A kind of surface silicon oxidation polyimide-co-siloxane film and preparation method thereof

A silicon-oxidized polyimide and polyimide technology, applied in chemical instruments and methods, flat products, other household appliances, etc., can solve the problem of increased material adhesion, cold welding phenomenon has not been better solved, the impact of Problems such as the normal function of the spacecraft mechanism, to achieve the effect of controllable processing conditions and excellent performance

Active Publication Date: 2019-10-01

JILIN UNIV

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The occurrence of cold welding seriously affects the normal function of the spacecraft mechanism, and even leads to flight accidents

In recent years, Japan has developed polyimide-co-siloxane anti-atomic oxygen materials, which exhibit excellent anti-atomic oxygen properties, but due to the introduction of siloxane, the adhesion of the material is greatly increased. The phenomenon of cold welding has not been better resolved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

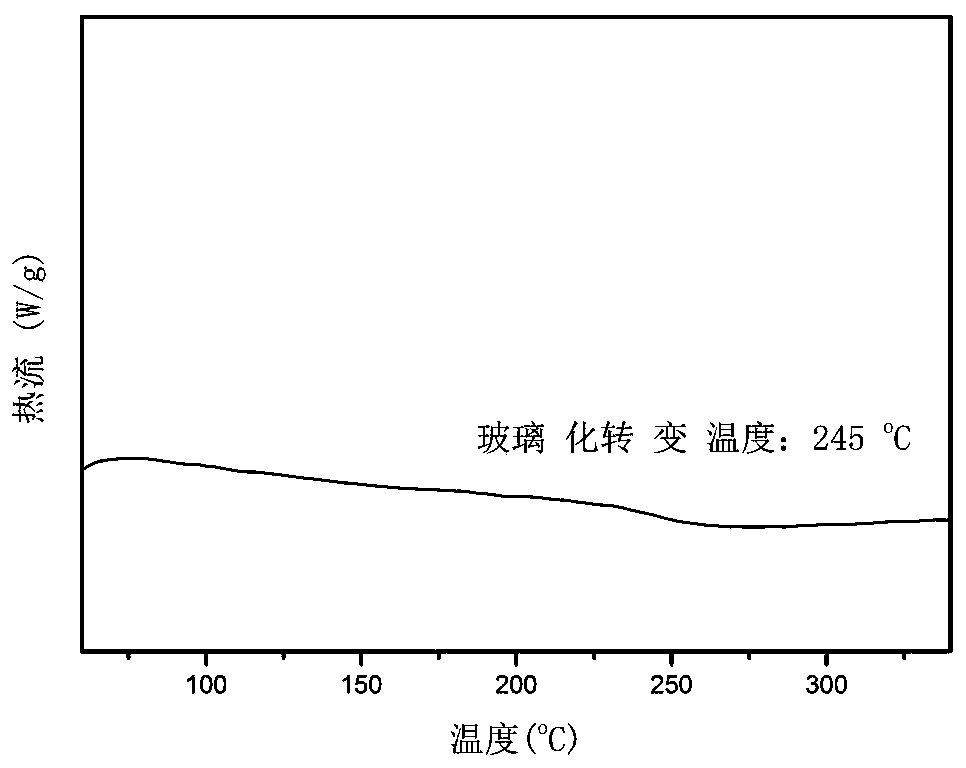

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Login to View More

Abstract

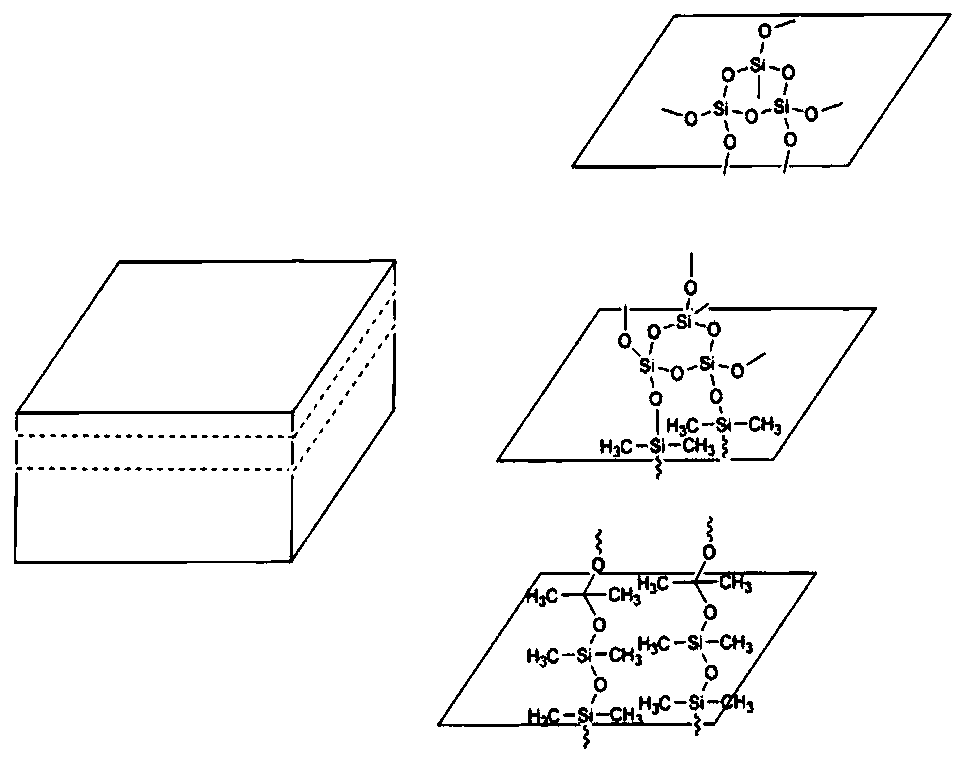

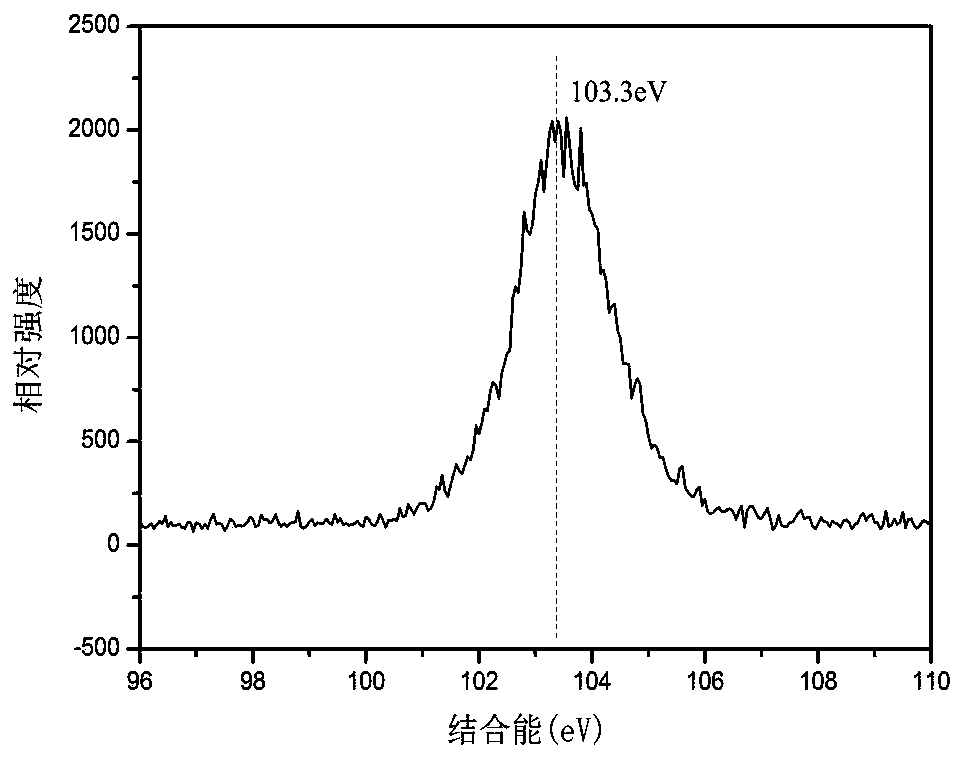

The invention discloses a surface silicon oxidation polyimide-co-silane thin film and a preparation method and belongs to the technical field of polyimide preparation. The invention provides the surface silicon oxidation polyimide-co-silane thin film. The preparation method comprises the following steps: firstly, preparing polyimide-co-silane by adopting a temperature raising and pressurizing method on the basis of a traditional two-step preparation method; and secondly, forming a glass-like functional layer on the surface by controlling conditions