Shutoff energy recovery method and circuit

An energy recovery and circuit technology, applied in the direction of electrical components, high-efficiency power electronic conversion, output power conversion devices, etc., can solve the large turn-off loss of the main switch tube, increase the turn-off loss of the auxiliary switch tube, and unfavorable power module miniaturization and other issues to achieve the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

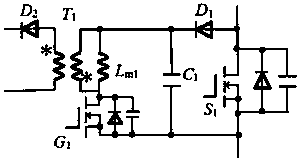

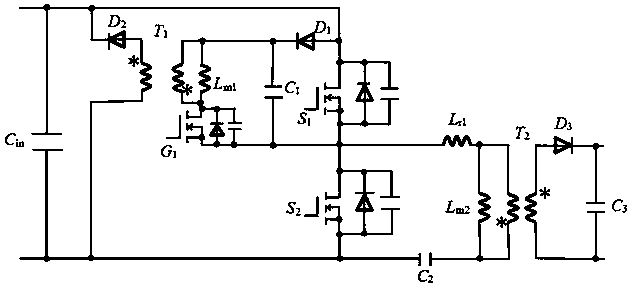

[0035] figure 2 It is a schematic diagram of the first embodiment of the turn-off energy recovery circuit of the switch of the present invention, wherein the unidirectional conduction module is composed of a diode D1, the energy storage module is composed of a capacitor C1, the energy feedback module is a DC-DC converter, and the DC-DC The converter is composed of a flyback circuit. The flyback circuit includes a transformer T1, a primary circuit formed by the primary winding of the transformer T1, and a secondary circuit formed by the secondary winding of the transformer T1; the primary circuit of the flyback circuit also includes The switch G1, the secondary side circuit also includes a diode D2.

[0036] The connection relationship of the first embodiment of the turn-off energy recovery circuit of the switch of the present invention is as follows:

[0037] The anode of the diode D1 is taken as the first input terminal of the shutdown energy recovery circuit, which is used...

no. 2 example

[0050] The principle diagram of the second embodiment is the same as that of the first embodiment, but the control method is different. The switch G1 and the switch S1 are turned on at the same time, but the turn-on time of the switch G1 is fixed. After the switch G1 is turned on, the excitation inductance Lm1 releases energy to the power supply terminal through the diode D2. The working principle differs from that of the first embodiment in that the on-off sequence method is different, and the process of the diode D1 freewheeling the current of the exciting inductor Lm1 is removed, but the final result is the same, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com