Gas mixing and feeding system used for hydrate preparation experimental device

A technology of gas supply system and experimental device, which is applied in the direction of measuring device, gas fuel, petroleum industry, etc., and can solve the problems of complex synthesis environment, various components of synthesis gas, and long synthesis process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

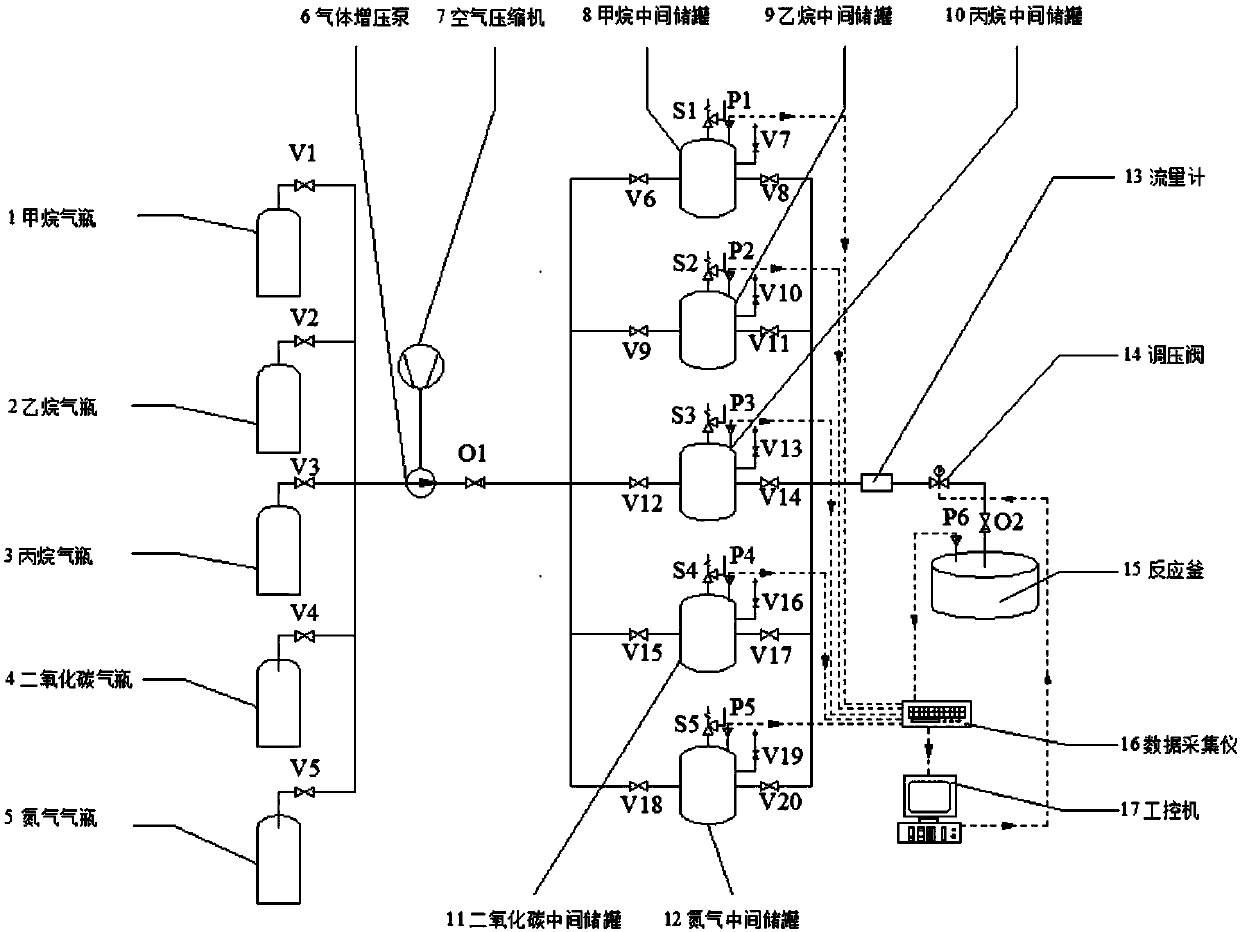

[0024] Example 1: One-component gas supply scheme for hydrate preparation

[0025] When conducting research on the phase equilibrium conditions of single-component gas hydrate synthesis or the synthesis process of single-component gas hydrate, the gas supply scheme of single-component gas can be used. The specific implementation is as follows: when the hydrate preparation experiment starts to supply gas Before, the shut-off valves of the entire gas supply system were all closed. After starting the gas supply experiment, open the cut-off valve V1 or V2 or V3 or V4 or V5 of the corresponding gas cylinder branch according to the predetermined gas selection. Start to deliver gas to the booster pump 6. After the booster pump 6 is full of gas, open the stop valve V6 or V9 or V12 or V15 or V18 at the front end of the branch corresponding to the intermediate storage tank, and start the air compressor 7 and the gas booster pump 6 Start the gas supply, the gas enters the initial stage ...

