Deformation heat treatment process to improve the performance of high-strength heat-resistant deformed magnesium alloy cylindrical parts

A technology of deformation heat treatment and heat resistance deformation, which is applied in the field of deformation heat treatment technology to improve the performance of high-strength heat-resistant deformed magnesium alloy cylindrical parts, can solve the problems of uneven structure and performance of the alloy, low material utilization rate, etc., and achieve uniform structure and performance. Effect of improving mechanical properties and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

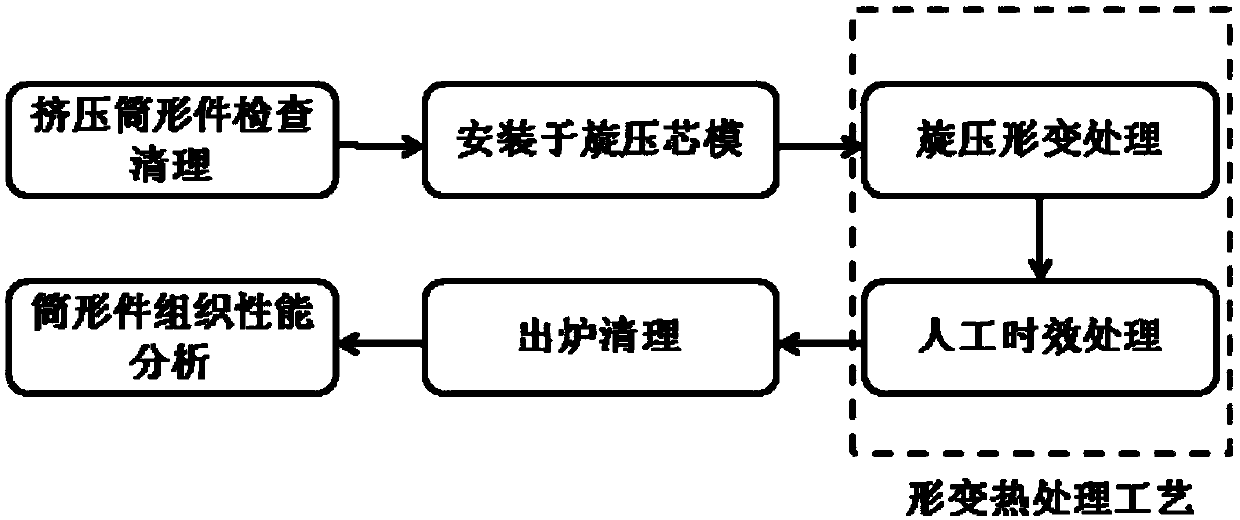

[0034] Such as figure 1 As shown, a deformation heat treatment process for improving the performance of WE71M high-strength heat-resistant deformed magnesium alloy cylindrical parts, the process steps include:

[0035] (1) Scrub the surface of WE71M cylindrical parts with alcohol to remove surface oil stains, ensure that no stains, oil stains, and metal chips are allowed on the surface, and install them on the spinning mandrel tooling after cleaning, such as Figure 7a and Figure 7b shown;

[0036] (2) Heat the WE71M cylindrical piece. When the temperature reaches 480°C, according to the set spinning parameters, the mandrel rotates at 75r / min during the spinning process; Deformation by pass, plastic surgery by pass, the total deformation is not less than 35%;

