An asphalt pavement structure for heavy traffic

An asphalt pavement and traffic technology, applied in the field of asphalt pavement structure, can solve the problem of not fully understanding the structural stress characteristics and functional requirements of the structural layer to play a role, and achieve good bonding and waterproofing effect, good anti-skid performance, maintaining Long-lasting color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

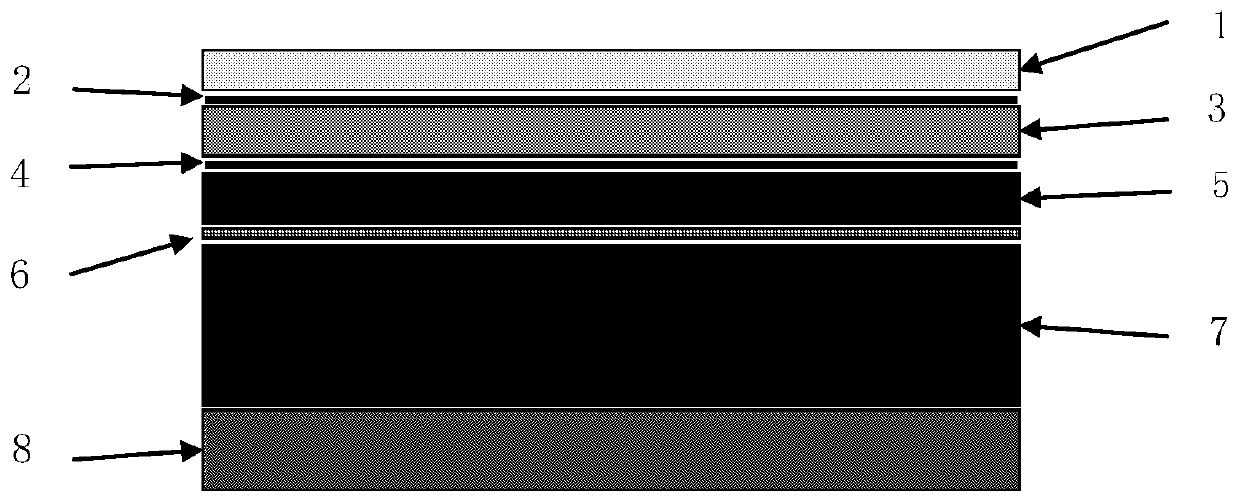

Image

Examples

Embodiment 1

[0024] A gravel mining highway with two lanes in both directions and a width of 7.5m. It was originally an asphalt concrete pavement. Due to heavy loads, the asphalt pavement has severe rutting, large areas of potholes, and water damage that have destroyed the integrity of the base layer and needs to be remodeled. The proportion of large muck trucks with a total load of more than 120 tons in the traffic composition of this road accounts for about 90%. The axle load conversion is carried out according to the asphalt pavement, and the accumulated equivalent axle times within the design period of the lane are 9.0×108 times / lane. The overlay plan that can be used is: 4cm rubber modified asphalt mixture SMA-13+SBS modified emulsified asphalt+8cm high modulus rubber asphalt mixture HMAC-20+SBS modified emulsified asphalt+10cm high performance rubber asphalt concrete Sup -25+1cm rubber asphalt stress absorbing layer SAMI+32cm cement stabilized macadam base +16cm low dose cement stabil...

Embodiment 2

[0026] A newly built expressway with two-way four-lane, width 11.5m, design speed 120Km / h, the proportion of large trucks accounted for about 50% of the predicted traffic composition, according to the axle load conversion of the asphalt pavement, the cumulative equivalent axle times within the design period of the lane is 7.0 ×107 times / lane. The overlay plan that can be used is: 4cm rubber modified asphalt mixture SMA-13+SBS modified emulsified asphalt+6cm high modulus rubber asphalt mixture HMAC-20+SBS modified emulsified asphalt+8cm high performance rubber asphalt concrete Sup -25+1cm rubber asphalt stress absorbing layer SAMI+36cm cement stabilized macadam base +20cm low dose cement stabilized macadam. Among them, the rubber-modified asphalt used in the wear layer SMA-13 has a softening point of 82°C, a ductility (5cm / min, 5°C) of 36cm, and a dynamic viscosity of 47266Pa.s at 60°C; the high-modulus rubber used in the load-bearing layer HMAC-20 The penetration of asphalt...

Embodiment 3

[0028] A third-level county road, two-way two-lane, with a road width of 8.5 meters and a design speed of 60Km / h. It is an important heavy-duty resource road in this area. A cement plant with an annual output of 3 million tons of clinker is distributed in this road section , 2 gravel processing plants with an annual output of more than 2 million tons and other industrial and mining processing enterprises. It was originally an asphalt concrete pavement. Due to the heavy load, the asphalt pavement has serious rutting, large areas of potholes, and water damage, which has destroyed the integrity of the base layer and needs to be remodeled. The proportion of large muck trucks with a total load of more than 120 tons in the traffic composition of this road accounts for about 70%. The axle load conversion is carried out according to the asphalt pavement, and the cumulative equivalent axle times within the design period of the lane is 7.2×107 times / lane. The overlay plan that can be us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com