Drying method of flos chrysanthemi

A technology of chrysanthemum and drying room, which is applied in the direction of drying, drying machine, and static material drying machine. The effect of the complete form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

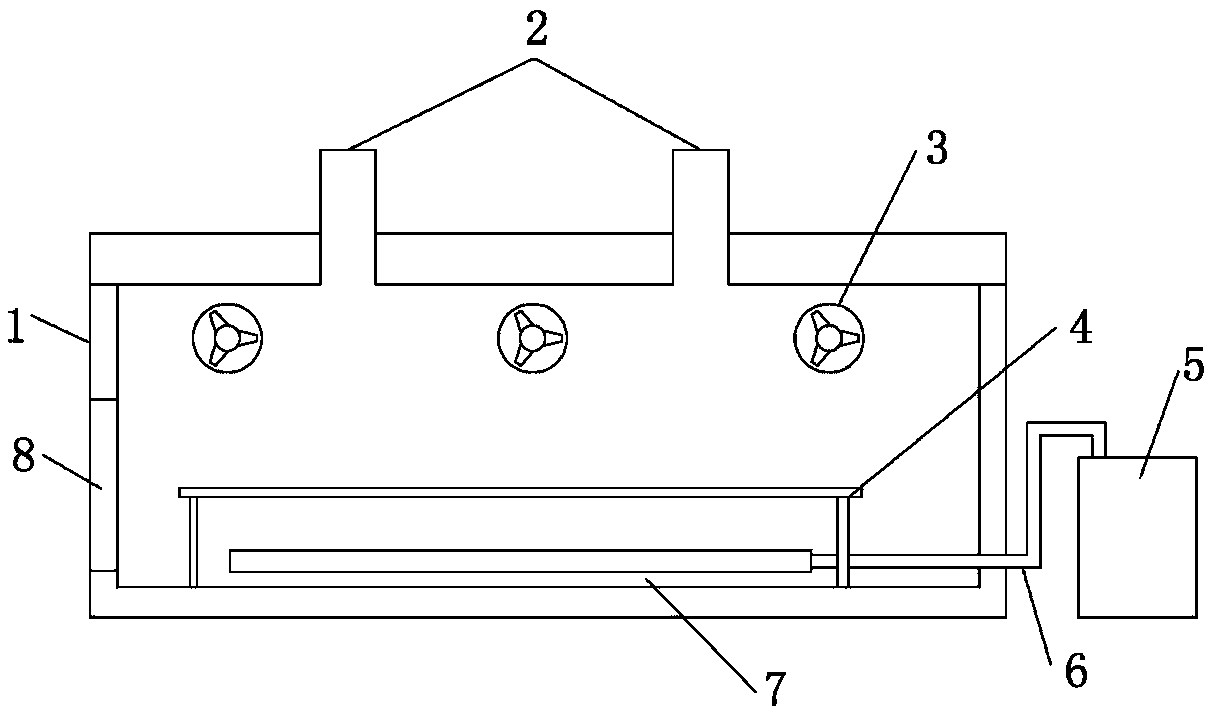

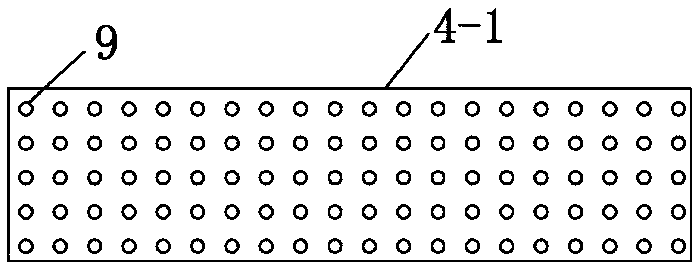

[0011] The hot air drying room structure that the present invention adopts: as Figure 1-Figure 2 As shown, including the drying room 1, the middle of the drying room 1 is an operation channel, and there are drying brackets 4 arranged on both sides along the length direction in the drying room, and the table 4-1 of the drying bracket is made of stainless steel plate. A plurality of hot air passing holes 9 are arranged on the table of the drying support. The diameter of the hot air passing holes 9 is 6-10 mm. The plurality of hot air passing holes 9 are arranged in a rectangular array, and the row spacing and column spacing are 6- 10 mm; hot air exhaust pipe 7 is placed at the bottom of the drying bracket (there are multiple exhaust ports on the wall of the hot air exhaust pipe 7 to realize hot air discharge), and a hot air generator is installed outside the drying room 5. The hot air generator 5 is connected to the hot air exhaust pipe 7 through the pipeline 6; the wall of the...

Embodiment 2

[0013] Adopt the hot air drying room of embodiment 1 to realize the method for drying chrysanthemums: put fresh chrysanthemums on the table top of the drying support, lay the thickness of 10 cm, start the hot air generator, and adjust the temperature in the drying room to be 30-35°C, keep for 3 hours; then, adjust the temperature in the drying room to 55-59°C, keep the temperature for 18 hours; then, turn off the hot air generator, when the temperature in the drying room drops to 40°C, Transfer the chrysanthemums from the drying room to obtain dried chrysanthemums with a water content of 10-12%.

Embodiment 3

[0015] Adopt the hot air drying room of embodiment 1 to realize the method for drying chrysanthemums: lay fresh chrysanthemums on the table top of drying support, lay thickness 8 centimetres, start hot air generating furnace, adjust the temperature in the drying room to be 25-28°C, keep for 4 hours; then, adjust the temperature in the drying room to 60-65°C, keep the temperature for 19 hours; then, turn off the hot air generator, when the temperature in the drying room drops to 40°C, The chrysanthemums are transferred from the drying room to obtain dried chrysanthemums with a water content of 8-9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com