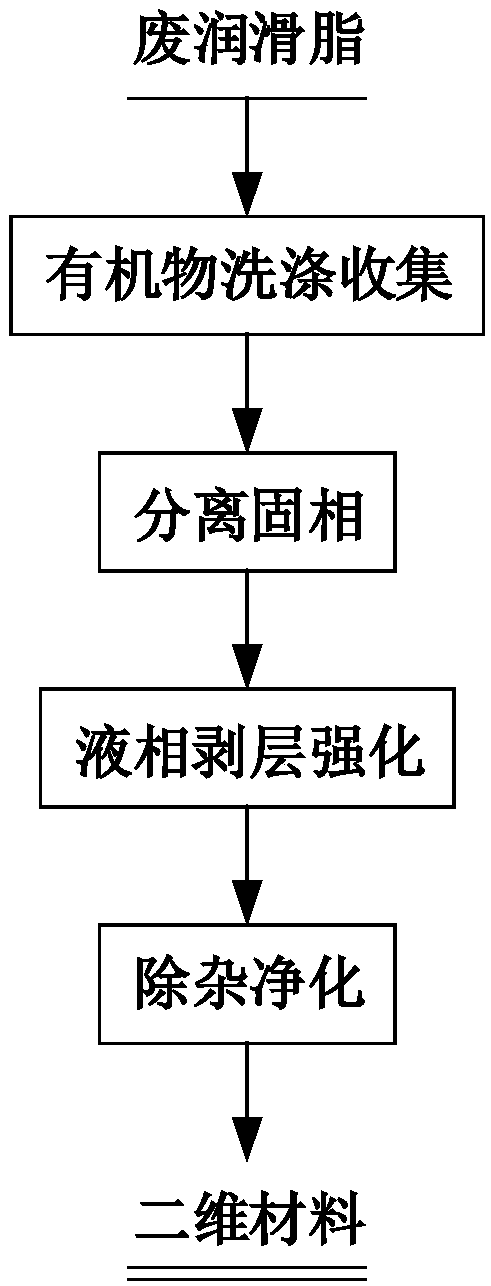

Method for preparing two-dimensional material by using waste grease

A technology of two-dimensional materials and waste grease, applied in lubricating compositions, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of no suitable recycling method, non-reusable, expensive, etc., and achieve less defects and lower regeneration costs Low, quality-controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Use petroleum ether to wash and collect the waste molybdenum disulfide lithium base grease from the lubricating part of a certain mining machinery to obtain 1L of waste grease collection liquid. The mass fraction of waste grease in the waste grease collection liquid is 10wt%. The grease collection solution was stirred at a speed of 100rpm for 2h, then centrifuged at a speed of 200rpm for 0.5h, and the upper liquid phase was obtained and then centrifuged at a speed of 12000rpm for 1h, and the solid particles A collected were dried. , weighing 3.80g, the solid phase particle A is placed in an acidic aqueous solution with a pH of 3.5, and the liquid phase exfoliation is strengthened under the assistance of ultrasonic waves. The mass fraction of the solid phase particle A in the aqueous solution is 0.5wt%, and the solution temperature The temperature is 25°C, the ultrasonic frequency is controlled to 40kHz, and the treatment time is 4h to obtain a solid phase suspension. Th...

Embodiment 2

[0041] Adopt diesel oil to wash and collect waste graphite lithium-based grease from the lubricating part of a certain mechanical manufacturing equipment to obtain 1L of waste grease collection liquid, the mass fraction of waste grease in the waste grease collection liquid is 10wt%, and waste grease The collected liquid was stirred at a speed of 600rpm for 0.5h, and then centrifuged at a speed of 800rpm for 0.5h, and the upper liquid phase was obtained and then centrifuged at a speed of 15000rpm for 1h, and the collected solid particles A were dried. Finally, weighing 2.6g, the solid particle A is placed in an acidic aqueous solution with a pH of 4.0, and the liquid phase exfoliation is strengthened under the assistance of ultrasonic waves. The mass fraction of the solid particle A in the aqueous solution is 3%, and the solution temperature is 50 °C, the ultrasonic frequency is controlled at 100kHz, and the treatment time is 0.5h to obtain a solid phase suspension. The solid p...

Embodiment 3

[0043] Gasoline is used to wash and collect the waste molybdenum disulfide-graphite lithium-based composite grease from the lubricating part of the train mechanical transmission equipment. Obtain 5L of waste lubricating grease collection liquid, the mass fraction of waste lubricating grease in the waste lubricating grease collection liquid is 5wt%, the waste lubricating grease collection liquid is then stirred at a speed of 300rpm for 1h, and then centrifuged at a speed of 300rpm for 1h , obtain the upper liquid phase part and then centrifuge at a speed of 15000rpm for 2h to collect the solid particle A, dry the solid particle A, weigh 7.3g, and place the solid particle A in an acidic aqueous solution with a pH of 1.0. The liquid phase exfoliation strengthening was carried out under the assistance of ultrasonic waves. The mass fraction of solid particles A in the aqueous solution was 8%, the solution temperature was 30°C, the ultrasonic frequency was controlled at 50 kHz, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com