Synthesizer for high-purity 3-isocyanate propyltriethoxysilane and synthetic method thereof

An ester propyl triethoxy silane and a synthesis device technology are applied in the field of synthesis devices of high-purity 3-isocyanatopropyl triethoxy silane, and can solve the problem of consuming large vacuum pump oil or mineral oil, raw material residues, etc. problem, to achieve the effect of easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

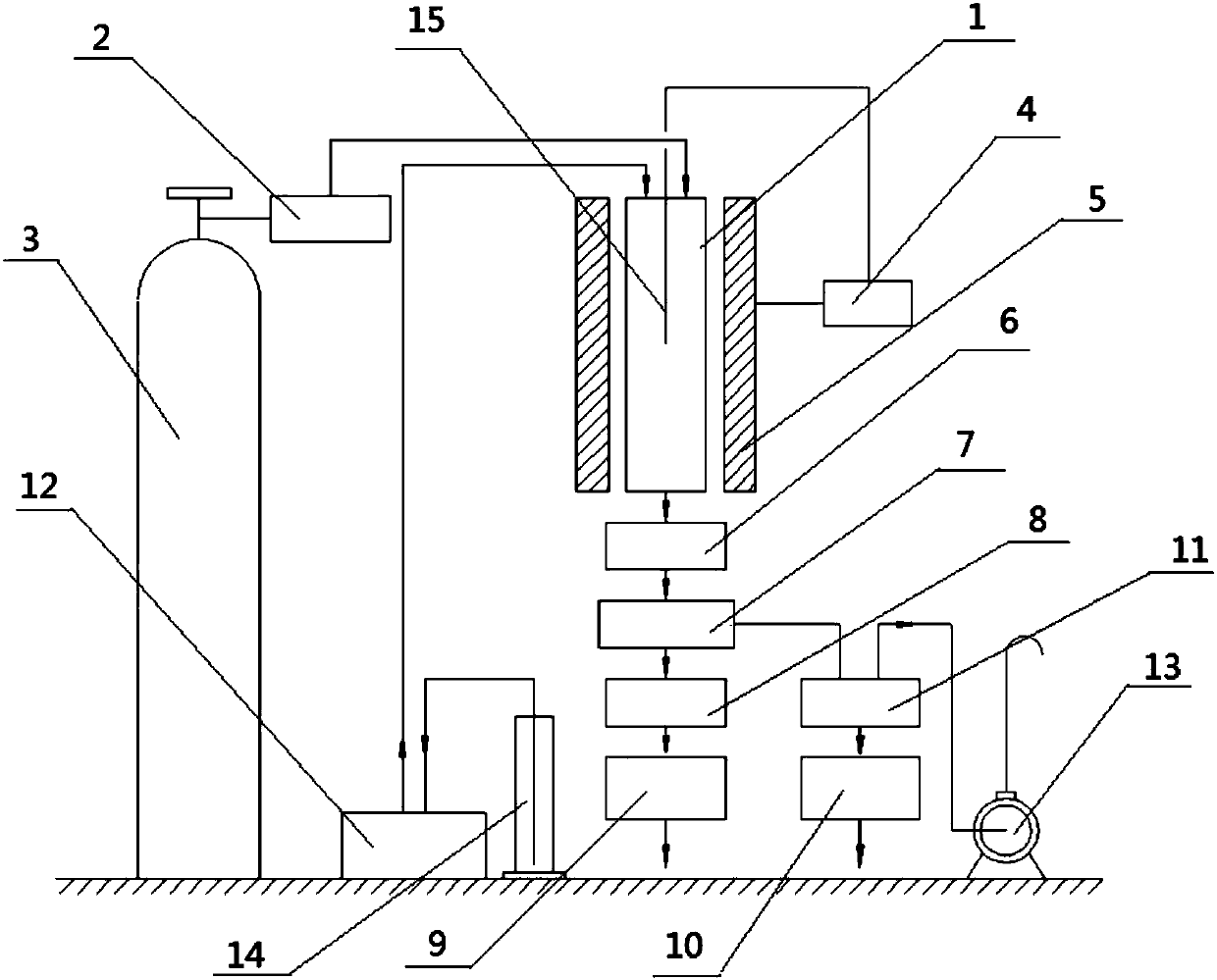

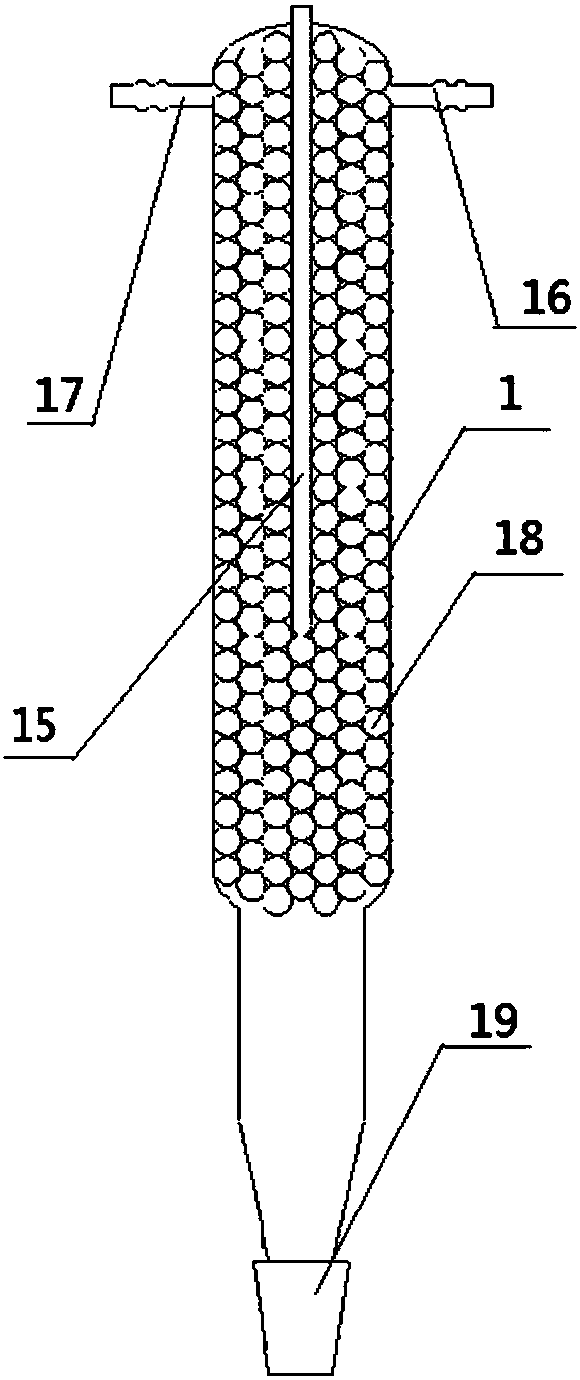

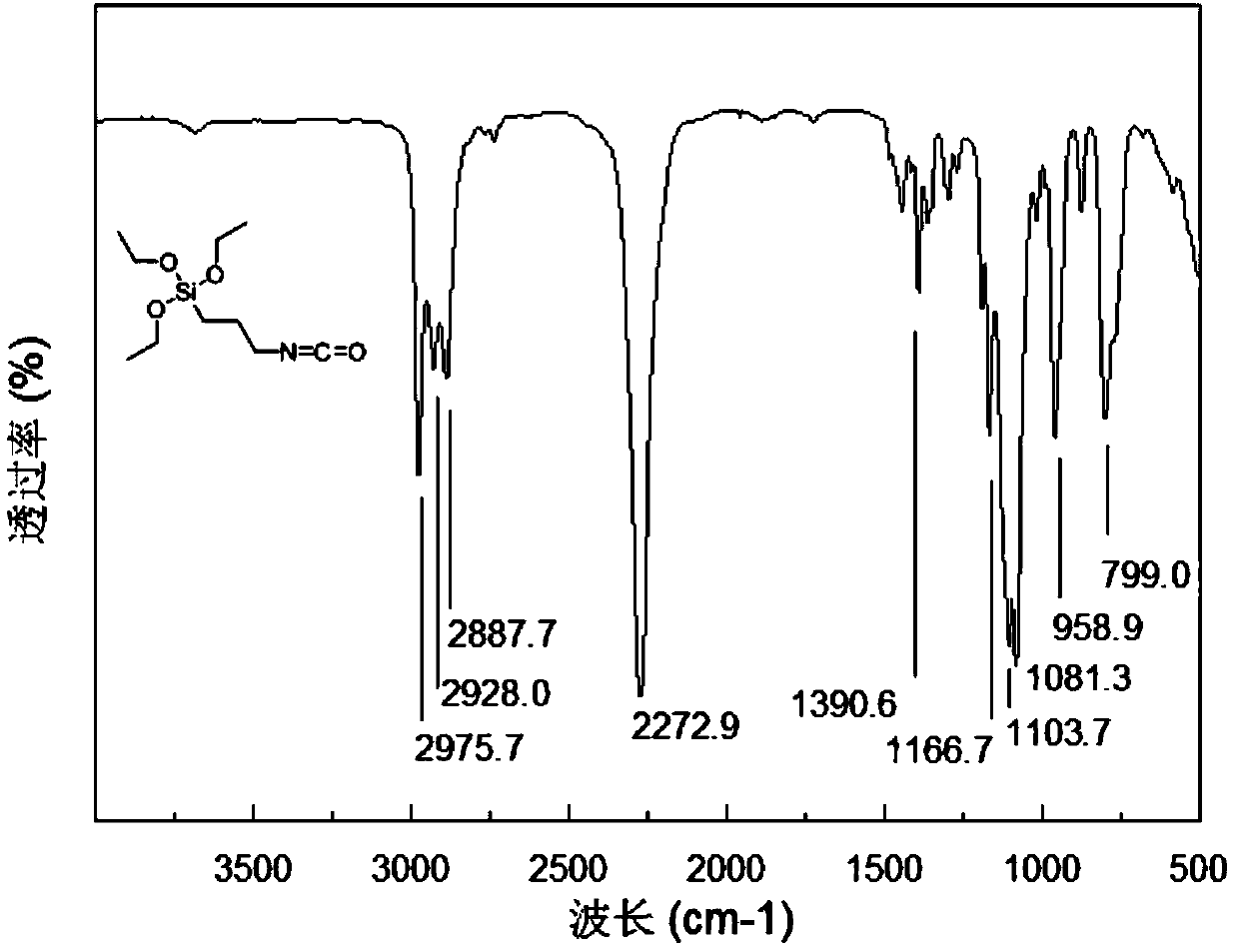

[0036]A kind of synthetic device of high-purity 3-isocyanatopropyl triethoxysilane, the synthetic device of described high-purity 3-isocyanatopropyl triethoxysilane comprises fixed bed reactor 1, described fixed bed Reactor is installed in heating furnace 5, and solid support 18 is housed in the described fixed-bed reactor, and the top of described fixed-bed reactor is provided with feeding port 17, protective gas inlet 16, and described fixed-bed reaction The feed port of the reactor is connected to the metering pump 12 through the pipeline, and the metering pump is connected to the feed box 14 through the pipeline, and the protective