A method for preparing graphene film by ultra-high pressure thermal reduction

A graphene film, graphene film technology, applied in graphene, nano carbon and other directions, can solve problems such as serious energy consumption, reduce thermal conductivity, affect stability and durability, and achieve perfect structure, high electrical conductivity and thermal conductivity. The effect of sex, dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

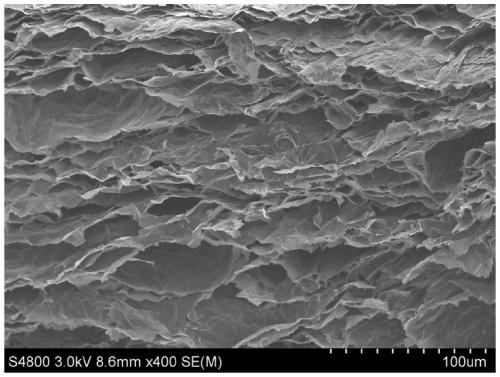

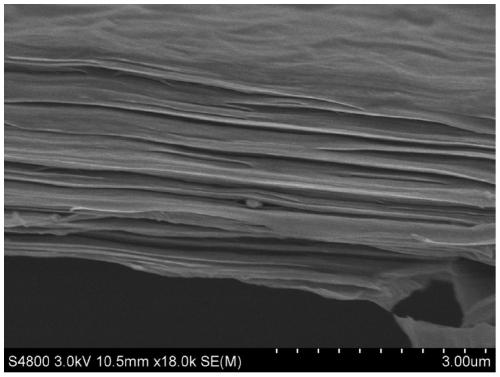

[0021] (1) A single layer of graphene oxide is formulated into an aqueous solution with a concentration of 6 mg / mL, and the solution is naturally dried after forming a film, and then reduced with a reducing agent.

[0022] (2) The reduced graphene film is heated to 300°C at a rate of 0.1°C / min under a hot press, kept for 2h and naturally cooled down; the pressure is maintained at 5GPa throughout the process.

[0023] (3) The above-mentioned graphene film is heated to 1500°C at a rate of 1°C / min under an inert gas atmosphere and kept for 6 hours; the pressure is maintained at 10 GPa throughout the process.

[0024] The obtained graphene film has an AB structure content of 95% and a conductivity of 9300 S / cm.

Embodiment 2

[0026] (1) A single layer of graphene oxide is formulated into an aqueous solution with a concentration of 30 mg / mL, and the solution is naturally dried after forming a film, and then reduced with a reducing agent.

[0027] (2) The reduced graphene film is heated to 400°C at a rate of 5°C / min under a hot press, kept for 0.5h and cooled naturally; the pressure is maintained at 0.5GPa throughout the process.

[0028] (3) The above-mentioned graphene film is heated to 1800°C at a rate of 20°C / min under an inert gas atmosphere for 0.5h; the pressure is maintained at 3GPa throughout the process.

[0029] The obtained graphene film has an AB structure content of 90% and a conductivity of 8500 S / cm.

Embodiment 3

[0031] (1) A few layers of graphene (1-10 layers) or graphite micro-nano flakes (thickness less than 100nm) are formulated into an aqueous solution with a concentration of 16 mg / mL, and the solution is naturally dried after forming a film.

[0032] (2) The graphene film is heated to 350°C at a rate of 1°C / min under a hot press, kept for 1 hour and naturally cooled down; the pressure is maintained at 2GPa throughout the process.

[0033] (3) The above-mentioned graphene film is heated to 1600°C at a rate of 10°C / min under an inert gas atmosphere for 2 hours; the pressure is maintained at 5 GPa throughout the process.

[0034] The AB structure content of the obtained graphene film is 92.3%, and the conductivity is 8800 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com