and adopting atomic oxygen equipment. The surface silicon oxidation polyimide-co-silane thin film consists of three parts, namely a glass layer, a transition layer and a substrate layer, wherein the glass layer consists of a silicon-oxygen structure, the transition layer consists of the silicon-oxygen structure and the polyimide-co-silane and the substrate layer consists of the polyimide-co-silane. The surface silicon oxidation polyimide-co-silane thin film, disclosed by the invention, has the advantages of excellent atomic oxygen resistance and capability of self-healing. The glass-like functional layer avoids the occurrence of a cold welding phenomenon.

Description

technical field The invention relates to the technical field of polyimide preparation, in particular to a surface silicon oxidation polyimide-co-siloxane film and a preparation method thereof. Background technique After the completion of the space shuttle mission in 1981, a special phenomenon was discovered during the visual inspection of the staff: a significant change occurred on the surface of the thermal control pad of a TV camera made of polyimide film material. The glossy, transparent amber film prior to flight turns a translucent pale yellow. After research, it was found that it was the result of atomic oxygen erosion. Atomic oxygen has begun to attract the attention of the aerospace industry. Researchers from various countries have conducted a lot of research on the mechanism of interaction between atomic oxygen and materials, and have developed different types of anti-atomic oxygen materials. Silicone resin-based coating materials have excellent anti-atomic oxyge...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B32B17/10B32B9/04B32B27/28C08G77/455C08J3/28B29D7/01

Inventor 陈春海王春博姜勃弛姚佳楠周宏伟赵晓刚王大明

Owner JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com