White light laser light source packaging method

A technology of white light laser and packaging method, which is applied in the field of lighting, can solve the problems of complex process, no laser white light source, and low efficiency, and achieve the effects of high light extraction efficiency, high visible light transmittance, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

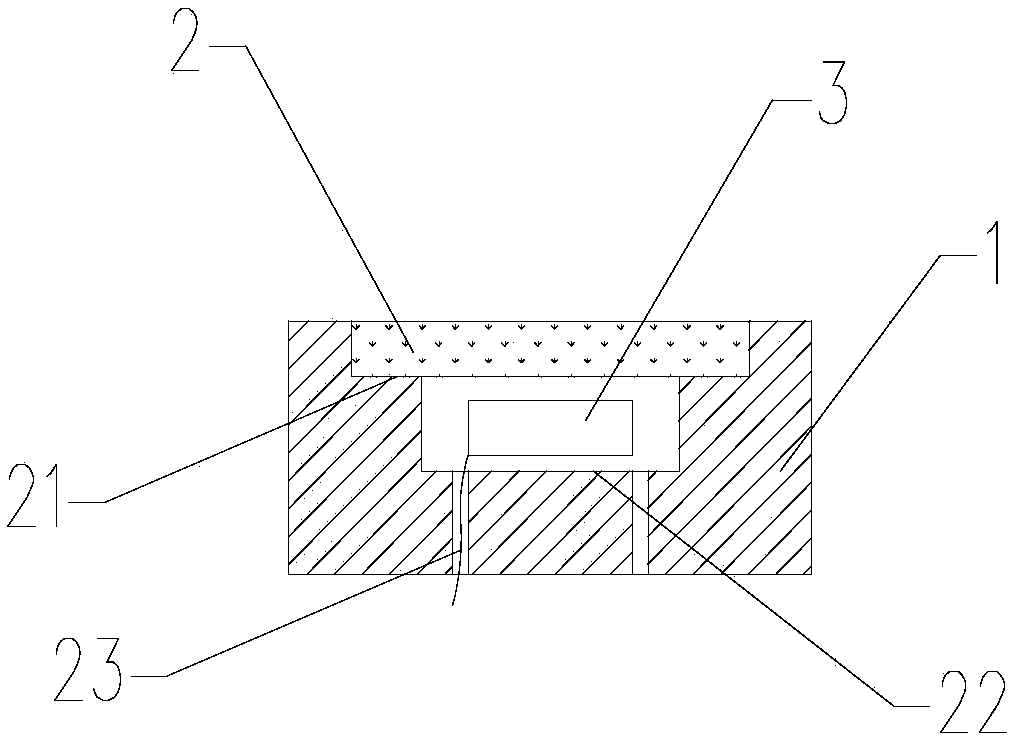

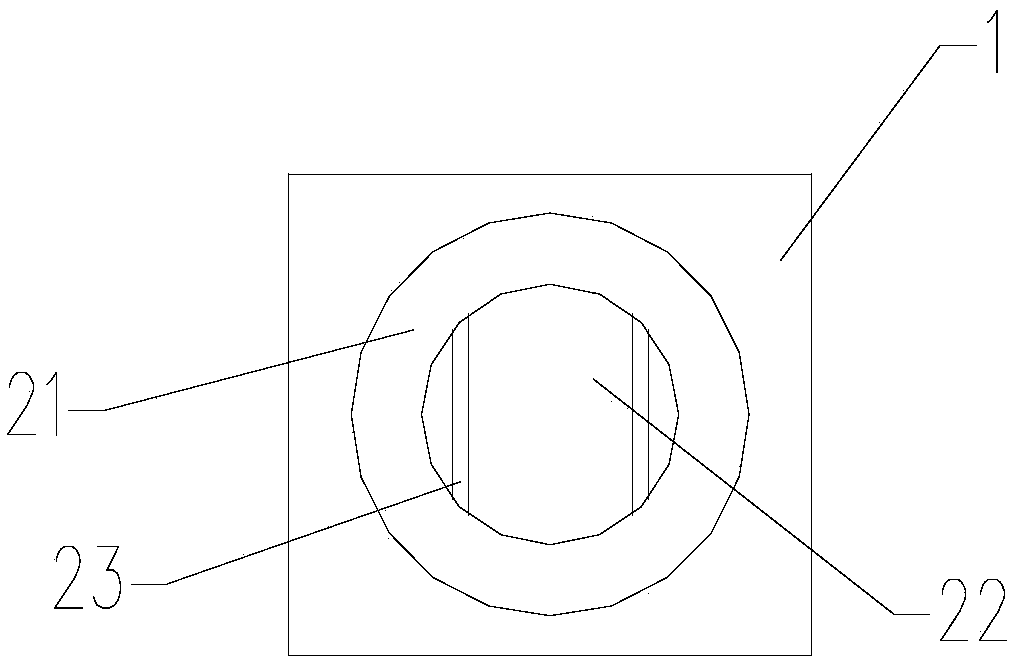

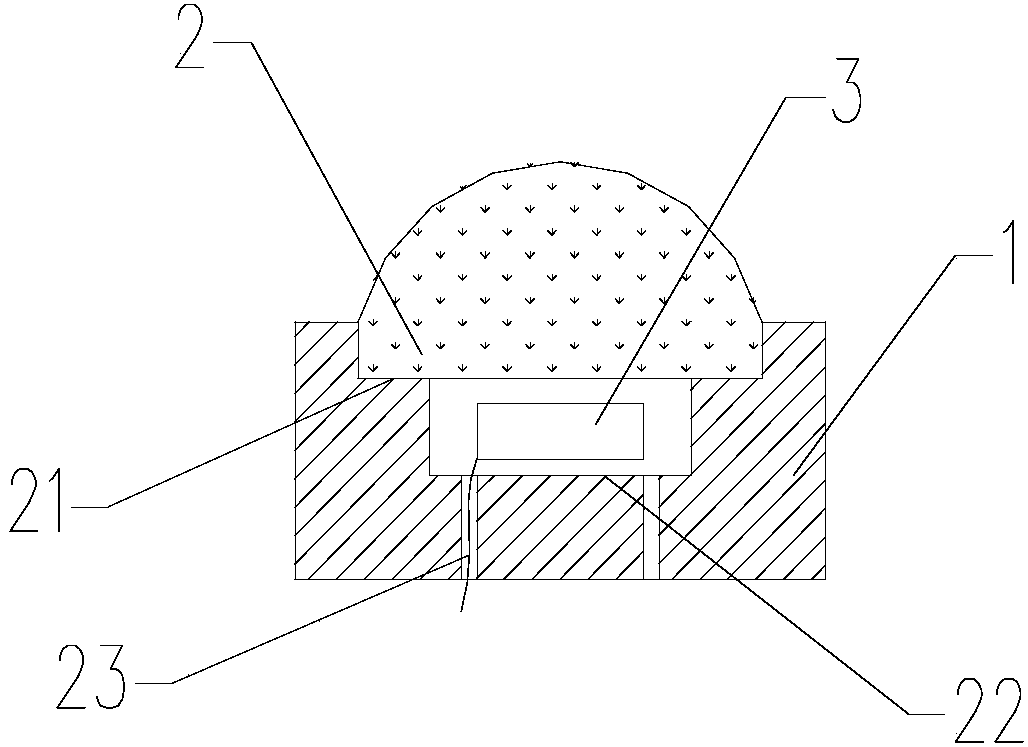

[0039] Such as figure 1 and 2 As shown, it is a schematic diagram of the first structure of the packaging structure of the white light laser light source in the present invention. A packaging structure of a white light laser light source, including a ceramic support 1, a laser chip 2 and a light conversion medium 3, the laser chip 2 is welded on the ceramic support 1 by flip chip or eutectic method, or the chip 2 is bonded with glue in the front mounting process On ceramic support 2. The ceramic support 1 is covered with a light conversion medium 3 for laser conversion to white light, and the blue laser light emitted by the laser chip 2 passes through the light conversion medium 3 and is then excited and converted into white light. The main component of the ceramic stent 1 is alumina or aluminum nitride. The interior of the ceramic support 1 is provided with a cavity, and a step 21 is provided on the side wall of the cavity, the optical conversion medium 3 is fixed on the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Light wavelength | aaaaa | aaaaa |

| Emission wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com