Making method of cassava bread

A technology of bread and cassava, which is applied in the direction of dough processing, baking, baked food with modified ingredients, etc., can solve the problem of low application rate of cassava whole powder, and achieve the effect of fine texture and uniform color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

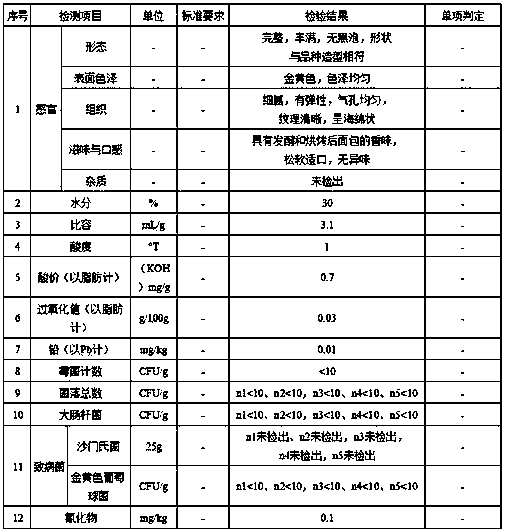

Examples

Embodiment

[0033] This embodiment discloses a kind of preparation method of cassava bread, and the steps are as follows:

[0034] (1) Raw material preparation:

[0035] Flour: including whole cassava flour and high-gluten flour, the mass ratio of whole cassava flour to high-gluten flour is 2:8, the whole cassava flour is made of edible cassava variety Huanan No. 9, the particle size is ≥120 mesh, and the water content is ≤14%;

[0036] White granulated sugar, add 200g white granulated sugar for every 1kg of flour;

[0037] Yeast, add 10g of yeast per 1kg of flour;

[0038] Bread improver, add 3g bread improver per 1kg flour;

[0039] Eggs, add 3 eggs per 1kg of flour;

[0040] For milk, add 450g of milk per 1kg of flour;

[0041] Butter, add 100g of butter for every 1kg of flour;

[0042] Salt, add 10g of salt for every 1kg of flour;

[0043] (2) Stirring: Pour the flour, sugar, yeast, and bread improver into the dough maker according to the proportion by weight, then add eggs and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com