Linear optical fiber array

An optical fiber array and linear technology, applied in the field of linear image information transmission and linear optical fiber array, can solve the problems of vertical position error, inconsistent slot width, depth error and other problems of the end face of the optical fiber array, and achieve the effect of eliminating horizontal cumulative error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

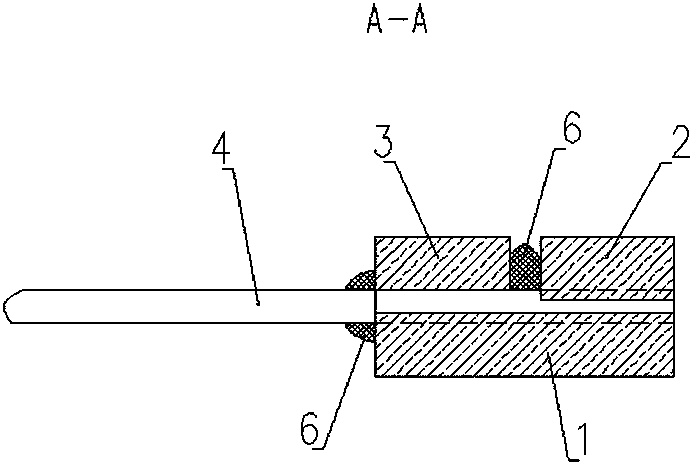

[0031] The upper surface of the bottom plate (1) is successively adjacent to and arranged in parallel with several trapezoidal grooves I (101) with the same structure, the trapezoidal grooves I (101) are isosceles trapezoidal grooves, and the center distances of adjacent trapezoidal grooves are the same;

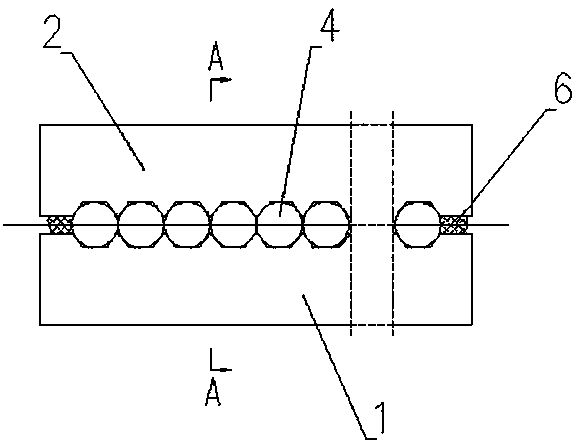

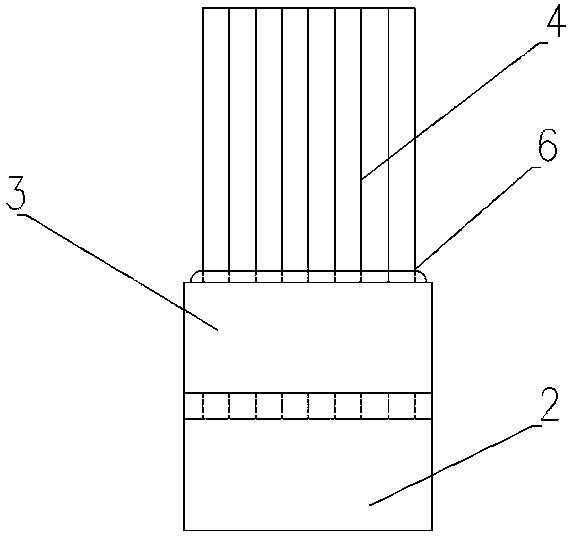

[0032] figure 1 It is the front view of the linear optical fiber array of the present invention, figure 2 is a top view of the linear optical fiber array of the present invention, image 3 for figure 1 A-A direction view in, Figure 4 It is a schematic diagram of the bottom plate structure in the present invention, Figure 5 It is a schematic diagram of the structure of the silicon cover plate in the present invention. exist Figure 1~5 Among them, a linear optical fiber array of the present invention includes a base plate 1, a cover plate above the base plate 1, and several bare optical fibers between the base plate 1 and the cover plate with the coating layer remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com