gas inlet of the fixed bed reactor is connected to the pressure reducing valve 2 through the pipeline. The pressure reducing valve is connected to the cylinder 3 through a pipeline, and the bottom of the fixed bed reactor is provided with a discharge port 19, and the discharge port is connected to the inlet of the first condenser 6 through a pipe...

specific Embodiment approach 2

[0040] According to the synthetic method of the high-purity 3-isocyanatopropyl triethoxysilane described in specific embodiment one, comprises the steps:

[0041] Step 1. Check the airtightness of the synthesis device of the high-purity 3-isocyanatopropyltriethoxysilane, heat the fixed-bed reactor to 350° C. and keep the temperature for use;

[0042] Step 2. Adjust the pressure reducing valve to pass protective gas into the fixed-bed reactor. After passing the protective gas for 10 minutes, use a metering pump to pass the raw material [3-(triethoxysilyl)propyl] ethyl carbamate into the A fixed-bed reactor for thermal cracking reaction, the reaction time is 2h;

[0043] Step 3, the reacted mixture in step 2 is cooled by the first condenser, and the first condenser is cooled by 80°C hot water, and the cooled mixture enters the gas-liquid separator for separation, and the separated liquid enters the The product receiving tank, the separated gas enters the second condenser, the s...

specific Embodiment approach 3

[0055] According to the synthetic method of the high-purity 3-isocyanatopropyl triethoxysilane described in specific embodiment one, comprises the steps:

[0056] Step 1. Check the airtightness of the synthesis device of the high-purity 3-isocyanatopropyltriethoxysilane, heat the fixed-bed reactor to 370°C and keep the temperature for use;

[0057] Step 2. Adjust the pressure reducing valve to pass protective gas into the fixed-bed reactor. After passing the protective gas for 10 minutes, use a metering pump to pass the raw material [3-(triethoxysilyl)propyl] ethyl carbamate into the A fixed-bed reactor for thermal cracking reaction, the reaction time is 2h;

[0058] Step 3, the reacted mixture in step 2 is cooled by the first condenser, and the first condenser is cooled by 80°C hot water, and the cooled mixture enters the gas-liquid separator for separation, and the separated liquid enters the The product receiving tank, the separated gas enters the second condenser, the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com