Mold removal agent for feeds and preparation method of mold removal agent

A mold remover and feed technology, applied in the direction of bacteria used in food preparation, food science, food preservation, etc., can solve the problems of ineffective containment of mycotoxin hazards, narrow application range, low mold removal effect, etc., to protect animals Liver and kidney, wide application range, the effect of preventing and treating livestock and poultry mycotoxin poisoning and related diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

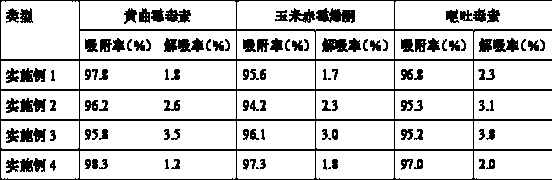

Examples

Embodiment 1

[0023] A feed mildew remover, comprising the following raw materials in parts by weight: 20 parts of chitosan, 18 parts of montmorillonite, 7 parts of tea residue, 6 parts of composite microbial agent, 10 parts of citric acid, 5 parts of aloe, rosin 5 parts and 4 parts of mugwort leaves. The composite microbial agent is prepared by mixing the following raw materials in parts by weight: 5 parts of Bacillus natto, 5 parts of Bacillus subtilis, 3 parts of lactic acid bacteria, 3 parts of Lactobacillus plantarum and 2 parts of Bacillus amyloliquefaciens.

[0024] The present invention also provides a preparation method of a feed mildew remover, which consists of the following steps:

[0025] (1) Weigh each raw material according to the above parts by weight, and set aside;

[0026] (2) Superfinely pulverize chitosan and montmorillonite, add water and stir, then add compound microbial agent, stir evenly, and react with ultrasonic oscillation for 30 minutes. The ultrasonic temperat...

Embodiment 2

[0029] A feed mildew remover, comprising the following raw materials by weight: 15 parts of chitosan, a surface area of 250m 2 10 parts of nano-montmorillonite / g, 5 parts of tea residue, 5 parts of compound microbial agent, 4 parts of citric acid, 3 parts of aloe, 3 parts of rosin and 1 part of mugwort leaves. The composite microbial agent is prepared by mixing the following raw materials in parts by weight: 3 parts of Bacillus natto, 3 parts of Bacillus subtilis, 1 part of lactic acid bacteria, 1 part of Lactobacillus plantarum and 5 parts of Bacillus amyloliquefaciens.

[0030] The present invention also provides a preparation method of a feed mildew remover, which consists of the following steps:

[0031] (1) Weigh each raw material according to the above parts by weight, and set aside;

[0032] (2) Superfinely pulverize chitosan and montmorillonite, add water and stir, then add compound microbial agent, stir evenly, and react with ultrasonic oscillation for 30 minutes. ...

Embodiment 3

[0035] A feed mildew remover, comprising the following raw materials by weight: 35 parts of chitosan, a surface area of 400m 2 25 parts of nano-montmorillonite / g, 10 parts of tea residue, 10 parts of compound microbial agent, 12 parts of citric acid, 8 parts of aloe, 8 parts of rosin and 5 parts of mugwort leaves. The composite microbial agent is prepared by mixing the following raw materials in parts by weight: 3 parts of Bacillus natto, 3 parts of Bacillus subtilis, 1 part of lactic acid bacteria, 1 part of Lactobacillus plantarum and 1 part of Bacillus amyloliquefaciens.

[0036] The present invention also provides a preparation method of a feed mildew remover, which consists of the following steps:

[0037] (1) Weigh each raw material according to the above parts by weight, and set aside;

[0038] (2) Superfinely pulverize chitosan and montmorillonite, add water and stir, then add compound microbial agent, stir evenly, and react with ultrasonic oscillation for 30 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com