Field Weakening Control Method of Built-in Permanent Magnet Synchronous Motor Based on Torque Feedforward Control Technology

A technology of permanent magnet synchronous motor and feedforward control, applied in the field of control system structure based on torque feedforward technology, to achieve the effect of increasing voltage margin, improving torque output capability, and realizing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

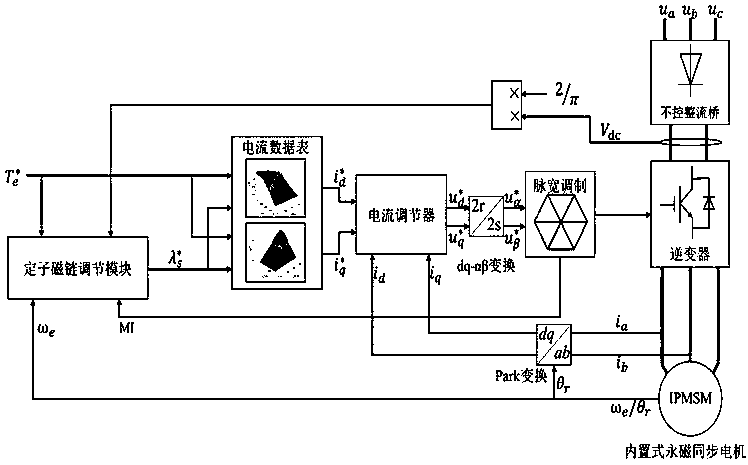

[0026] A structure of the field weakening control method of the built-in permanent magnet synchronous motor based on the torque feedforward control technology of the present invention is as follows figure 1 shown. The software algorithm part includes stator flux adjustment module, current data table, current regulator, pulse width modulation, Transformation and Park Transformation. The hardware part includes uncontrolled rectifier bridge and inverter.

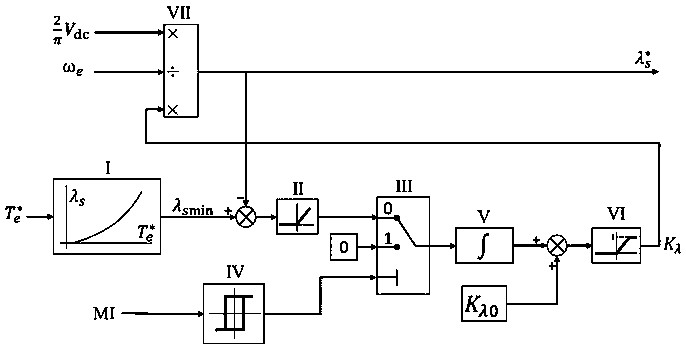

[0027] The stator flux linkage adjustment module calculates a suitable stator flux linkage given value as an output according to the input torque given value, DC bus voltage, motor speed and modulation coefficient.

[0028] The current data table includes two two-dimensional tables. Each table has two input variables: torque reference and stator flux reference. The outputs of the two tables are the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com