add Al-Ti-B wire refiner for the first time to refine the grains, and after 15 minutes of hom...

Embodiment 1

[0033] An aluminum alloy strip for a mobile phone battery case, comprising the following raw materials in parts by weight: 1.2 parts of silicon, 1.5 parts of iron, 4 parts of copper, 0.8 parts of magnesium, 0.3 parts of manganese, 3 parts of zinc, 8 parts of titanium, tin 1.8 parts, 0.8 parts of chromium, 3 parts of nickel, 0.2 parts of graphene, 0.6 parts of sodium fluorosilicate, 0.6 parts of ytterbium acetate, 2 parts of dispersant POLYRON, 0.6 parts of 701 powder reinforcing agent and 80 parts of aluminum;

[0034] The preparation method of the aluminum alloy strip for the cell phone battery case comprises the following steps:

[0035]S1. Melting: Use a gas reactor to melt the prepared materials. After melting, the unit of weight is 1.2 parts of silicon, 1.5 parts of iron, 4 parts of copper, 0.85 parts of magnesium, 0.3 parts of manganese, 3 parts of zinc, and 8 parts of titanium. 1.8 parts of tin, 0.8 parts of chromium, 3 parts of nickel, 0.2 parts of graphene, 0.6 parts ...

Embodiment 2

[0041] An aluminum alloy strip for a mobile phone battery case, comprising the following raw materials in parts by weight: 2 parts of silicon, 2 parts of iron, 5 parts of copper, 0.9 parts of magnesium, 0.5 parts of manganese, 4 parts of zinc, 9 parts of titanium, tin 1.9 parts, 0.9 parts of chromium, 4 parts of nickel, 0.3 parts of graphene, 0.7 parts of sodium fluorosilicate, 0.8 parts of ytterbium acetate, 3 parts of dispersant POLYRON, 0.7 parts of 701 powder reinforcing agent and 90 parts of aluminum;

[0042] The preparation method of the aluminum alloy strip for the cell phone battery case comprises the following steps:

[0043] S1. Melting: Use a gas reactor to melt the prepared materials. After melting, the unit of weight is 2 parts of silicon, 2 parts of iron, 5 parts of copper, 0.9 parts of magnesium, 0.5 parts of manganese, 4 parts of zinc, and 9 parts of titanium. 1.9 parts of tin, 0.9 parts of chromium, 4 parts of nickel, 0.3 parts of graphene, 0.7 parts of sodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com