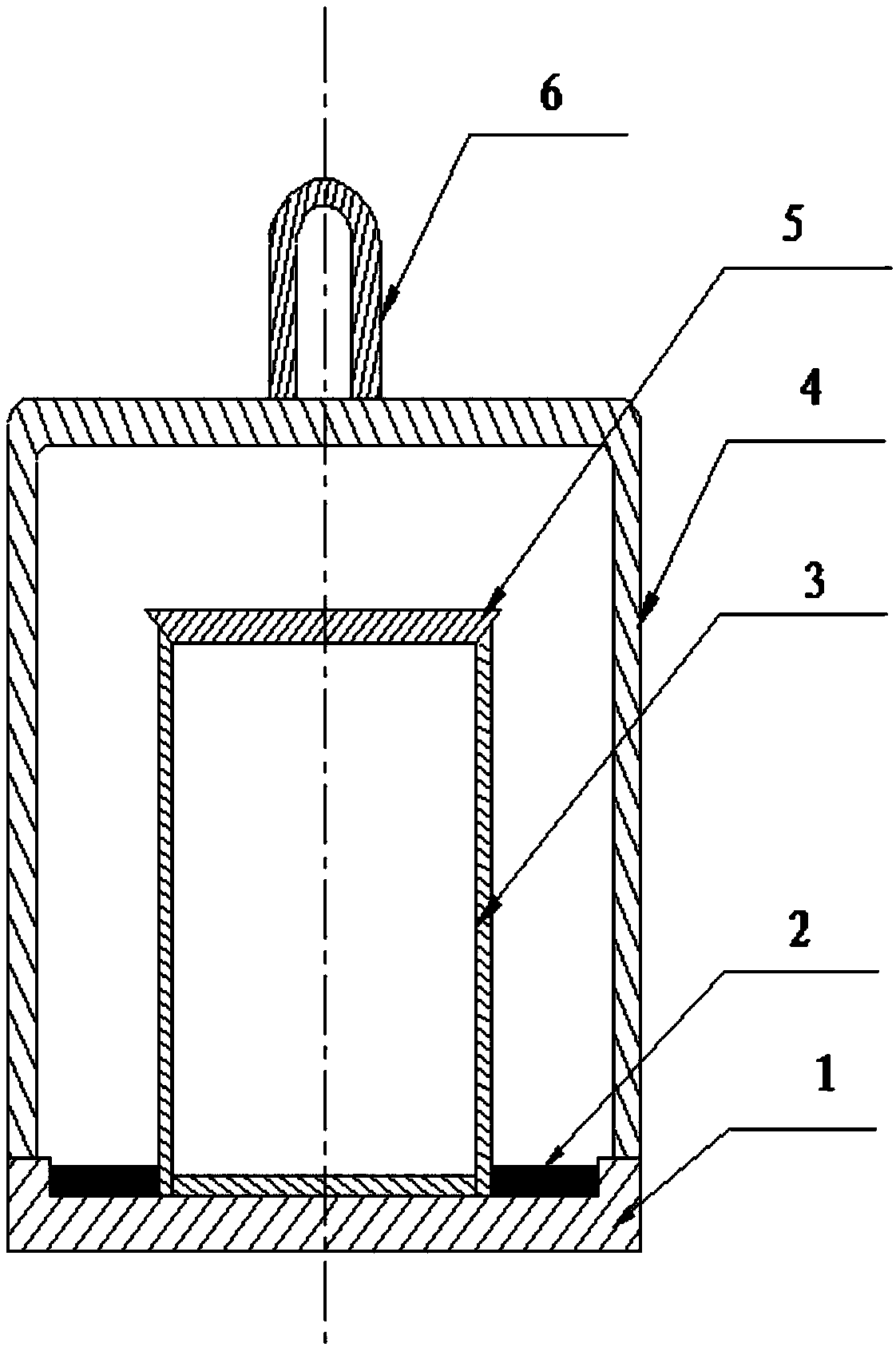

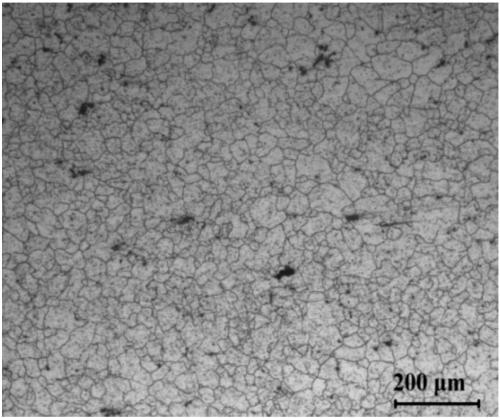

[0037] (3) After the WE71M cylindrical part after spinning is demoulded and cooled to room temperature, install the WE71M cylindrical part on the heat treatment tooling, such as figure 2 As shown, and its installa...

Embodiment 2

[0043] A deformation heat treatment process for improving the performance of WE71M high-strength heat-resistant deformed magnesium alloy cylindrical parts, the process steps include:

[0044] (1) Scrub the surface of WE71M cylindrical parts with alcohol to remove surface oil stains, ensure that no stains, oil stains, and metal chips are allowed on the surface, and install them on the spinning mandrel tooling after cleaning;

[0045] (2) Heat the WE71M cylindrical part. When the temperature is heated to 500°C, according to the set spinning parameters, the mandrel rotates at 75r / min during the spinning process; Deformation by pass, plastic surgery by pass, the total deformation is not less than 35%;

[0046] (3) After the spinning WE71M cylindrical part is demoulded and cooled to room temperature, aging heat treatment is performed on the WE71M cylindrical part. The aging temperature is 225°C and the aging time is 24h. After the aging treatment, it is air-cooled and cooled to roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com