Pipe foundation dewatering construction method adopted during buried pipe construction

A technology for foundation precipitation and construction methods, which is applied in excavation, waterway systems, water supply devices, etc., can solve problems such as difficult construction, cumbersome equipment installation, and silt at the bottom of the tank, so as to improve water collection capacity, increase seepage stability, The effect of improving water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

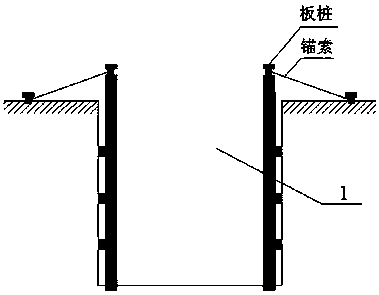

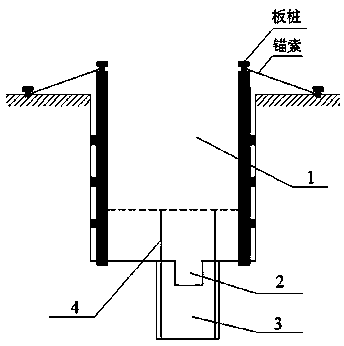

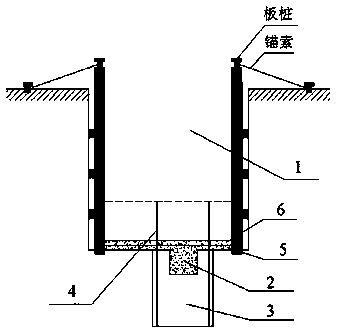

[0040] The engineering background of this buried pipe construction operation is the construction of a section of rain and sewage combined drainage pipeline with a length of about 6Km. The originally designed rain-sewage confluence pipe is a DN600HDPE double-wall corrugated pipe, with a design depth of 2.2m at the bottom of the pipe, and a socket-type hot-melt connection. The excavation depth of the pipe trench is 3.4m, using sheet piles to protect the wall, and the net width of the trench bottom is DN600+0.6m. The design of the ditch foundation treatment requires that the original soil with a thickness of 80 cm in the lower layer be tamped and backfilled in layers, with a compaction degree of over 95%, the middle layer of 30 cm thick lime soil should be replaced and compacted, and the upper layer should be a 100 mm thick sand cushion with a particle size of 8 to 15 mm.

[0041] The current problems encountered in the background project construction precipitation:

[0042] Som...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com