Embodiment 2

[0026] Example 2: Mixed gas supply scheme for hydrate preparation

[0027] When studying the phase equilibrium conditions of multi-component gas hydrate synthesis or the synthesis process of multi-component gas hydrate, the mixed gas supply scheme of multi-component gas can be adopted. The specific implementation is as follows: When the hydrate preparation experiment starts to supply All shut-off valves of the entire gas supply system are closed before the gas is released. If the two-component gas preparation test is carried out, firstly open the cut-off valve V1 or V2 or V3 or V4 or V5 of the gas cylinder branch corresponding to the first gas, and start to deliver gas to the booster pump 6, after the booster pump 6 is filled with gas , open the cut-off valve V6 or V9 or V12 or V15 or V18 at the front end of the branch of the intermediate storage tank, start the booster pump to start supplying air, when the pressure in the intermediate storage tank 8 or 9 or 10 or 11 or 12 rea...

Embodiment 3

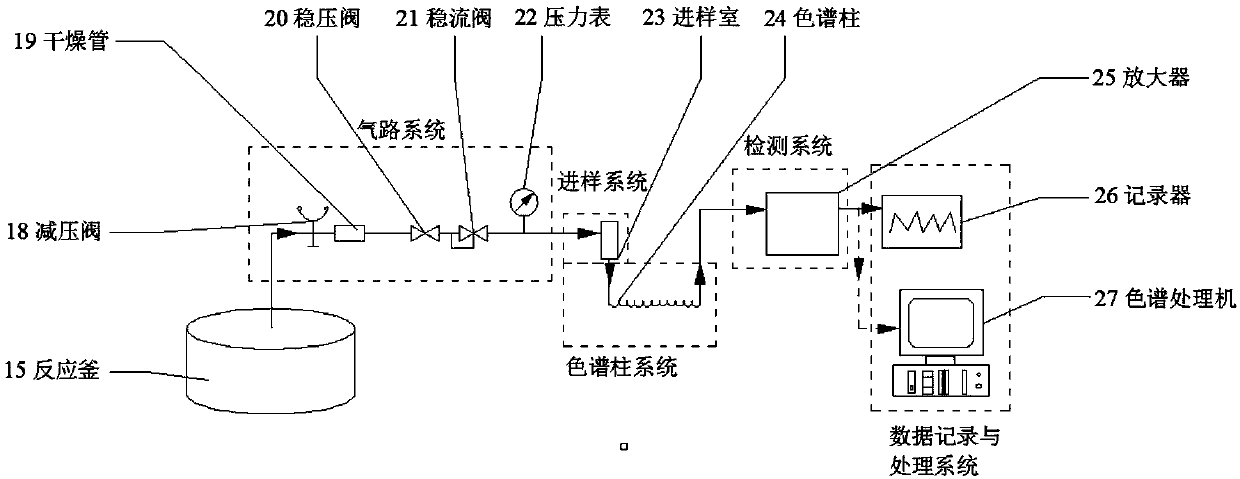

[0037] Example 3: The detection scheme of the proportion of each component after the mixed gas is prepared

[0038] When the mixed gas supply scheme is adopted, in order to further determine the proportion of each component after the mixed gas is prepared, a gas chromatograph can be used to detect the mixed gas. The specific implementation is as follows: , open the pressure reducing valve 18, the pressure stabilizing valve 20, and the steady flow valve 21 of the gas path system of the gas chromatograph, introduce the mixed gas into the sample injection system after drying, stabilizing the pressure, stabilizing the flow, and reducing the pressure of the gas path system, and react The mixed gas in the kettle is sampled in the sampling chamber 23, and the sample is fed to the upper end of the chromatographic column 24 at a uniform speed and quantitatively. Chromatographic column 24 separates the multi-component sample into individual components. When each component of the sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com